dishwasher drying system

A drying system, dishwasher technology, applied in the direction of tableware washing machine/rinsing and washing machine parts, etc., can solve the problems affecting the dishwasher, electrical safety and reliability, etc., achieve low cost of improvement, and avoid the impact of water flow function , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

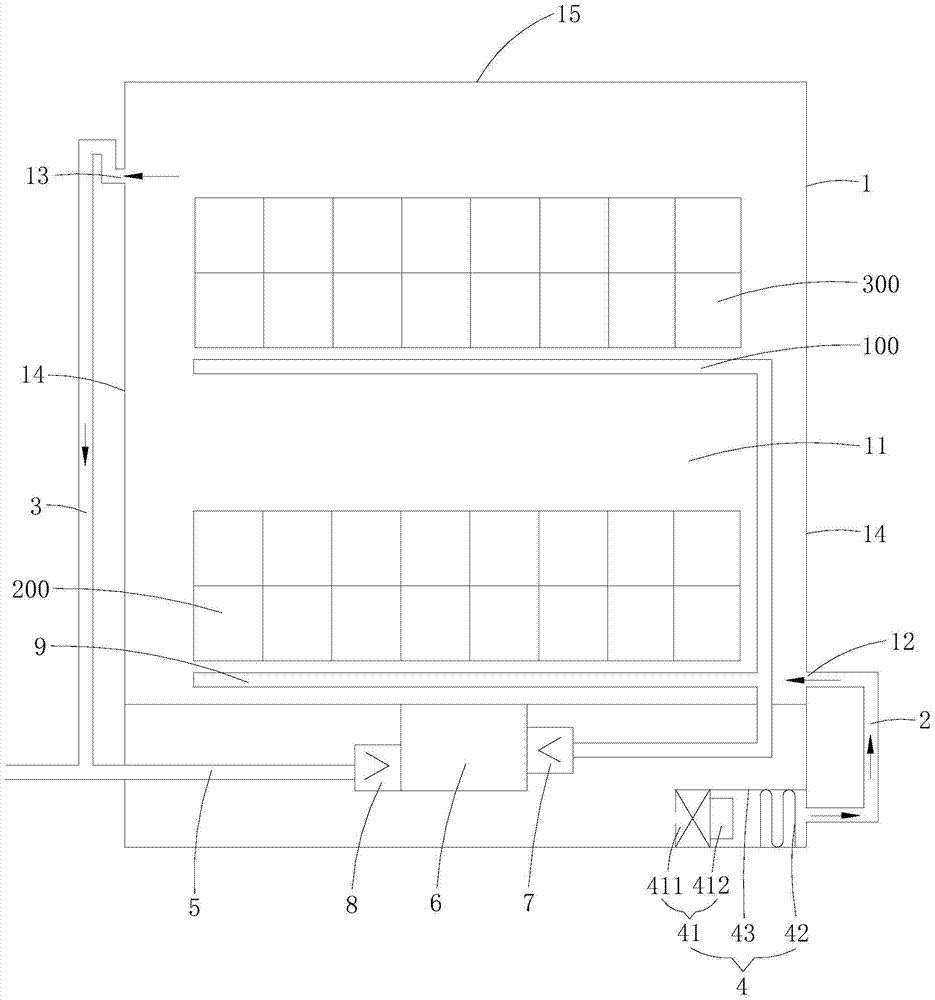

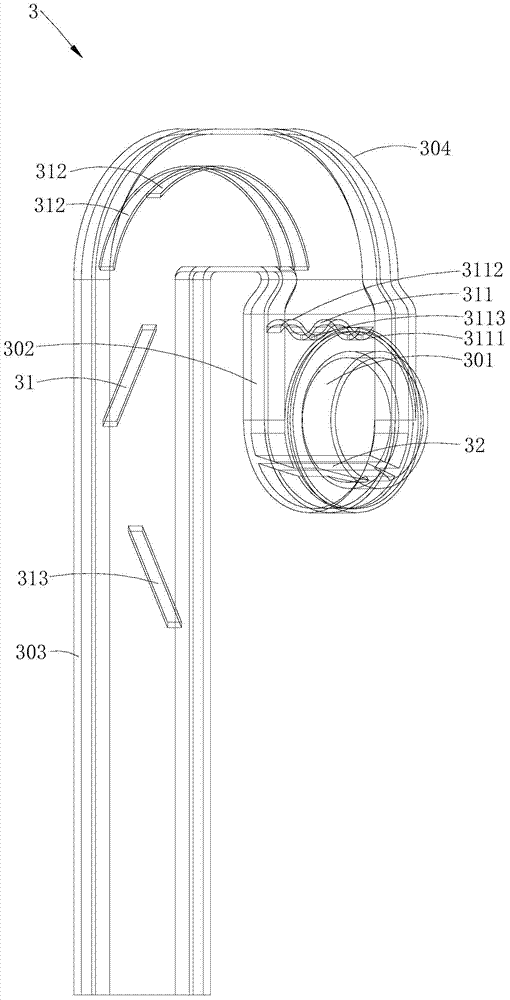

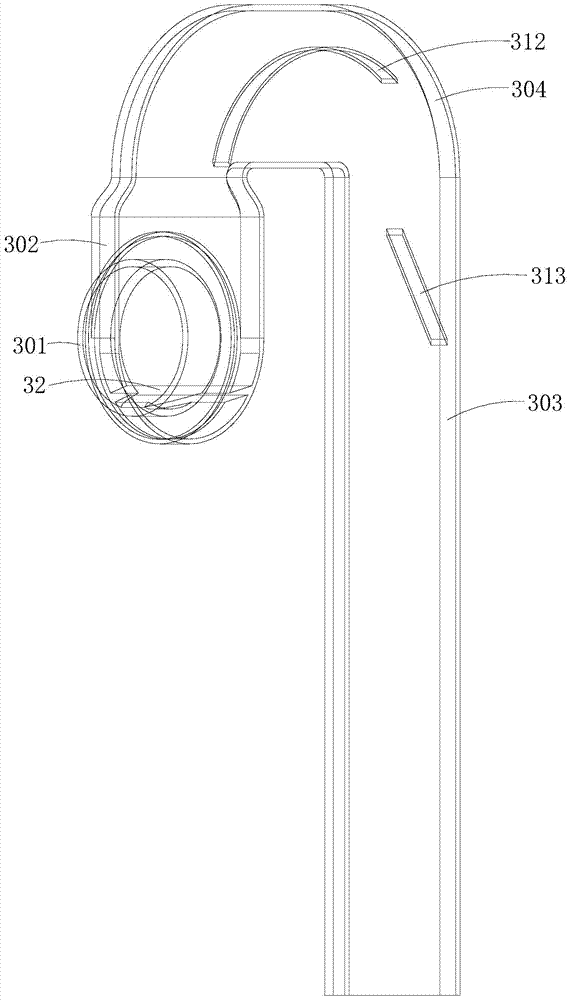

[0028] Such as Figure 1~4 As shown, the dishwasher drying system provided by Embodiment 1 of the present invention includes an inner container 1, an air inlet pipe 2, an air outlet pipe 3, a blowing device 4 and a drain pipe 5. The inner container 1 has an inner cavity 11, and an inner cavity The air inlet 12 communicated with 11 and the air outlet 13 communicated with the inner cavity 11, the air inlet 12 is connected to the blowing device 4 through the air inlet pipe 2, and the air outlet 13 is connected to the drain pipe 5 through the air outlet pipe 3. The dishwasher drying system provided in this embodiment connects the air inlet 12 and the blowing device 4 through the air inlet pipe 2, so that the blowing device 4 can blow air into the inner tank 1, thereby speeding up the discharge of hot and humid air from the inner tank 1 , Improve the drying efficiency of tableware. At the same time, it connects the air outlet 13 and the drain pipe 5 through the air outlet pipe 3, ...

Embodiment 2

[0045] Such as Figure 5 As shown, the dishwasher drying system provided in this embodiment differs from the first embodiment mainly in that the positions of the air inlet 12 , the air outlet 13 , and the blowing device 4 are different. Specifically, in this embodiment, the air inlet 12 is arranged near the top of the inner container 1, the blowing device 4 is installed above the inner container 1, the air outlet 13 is arranged near the bottom of the inner container 1, and the air inlet 12 and the air outlet 13 are respectively It runs through two opposite side panels 14 of the inner container 1 . The working principle of the dishwasher drying system provided in this embodiment is: the blowing device 4 continuously blows dry hot air into the inner container 1, and the dry hot air generated by the blowing device 4 enters the inner container 1 from the top of the inner cavity 11 The hot and dry air entering the inner cavity 11 will fully contact and mix with the hot and humid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com