Passenger car engine suspension device

An engine mount and engine technology, which is applied in the power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of unstable engine mount structure, large vibration of the whole passenger car, poor vibration isolation effect, etc. The structure is stable, the comfort is improved, and the vibration isolation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

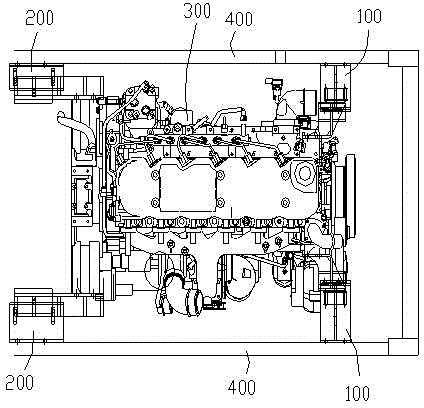

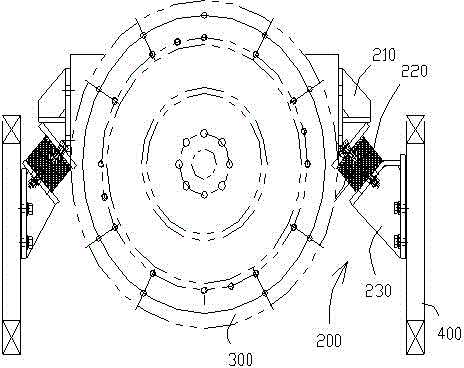

[0034] Such as figure 1 As shown, the passenger car engine suspension device adopts four-point support, including a pair of front suspension structures 100 and a pair of rear suspension structures 200, and the front suspension structures and rear suspension structures are symmetrically arranged on the left and right sides. on the frame rails. The front and rear suspension structures are all arranged at an angle of 40-50° to the plane direction where the left and right frame longitudinal beams are located, which can simultaneously isolate the vibration of the engine in six directions: up and down, left and right, and front and rear.

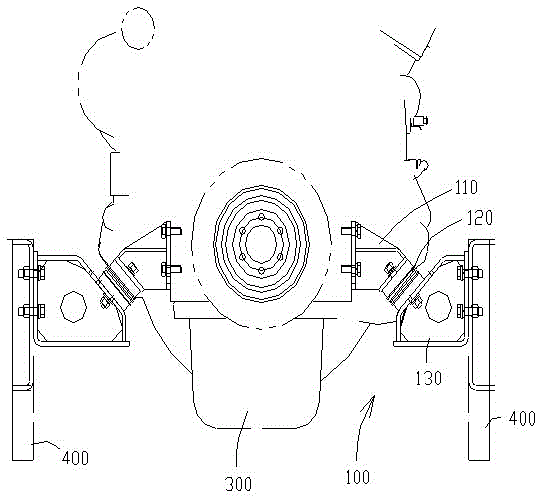

[0035] Such as figure 2 As shown, the front suspension structure 100 includes a front suspension bracket 110, a front suspension cushion 120 and a front bracket 130, the front suspension bracket is used for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com