a sealed structure

A technology of sealing structure and sealing strip, applied in the direction of sealing shell, engine sealing, engine components, etc., can solve problems such as affecting the sealing effect, and achieve the effect of improving production efficiency, simple operation, and avoiding height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

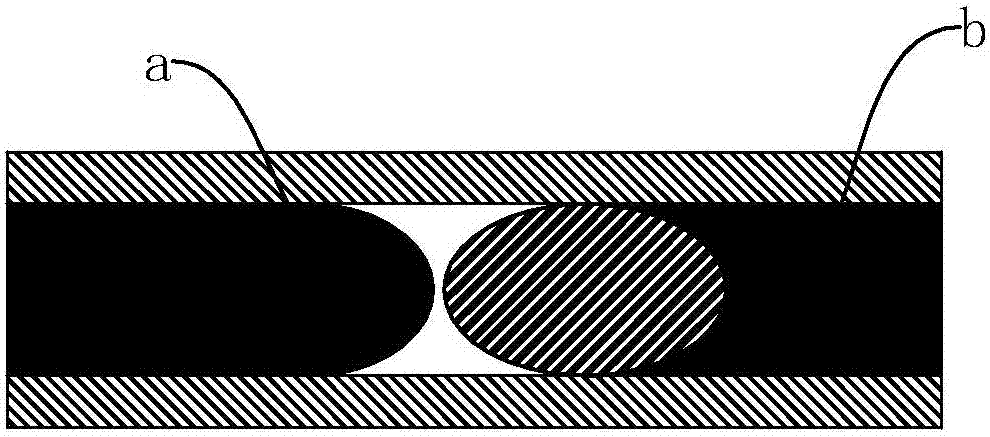

[0031] Figure 2 to Figure 6 A first preferred embodiment of the sealing structure of the present invention is shown, said sealing structure is used to install a sealing strip 3, said sealing structure comprises an upper part 1 and a lower part 2, said sealing strip 3 is arranged on said upper part 1 and the lower part 2.

[0032] The lower part 2 forms a sealing strip installation groove 21, and the sealing strip installation groove 21 has a joint area 210. The width of the joint area 210 is greater than twice the width of the sealing strip 3 and does not exceed the sealing strip 3. twice the width of the strip 3 , so that the two joints 31 , 32 of the sealing member 3 can be arranged side by side in the joint area 210 .

[0033] It is worth mentioning that the sealing strip installation groove 21 is annular, and the sealing strip 3 is straight. After the sealing strip 3 is installed in the sealing strip installation groove 21, the two sides of the sealing strip 3 The joint...

no. 2 example

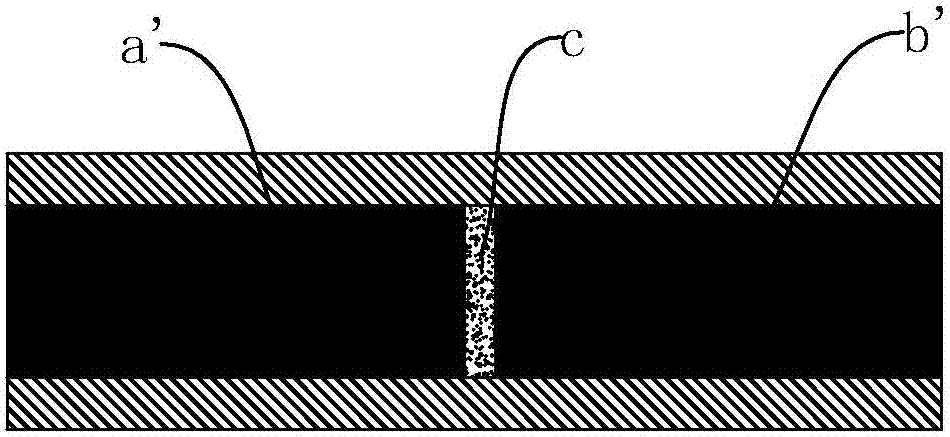

[0045] Figure 7 A modified embodiment of the present invention is shown, which is different from the first embodiment in that: the sealing strip installation groove 21 has no outlet. At this time, attention should be paid to the length of the sealing strip 3 when cutting, so as to avoid the length of the sealing strip 3 being too long, so that the joints 31 , 32 cannot be completely installed into the joint area 210 . The advantage of this embodiment is that it prevents the joints 31 and 32 from extending outside the sealing strip installation groove 21 and affecting the appearance of the product.

no. 3 example

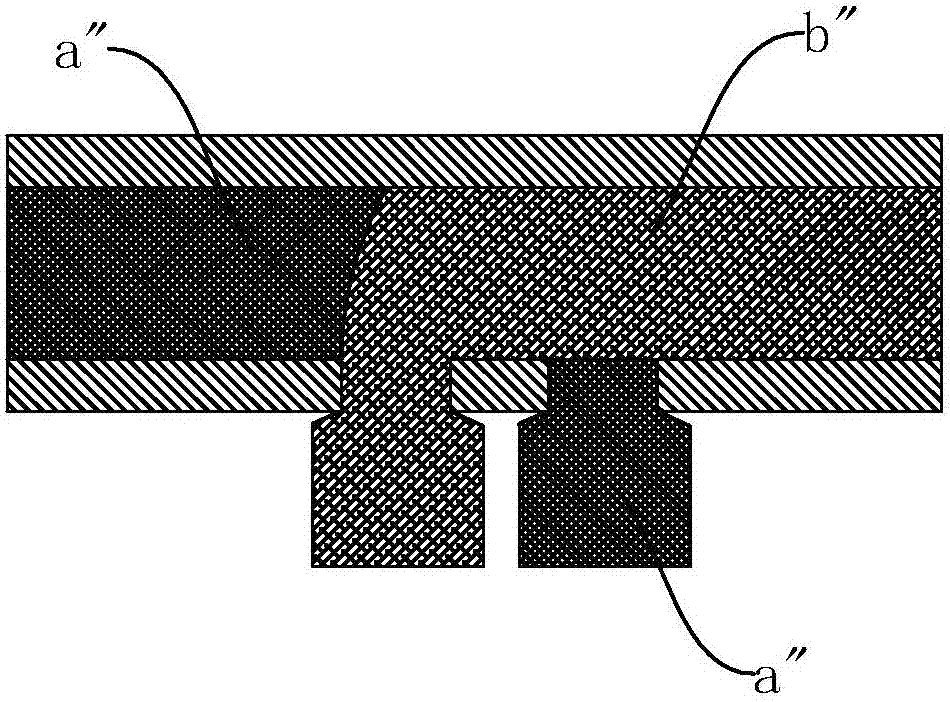

[0047] Figure 8 Another modified embodiment of the present invention is shown, which is different from the first embodiment in that: the direction of the outlet 212" is consistent with the extending direction of the sealing strip installation groove 21, so that the sealing strip 3 The connectors 31, 32 can be directly snapped into the outlet 212".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com