Silencing and anti-freezing method and device for sewer line

An antifreeze device and pipeline technology, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, pipe components, etc., can solve the problems of reducing the impact force of sewage, increasing the volume, sudden noise, etc. The structure is scientific, reasonable and advanced, and the effect of eliminating noise leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

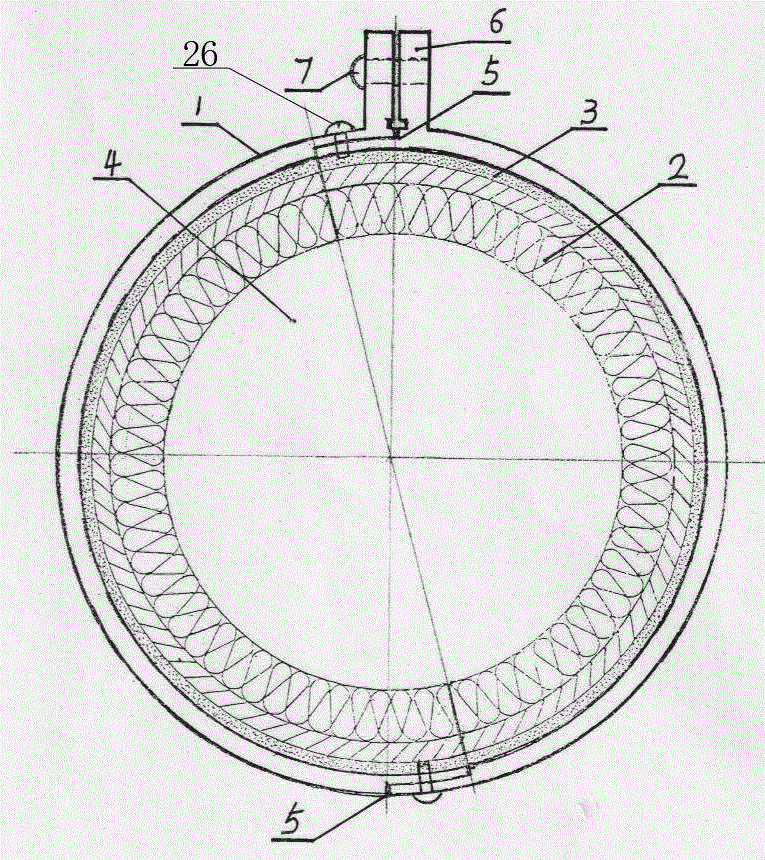

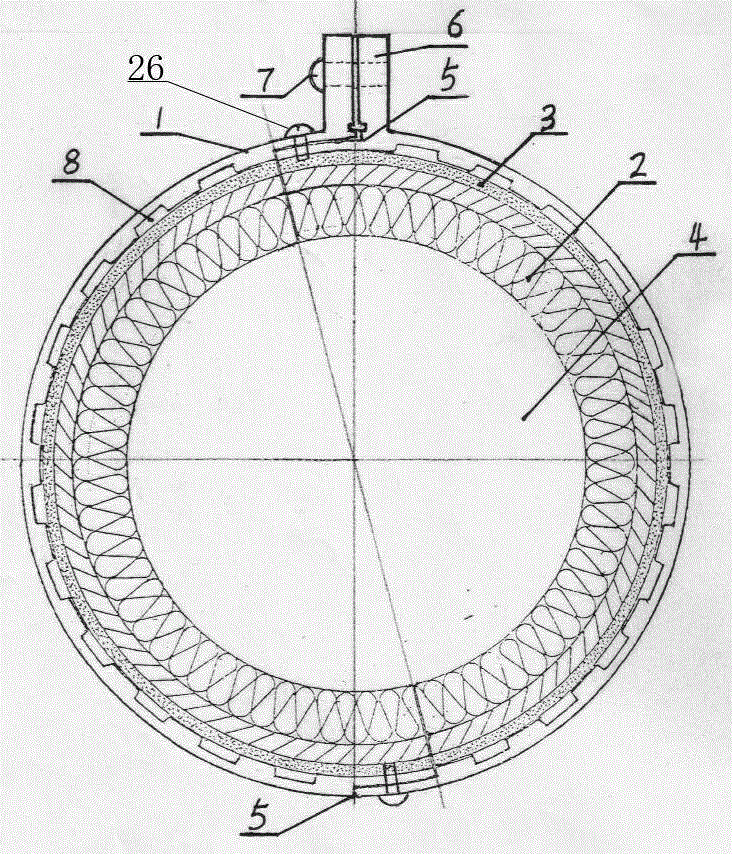

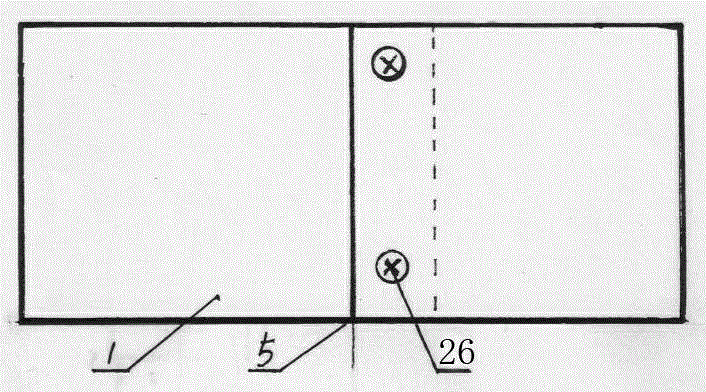

[0064] A noise reduction and antifreeze device for sewer pipes, which includes a sealed shell, noise reduction materials, and sound insulation materials; the structure is: a cavity 4 matching the outer diameter of the pipeline is left in the center, and a multi-layer structure surrounds the cavity as the center. The thick-walled pipe body; the surrounding body of the multi-layer structure is that, from the inside to the outside, it surrounds the sound-absorbing material layer 2, the sound-insulating material layer 3, and the sealed shell 1. At least one layer is the sound-absorbing material layer; the innermost layer of the sound-absorbing material layer The outermost layer is a sealed shell; the surrounding body of the multi-layer structure is composed of more than two parts of the surrounding body, and the connection mode of the two parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com