Electron beam welding machine power supply high-voltage voltage stabilization method and method employing micro ripper Cuk type converter

A technology of electron beam welding and converter, which is applied in the direction of output power conversion device, DC power input conversion to DC power output, instruments, etc., which can solve the problems of poor operability, increased volume of switching power supply, poor integration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

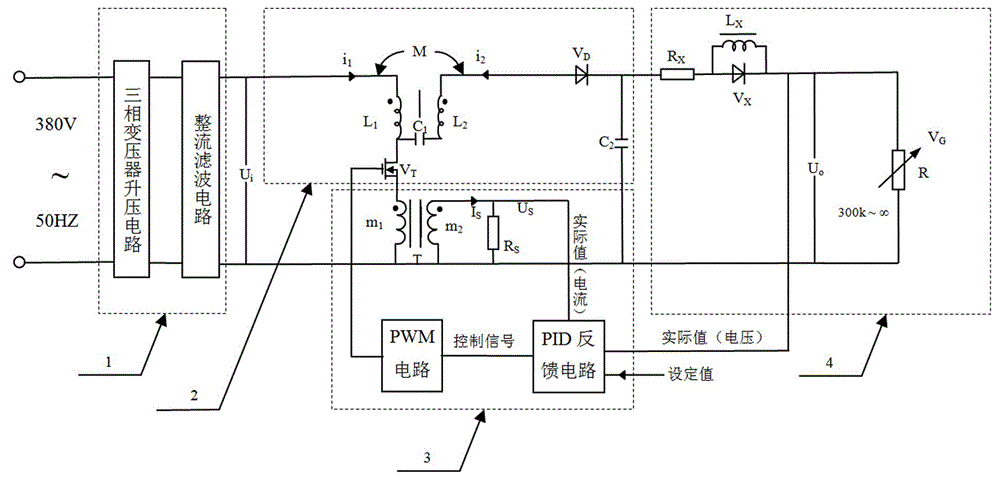

[0056] A method for stabilizing the high-voltage voltage of an electron beam welding machine power supply using a micro-ripple Cuk type converter, comprising the steps of:

[0057] 1) After the three-phase AC power supply is boosted, rectified and filtered, a high voltage voltage is obtained;

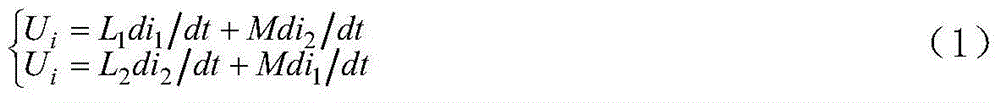

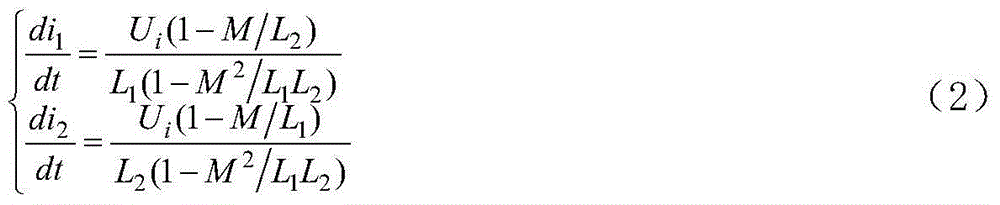

[0058] 2) The high-voltage voltage passes through the DC converter, and the output voltage is adjusted by controlling the on-off duty cycle of the switching device;

[0059] 3) The output voltage is fed back through the voltage outer loop and current inner loop of the Proportional-Integral-Differential Controller (PID), and compared with the set value, and the voltage of the error obtained by comparison (whether written in this way Correct) After a pulse width modulation (Pulse Width Modulation, PWM for short) circuit, the output voltage can be adjusted by controlling the duty cycle of the power device;

[0060] 4) Obtain a high-voltage regulated output voltage with minimal ripple at t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap