Plate conveying mechanism based on building block forming machine

A block forming machine and board feeding technology, which is applied in the direction of destacking, transportation and packaging of objects, can solve the problems of uneven board feeding, large impact force, and disordered board, so as to ensure stability and avoid jamming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

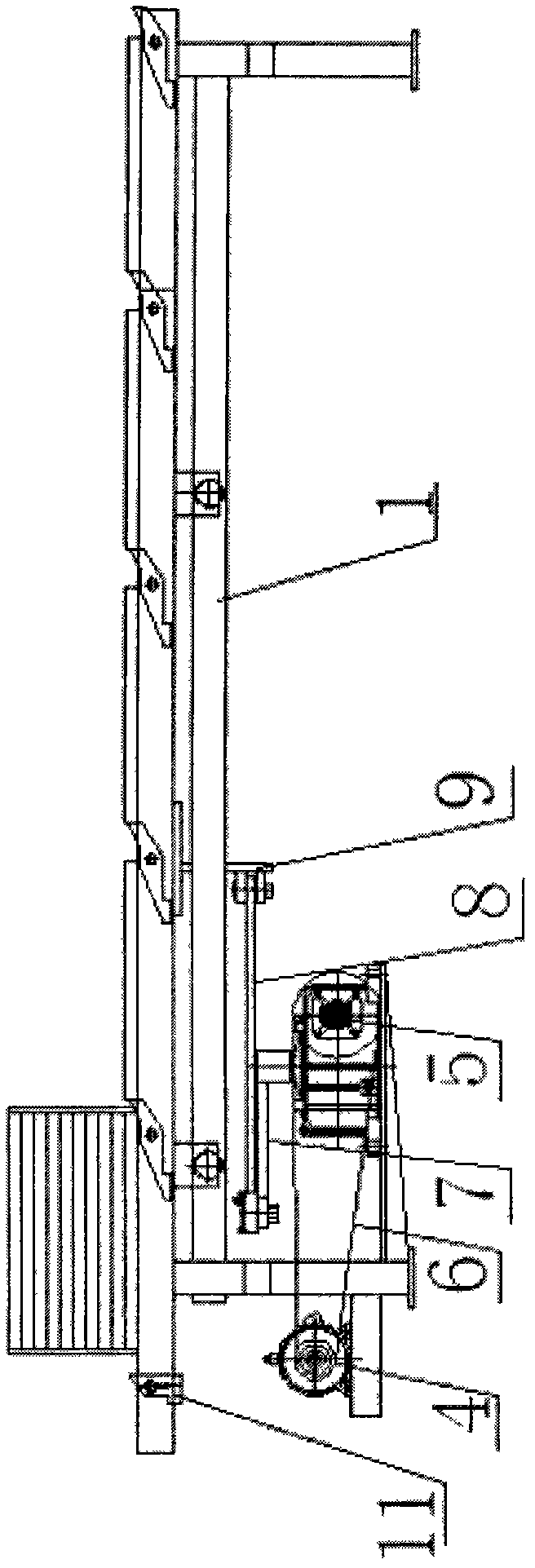

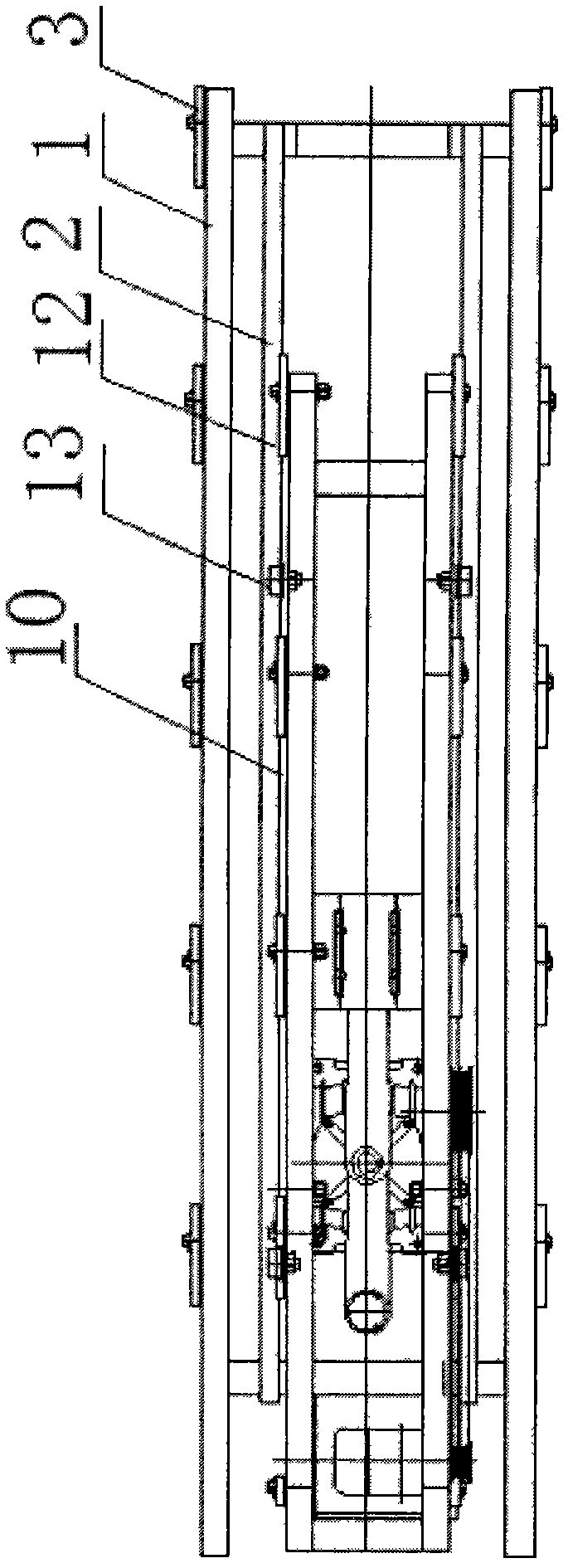

[0013] like figure 1 , 2 As shown, the plate feeding mechanism includes a frame 1, a power mechanism, a transmission mechanism, and a push plate mechanism. The frame 1 is a rectangular parallelepiped with four supporting legs. The frame 1 is provided with two parallel rollers made of channel steel. Guide rail 2, 5 anti-return forks 3 are installed on both sides of the frame 1, the power mechanism includes a motor 4 and a reducer 5 located under the frame 1, the motor 4 and the reducer 5 transmit power through the belt 6, and the transmission mechanism includes Crank 7, connecting rod 8, push-pull plate 9, one end of the crank 7 is connected with the output shaft of the reducer 5, the other end of the crank 7 is connected with the push-pull plate 9 through the connecting rod 8, and the other end of the push-pull plate 9 is connected with the moving frame 10 Fixed connection, the push plate mechanism includes a moving frame 10, a plate feeding fork 12, and a roller 13. Four pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com