A drilling position measuring fixture

A technology for measuring fixtures and drilling positions, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as lack of measurement, unified, simple and accurate measurement methods, and difficult measurement, so as to achieve simple measurement, uniform distance, The effect of reducing the experimental measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

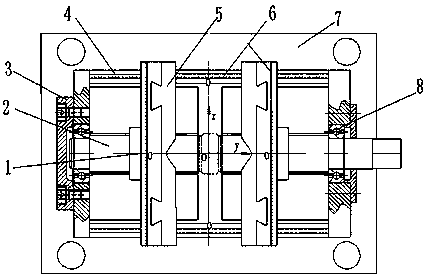

[0015] Before performing the drilling torque measurement test, firstly, the center of the fixture coordinate system is positioned to the center of the dynamometer, and the fixture is fixed on the dynamometer with bolts.

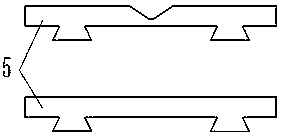

[0016] Second, determine the shape of the workpiece material, select the clamping body 5 according to the shape, and insert the clamping body 5 onto the slider.

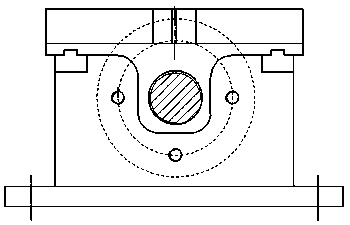

[0017] Thirdly, place the test piece on the horizontal plate in the middle of the fixture, and clamp the workpiece by turning the two-way screw.

[0018] Fourth, when positioning the tool, use the scale 6 on the fixture to determine the position of the drilling center axis in the fixture coordinate system (that is, the coordinate value (x0, y0)).

[0019] Finally, the length of each force arm is obtained by calculation: for circular workpiece materials, the center of the test piece coincides with the center of the fixture coordinate system due to the automatic shaping function of the fixture; , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com