Roller shutter with door leaf in the form of a flexible curtain

A rolling gate and door leaf technology, which is applied in the field of rolling gates, can solve problems such as product damage and personnel injury, and achieve the effect of not being easily damaged, reducing the risk of damage, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

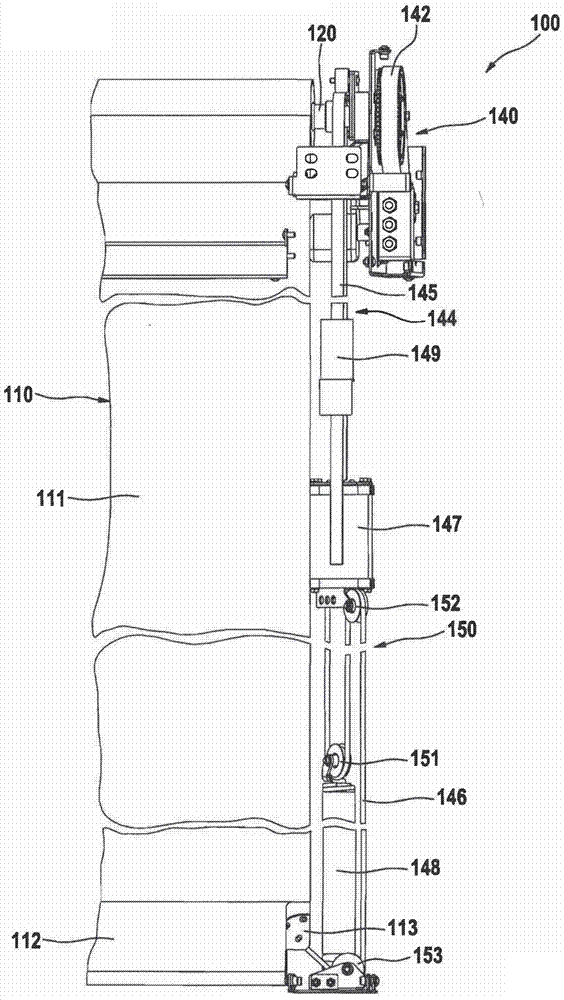

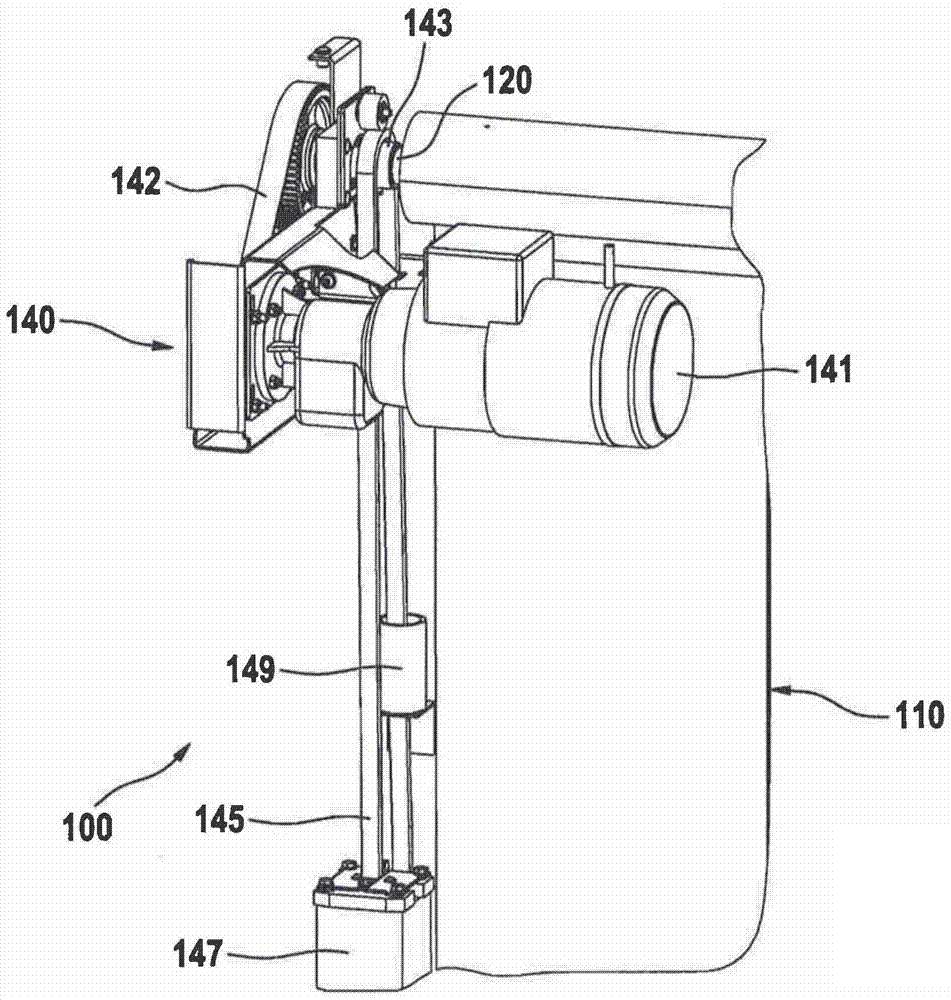

[0053] Figures 1 to 4 A first exemplary embodiment of a rolling shutter 100 is shown.

[0054] It comprises a door leaf 110 substantially consisting of a flexible curtain with a curtain part 111 and a terminating element 112 arranged on its forward edge. A forward edge is an edge region and / or edge located on the curtain part 111 which is located forward in the direction of movement during closing of the door leaf 110 .

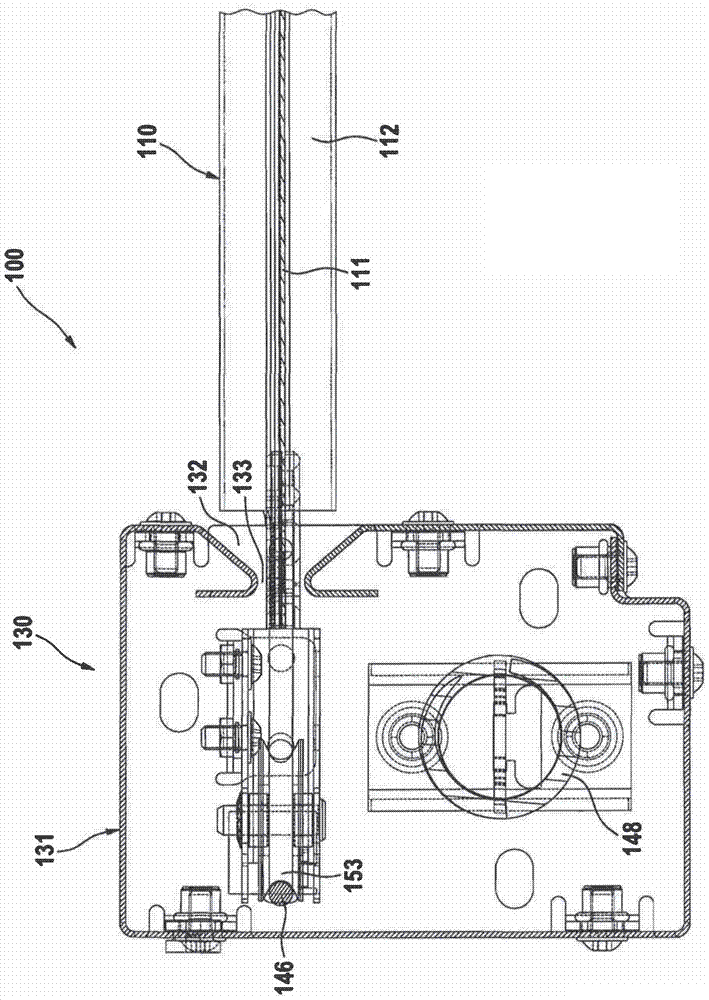

[0055] In the present case, the rolling gate 100 , which is designed as a lift gate, also comprises a reel 120 on which the door leaf 110 is wound during the opening of the rolling gate 100 . Additionally, the rolling gate 100 includes side guides 130, one of which is shown in figure 2 , and it accommodates the side edges of the door leaf 110 . Finally, the rolling shutter 100 comprises a drive 140 which generates a driving force for driving the door leaf 110 .

[0056] figure 2 is a cross-sectional plan view of one of the side guides 130 . As can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com