Data transmission plate of terminal and preparation process thereof

A technology for data transmission and terminal strips, which is applied to the components of connection devices, the assembly/disassembly of contacts, electrical components, etc. The problem of high prices, etc., achieves the effect of saving mold costs and human resources, saving material resources, manpower and materials, and saving cost resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

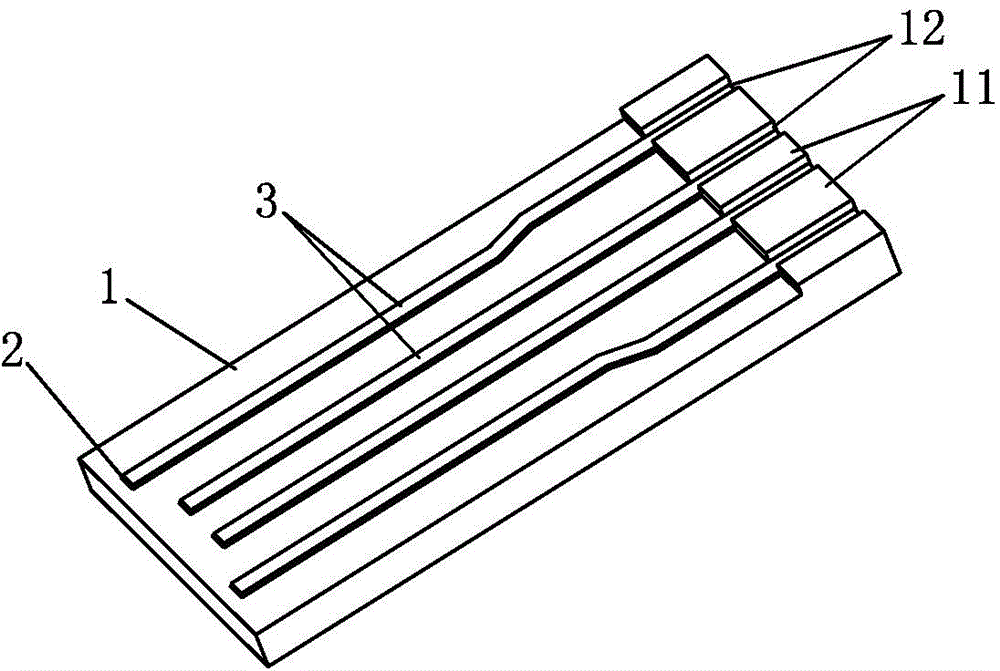

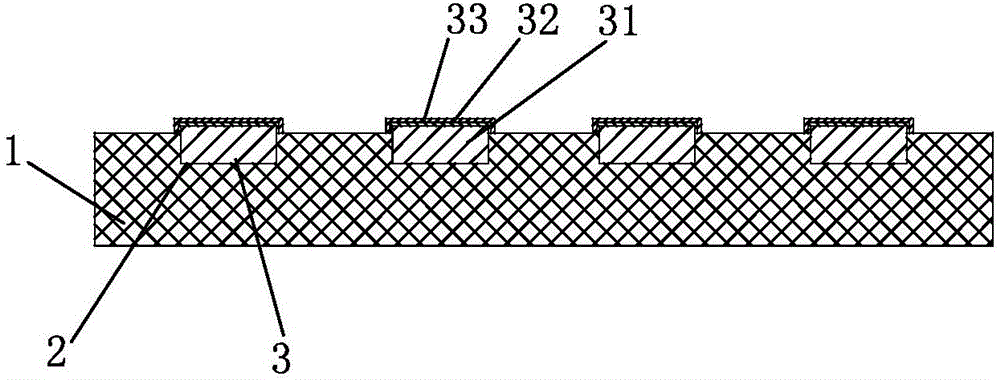

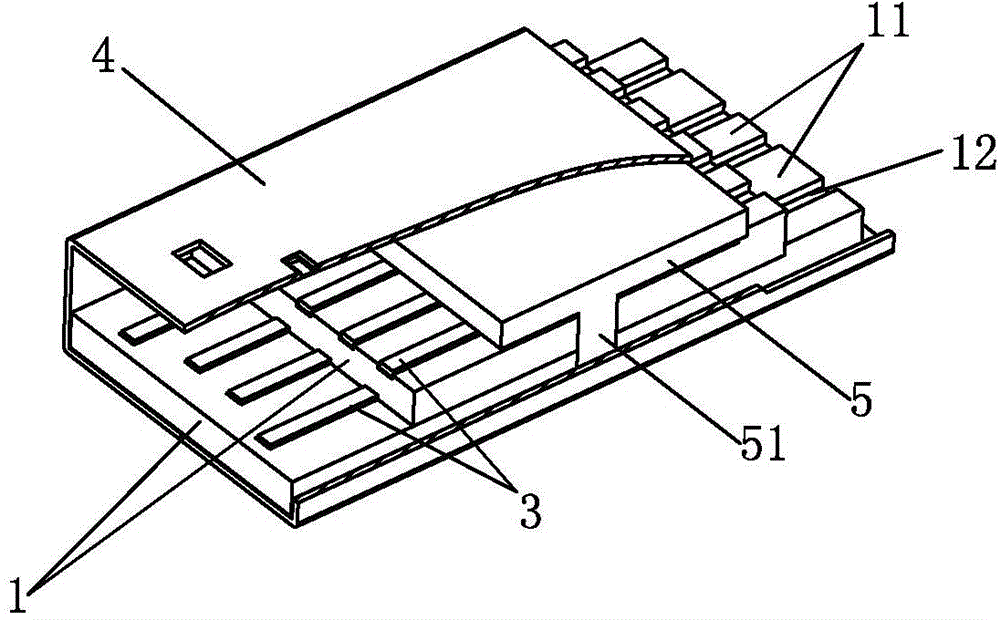

[0033] Attached below Figure 1-10 The present invention is described further:

[0034] A terminal data transmission sheet, the data transmission sheet includes an insulating body 1 of LDS material, and a plurality of depressed terminal strip grooves 2 are arranged on the insulating body 1, and electroplating terminal strips 3 are tightly embedded in the terminal strip grooves 2, and the The thickness of the electroplating terminal piece 3 is 0.05-0.6mm.

[0035] The electroplating terminal strip 3 of the present invention does not need to be positioned on the PCB board. In order to better directly connect the data line, the terminal strip groove 2 and the electroplating terminal strip 3 can be scattered and arranged at the rear end of the insulating body 1 to form a data line connection end; of course According to the size of the rear end of the insulating body 1, the data line connection ends are arranged in a reasonable layout, and the electroplating terminal strips 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com