Anti-corrosion structure of motor bearing and plastic-encapsulated brushless DC motor

A motor bearing and anti-motor technology, which is applied in the direction of casing/housing/support, electromechanical devices, electrical components, etc., can solve the problems of bearing corrosion and low manufacturing cost of anti-electrical corrosion structure of motor bearings, so as to prevent electric corrosion, The effect of ensuring the service life and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

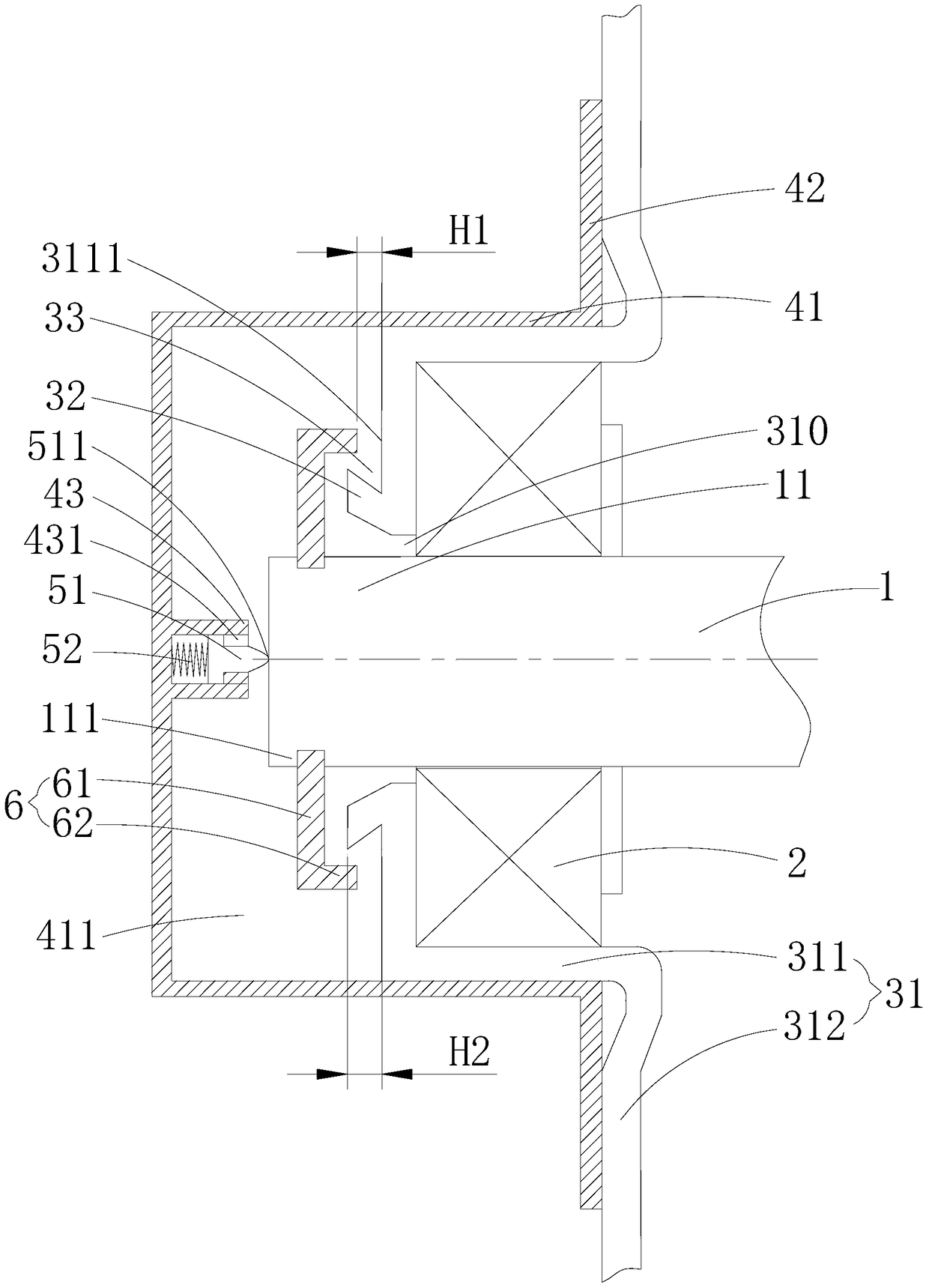

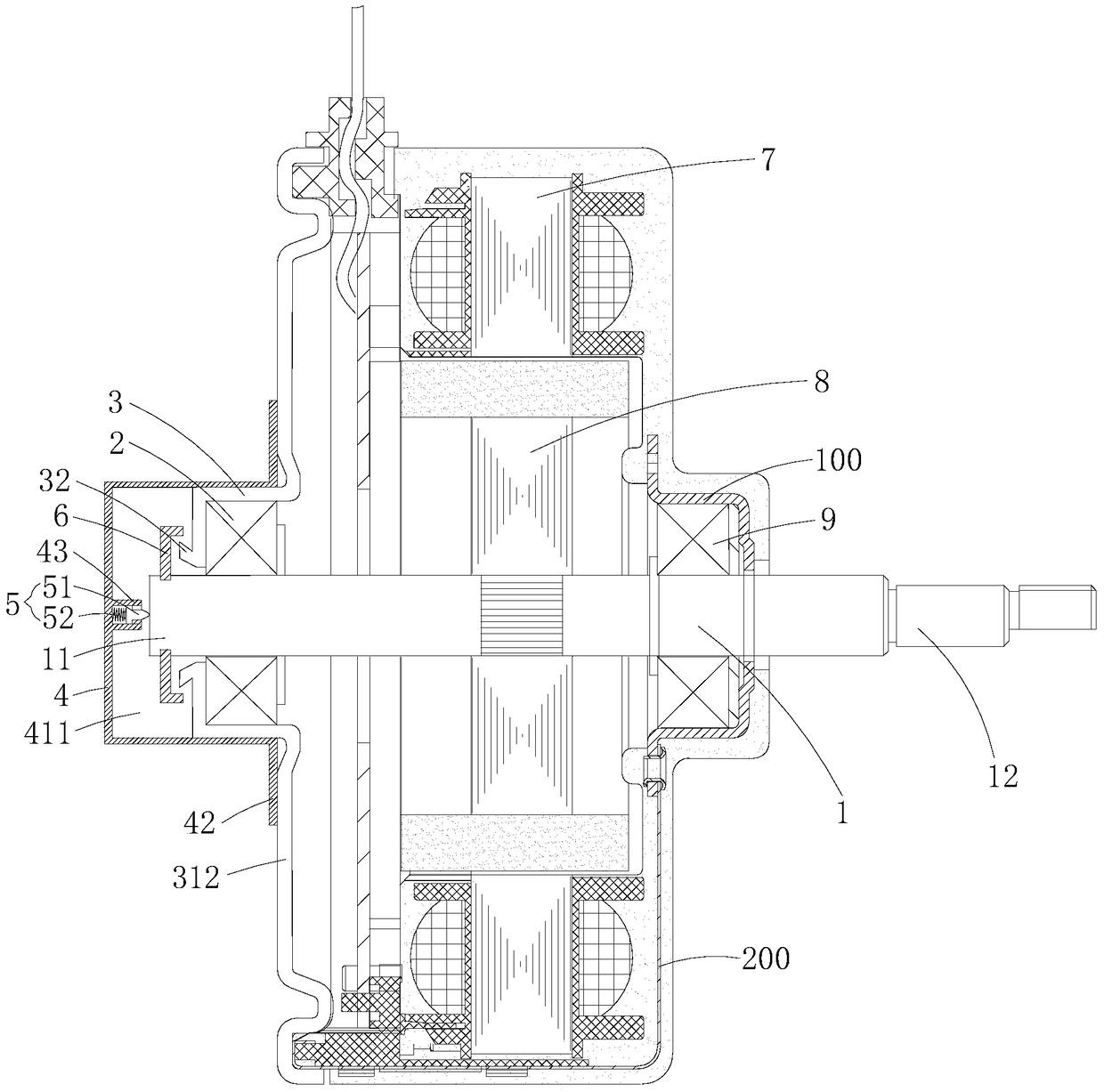

[0024]Specifically, since the conductive slider 51 is used to electrically connect the conductive casing 4 and the rotating shaft 1 , there should be conductive connections between the conductive slider 51 and the conductive casing 4 , and between the conductive slider 51 and the rotating shaft 1 . In this embodiment, the conductive connection between the conductive slider 51 and the rotating shaft 1 is realized by the direct abutting contact between the conductive slider 51 and the extension part 11, and the conductive connection between the conductive slider 51 and the conductive casing 4 There are several specific implementation methods as follows: the conductive slider 51 can realize direct conductive connection with the conductive casing 4 through direct contact with the conductive casing 4; housing 4; or, the conductive slider 51 can also be directly conductively connected to the conductive housing 4 and indirectly conductively connected to the conductive housing 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com