Separation type phase change heat dissipation inversion device

An inverter device, a separate technology, applied in the field of separate phase-change heat dissipation inverter devices, can solve the problems of thermal breakdown of internal power devices, troublesome installation and operation, and frozen cracked pipes, etc., achieving simple structure and low cost. The effect of low and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

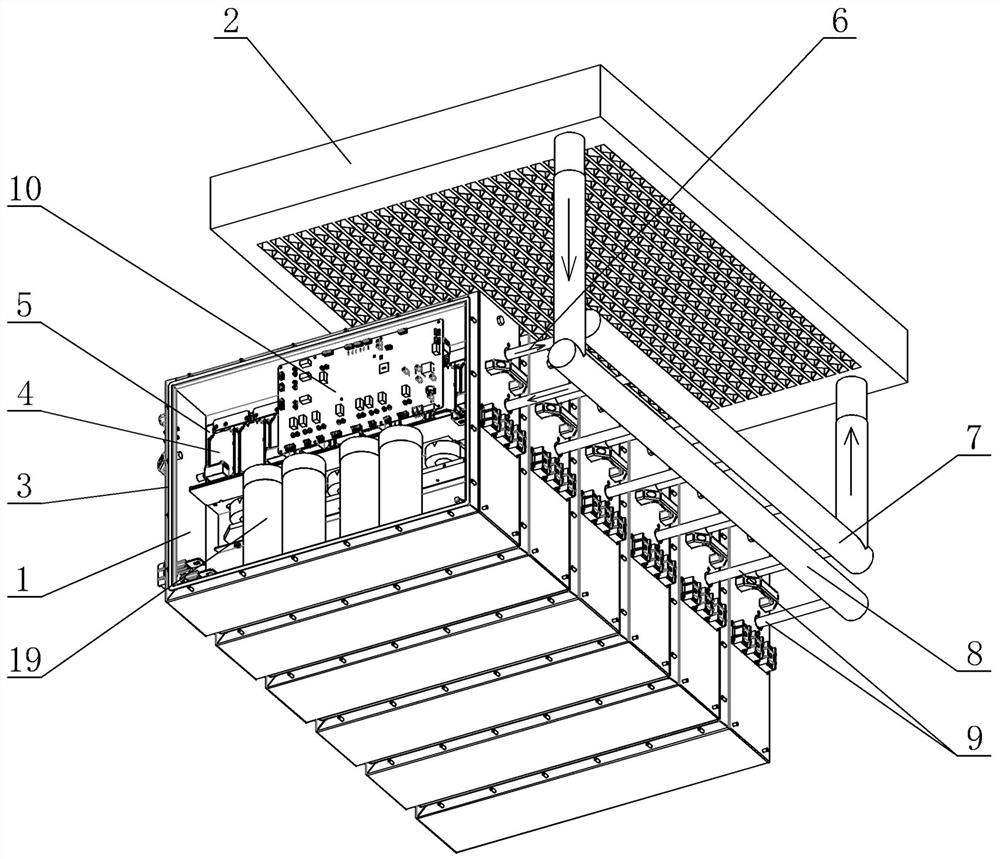

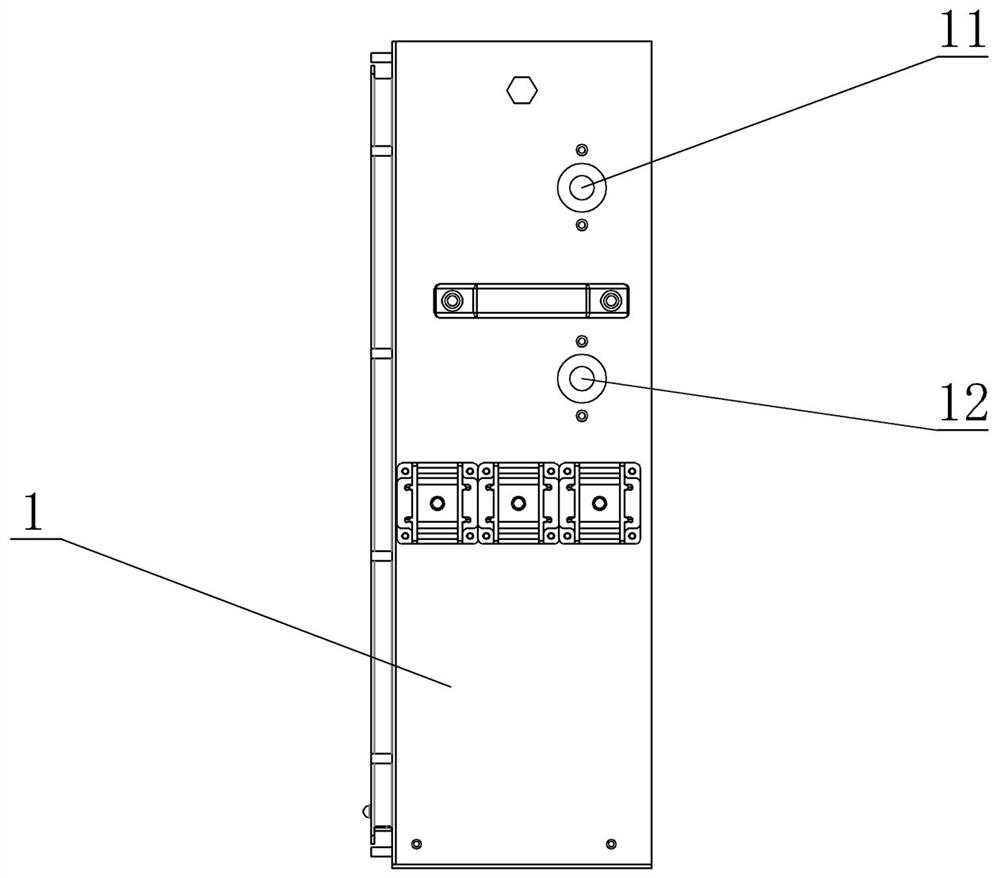

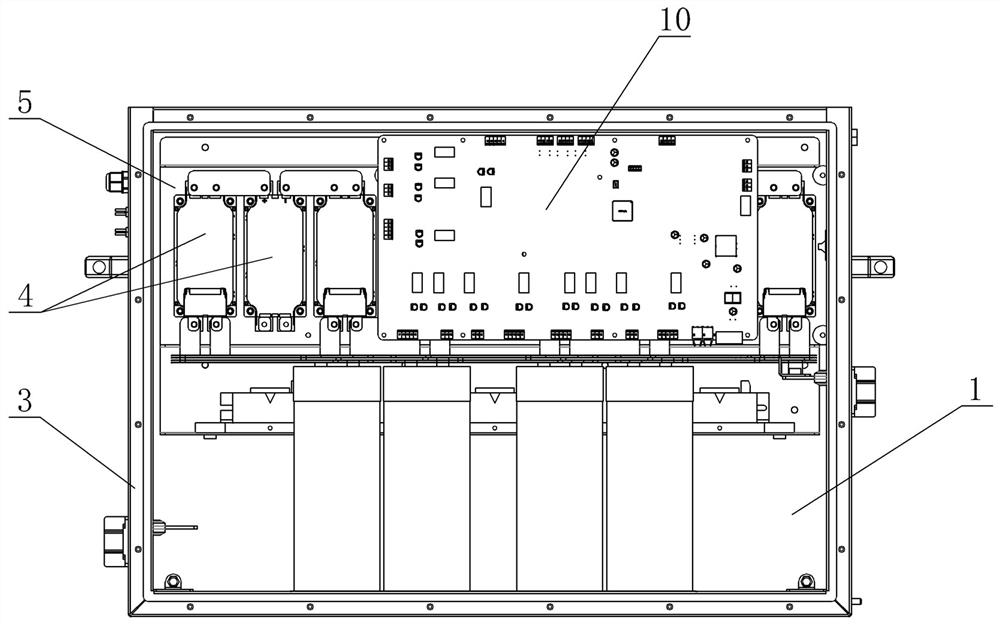

[0027] Such as figure 1 As shown, the perspective view of the inverter device of the separated phase change heat dissipation of the present invention is given, figure 2 and image 3 The front view and the left view of the power unit in the present invention are given respectively, which are composed of multiple power units 1, a heat exchanger 2, a cooling plate 5, an outflow main pipe 7, an outflow branch pipe 6, a return main pipe 8, and a return branch pipe 9 The power unit 1 is composed of a unit case 3 and a control circuit board 10 arranged in the unit case 3, an electrolytic capacitor 19 and a plurality of semiconductor power devices 4, and the semiconductor power devices 4 are reversed under the control of the control circuit board 10. change jobs. Each power unit 1 shown is provided with a cooling plate 5, and the semiconductor power device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com