Insulating body having integrated shield element

一种屏蔽元件、绝缘体的技术,应用在电气元件、连接装置的零部件、固定/绝缘接触构件等方向,能够解决压接环易打滑、插入式连接器封装耗时等问题,达到快封装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

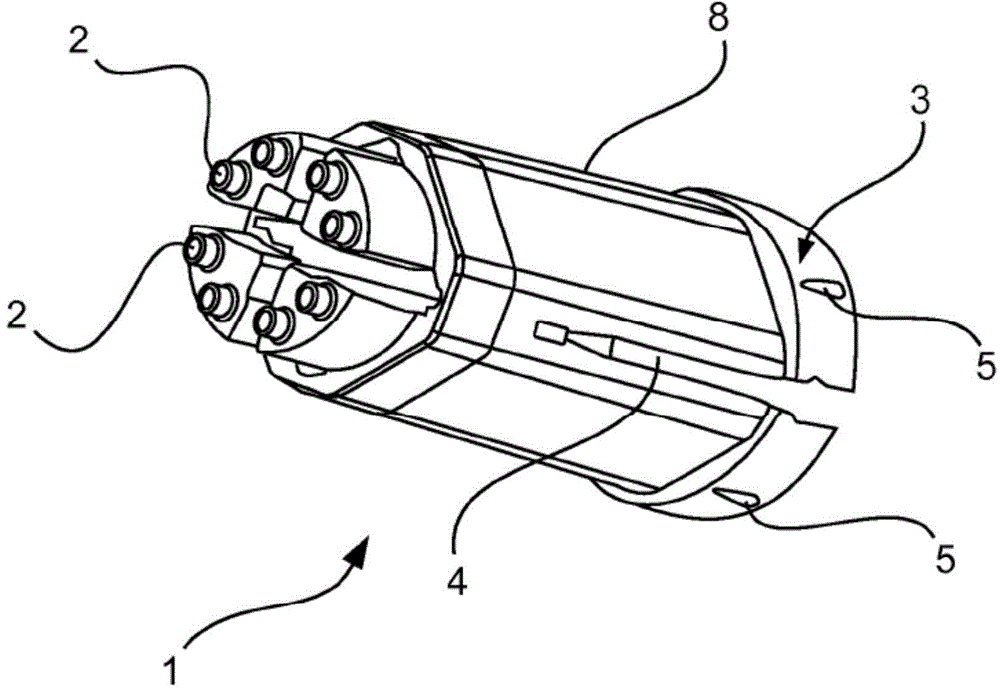

[0029] figure 1 A possible embodiment of the insulator according to the invention is shown. The insulator 1 basically has the shape of a hollow cylinder, with holes 2 on the insertion-side end face, through which contact elements (not shown) protrude. On the connection side, the insulator 1 has a shielding element 3 interrupted by an axially extending groove 4 . The axial groove 4 extends further beyond the shielding area in the insertion direction. The length of the axial slot 4 corresponds to approximately two thirds of the total length of the insulator. It has been shown that this slot length is particularly suitable for the packaging of plug-in connectors.

[0030] As already indicated above, the insulator 1 is formed from a plastic body which is partially coated with metal using the MID method, and this metal-coated part forms the shielding element 3 .

[0031] On the outer periphery of the shielding element 3 a clamping device 5 is molded, the function of which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com