Laser marking method, laser marking machine and laser marking system

A laser marking method and technology of laser marking machine, applied in the field of laser marking method, laser marking machine and system, can solve the problems of inaccurate marking point, low marking resolution, small area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

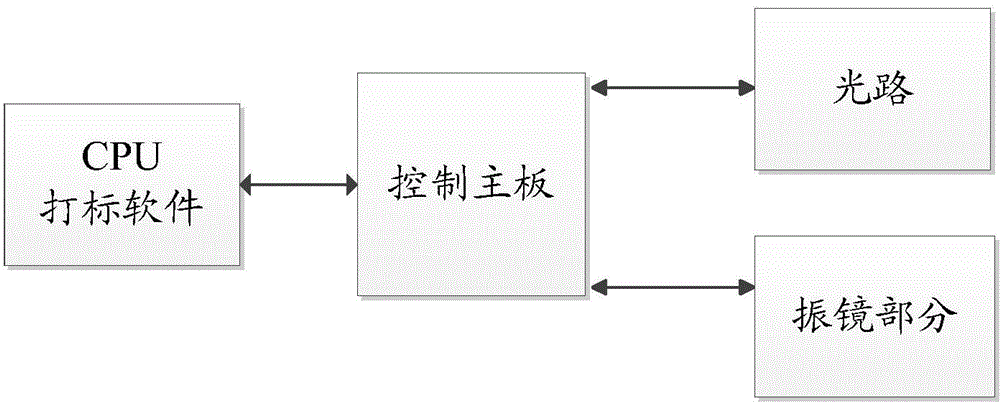

[0070] refer to figure 1 It is a structural block diagram of a general marking machine. A general marking machine includes: CPU / marking software, control board, optical path, and vibrating mirror. Among them, the CPU / marking software is mainly responsible for the processing and editing of graphics (bitmaps, vector graphics, text, two-dimensional codes, etc.), and will convert the graphics into graphics that can be recognized by the control board according to the operator's settings and marking conditions. Marking instruction, the marking instruction is the action splitting of the marking machine, and each instruction is an action of the marking machine. After the command is generated, the command is enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com