Hydraulic heavy duty truck tire disassembly apparatus

A tire and heavy-duty technology, applied in tire installation, vehicle parts, tire parts, etc., can solve the problems of fast disassembly and low labor intensity, achieve high disassembly efficiency, operator safety, and solve the effect of disassembly difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

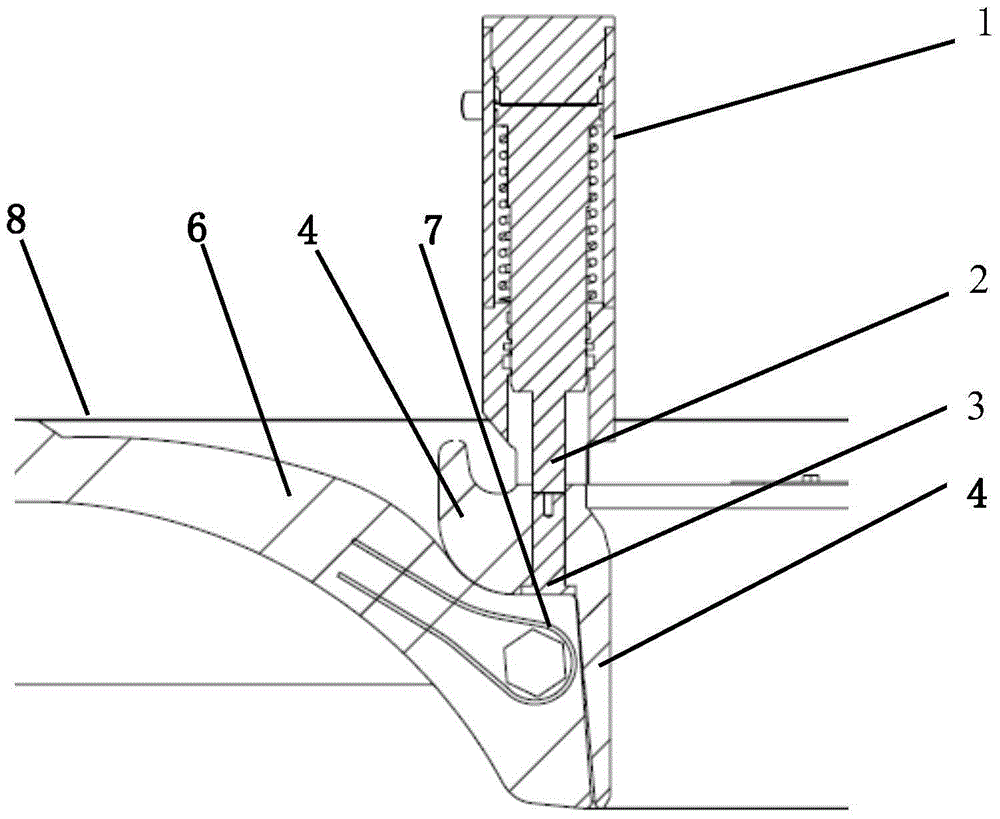

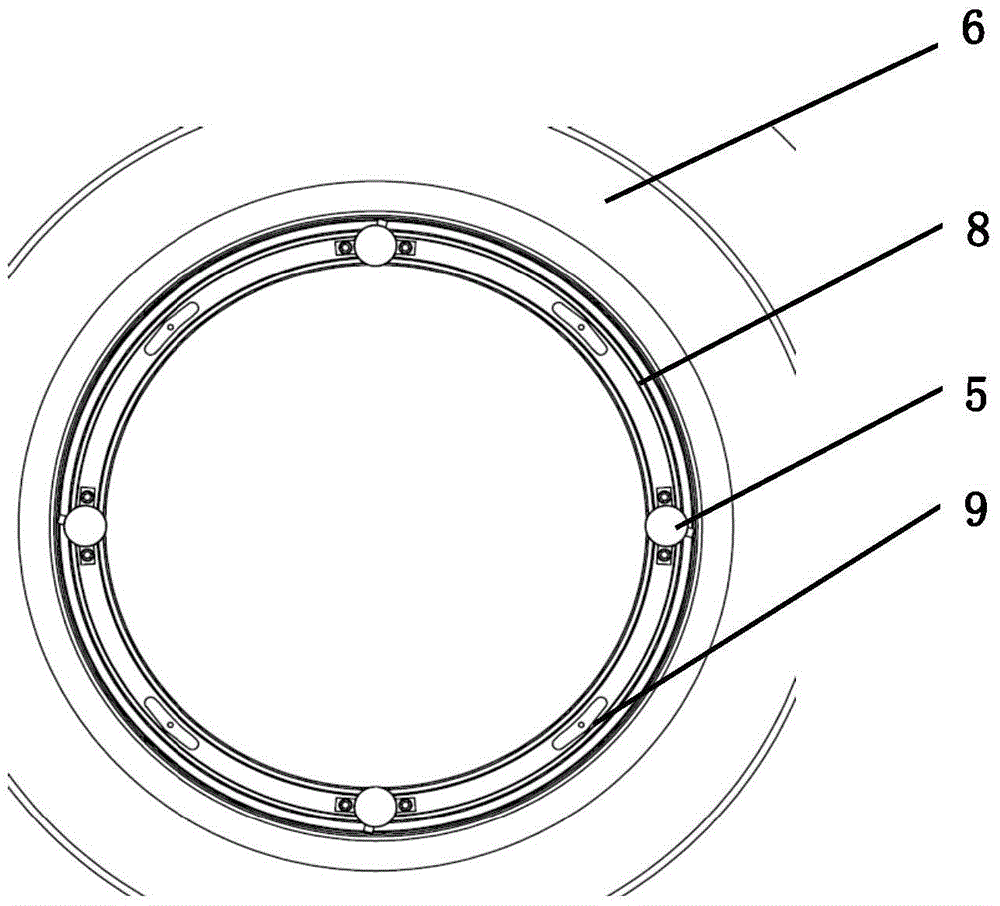

[0053] 320-ton heavy-duty truck with 6 wheels in total. The diameter of the rim is 63". The integrated gear seat 4 evenly distributes 8 oil cylinder installation holes 5. The oil cylinder installation holes 5 correspond to the position of the tire bell 7 of the tire 6, and each oil cylinder installation hole 5 is matched with a group of hydraulic dismounting devices. The upper part of the oil cylinder installation hole 5 is provided with a hydraulic cylinder 1, the piston of the hydraulic cylinder 1 is connected with the cylinder ejector rod 2, and the end of the oil cylinder ejector rod 2 is connected with the T-shaped garden post push plate 3. When the tire is removed, the hydraulic cylinder 1 works, The piston rod of the hydraulic cylinder pushes the cylinder push rod 2 and the T-shaped column push plate 3, and the T-shaped column push plate 3 pushes the tire bell 7, which reacts on the integrated gear seat 4, and the integrated gear seat 4 is separated from the tire bell 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com