Trolley conductor structure for increasing IP protection grade

A technology of sliding contact line structure and protection level is applied in the field of construction elevators, which can solve the problems of insufficient electrical safety and reliability, unsatisfactory use effect, and low protection level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

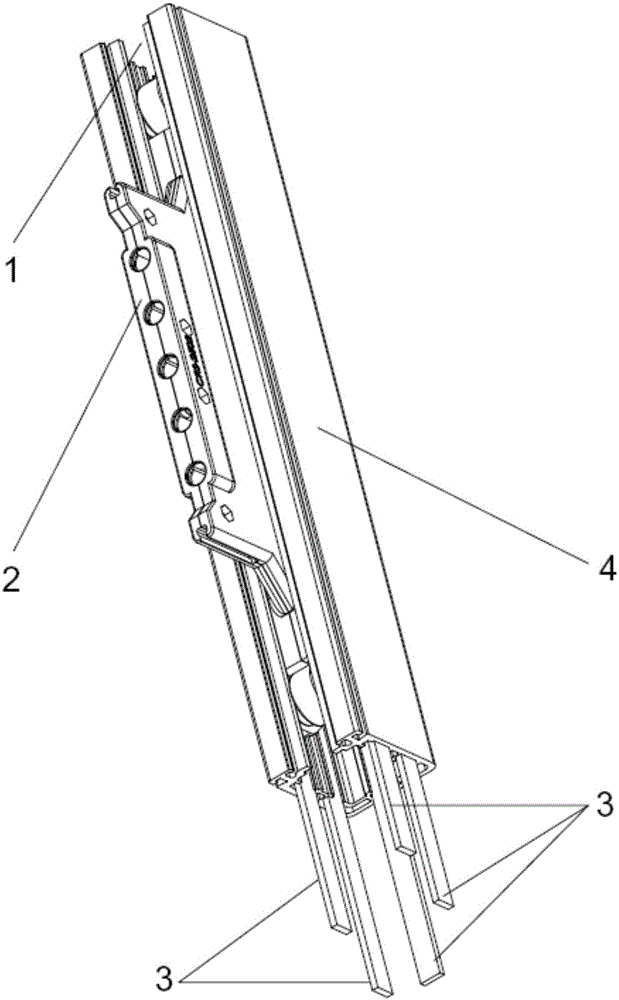

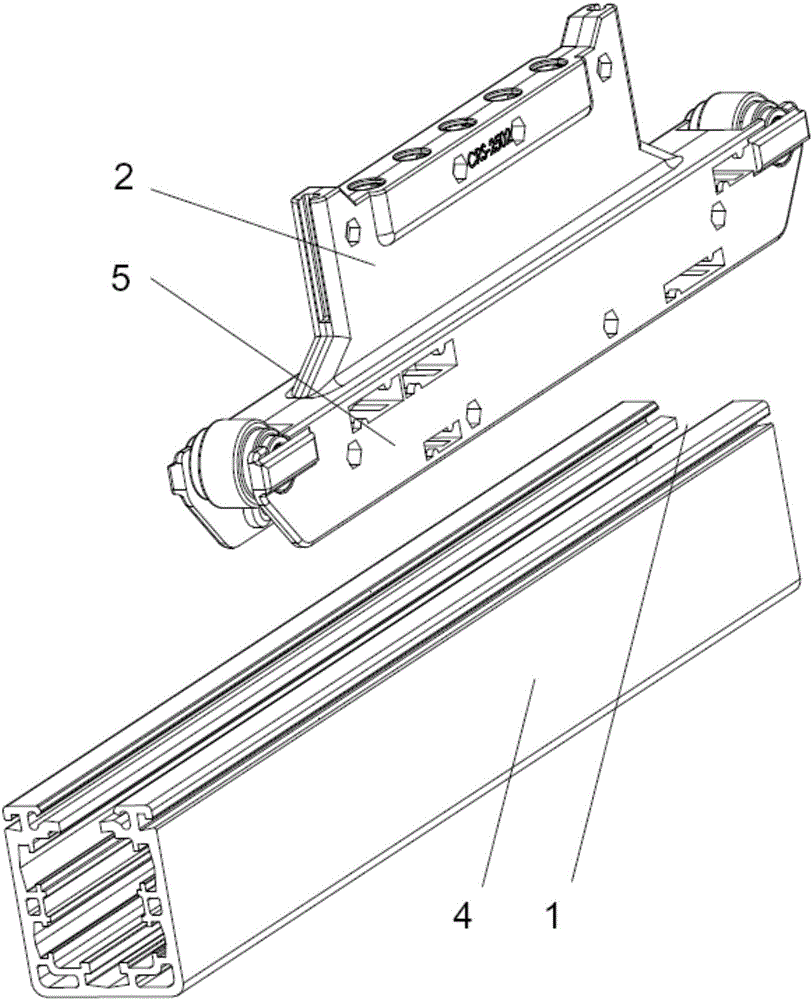

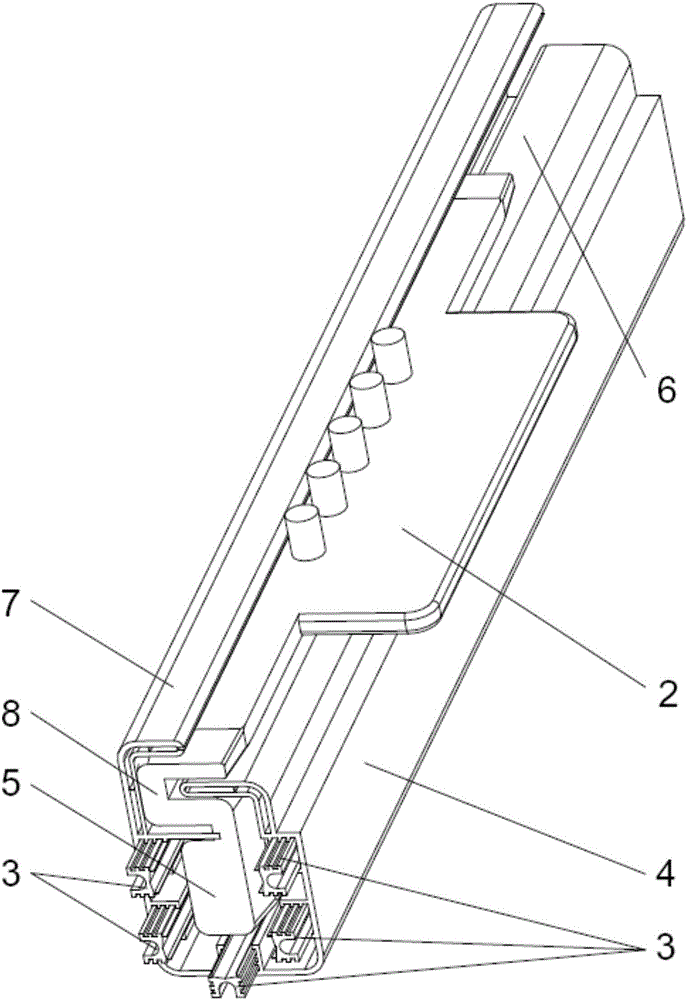

[0017] Embodiments of the present invention, such as image 3 , Figure 4 shown. A sliding contact wire structure with improved IP protection level, comprising a square tube-shaped wire sleeve 4 with a long straight opening on the top surface of the sleeve body, and a collector that is movably connected to the wire sleeve 4; the inner wall of the wire sleeve 4 Slots are provided on the left, right, and bottom sides of the motor, and corresponding conductive strips 3 are inserted into the slots; the collector includes a square box-shaped brush box 5 set in a wire sleeve 4, and a flat rectangular box-shaped wiring Box 2; the bottom of the junction box 2 is connected to the top of the brush box 5, and the top of the junction box 2 protrudes from the cover opening 1; the left and right sides of the top surface of the wire cover 4 are respectively provided with angle steel-shaped B bends Type 7, first bending type 6; the horizontal folds of the two bending types are opposite to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com