Three-control sawing panel running control system

A technology of operation control and sheet metal, which is applied in the field of sheet metal manufacturing, and can solve problems such as chaotic boards, failure of normal cutting of sheets, affecting sheet cutting and operation control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

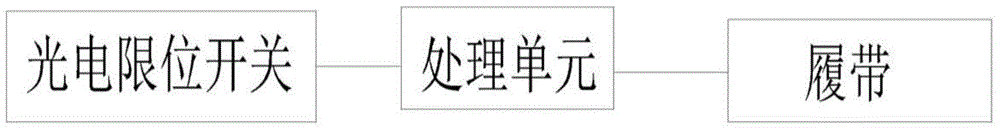

[0007] Such as figure 1 As shown, the three-control sawing board operation control system, the board is conveyed on the crawler belt, and the crawler is equipped with small claws for jacking up the board. The three-control sawing board operation control system includes a photoelectric limit switch and a processing unit. The photoelectric limit switch is 20 centimeters away from the upper direction of the small claw. The photoelectric limit switch inputs the on / off signal to the processing unit, and the processing unit controls the track to stop after receiving the off signal and delaying the specified time.

[0008] When the photoelectric limit switch detects that the stop position of the plate on the track is not suitable, it will send the close signal to the processing unit, and the processing unit will control the track to stop after receiving the close signal and delay the specified time, thus avoiding the stop when the plate enters the track. When the position is not suit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com