Light foldable high-voltage switch trolley guide rail for transformer station, and use method

A high-voltage switch, trolley guide rail technology, applied in pull-out switch cabinets, switchgear, electrical components, etc., can solve the problems of loss of monitoring, heavy high-voltage switch trolley, no positioning block, etc., to avoid operation accidents and shorten operation time. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

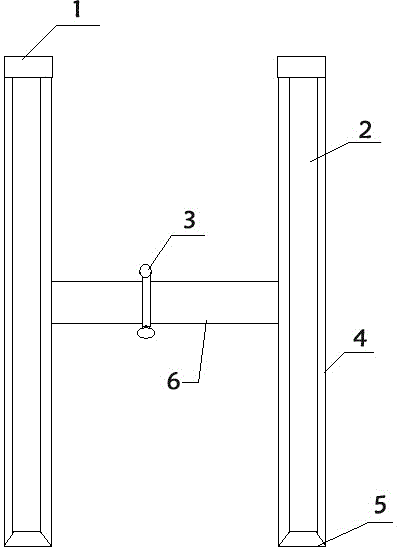

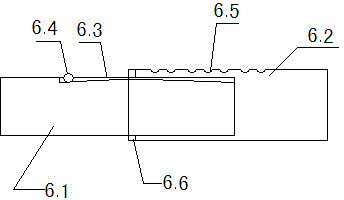

[0017] combined with Figure 1-3 , to further describe the present invention:

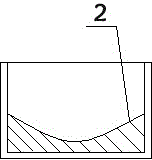

[0018] The present invention includes a positioning block 1, a guide rail 2, a folding shaft 3, a guide rail base 4, a buffer groove 5, and a support plate 6. Two parallel guide rail bases 4 are connected through the support plate 6. The guide rail base 4 is provided with a guide rail 2, One end of the guide rail base 4 is provided with a positioning block 1, the other end of the guide rail base 4 is provided with a buffer groove 5, and the support plate 6 is provided with a folding shaft 3; wherein, the support plate 6 includes a first support plate 6.1, a second support plate 6. The support plate 6.2, the first support plate 6.1, and the second support plate 6.2 are plugged together, the inside of the first support plate 6.1 is provided with an outer arc-shaped steel bar 6.3, and the non-arc-shaped steel bar 6.3 is provided with a semicircular groove. A ball 6.4 is provided in the semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com