Lower film gravity pretightening device of full-automatic stretch film packer

A technology of stretching film and packaging machine, applied in the field of tensioning device, can solve problems such as affecting the synchronization rate of work, affecting production efficiency, film running deviation, etc., so as to reduce the occurrence rate of failures, improve production efficiency, and be difficult to form wrinkles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

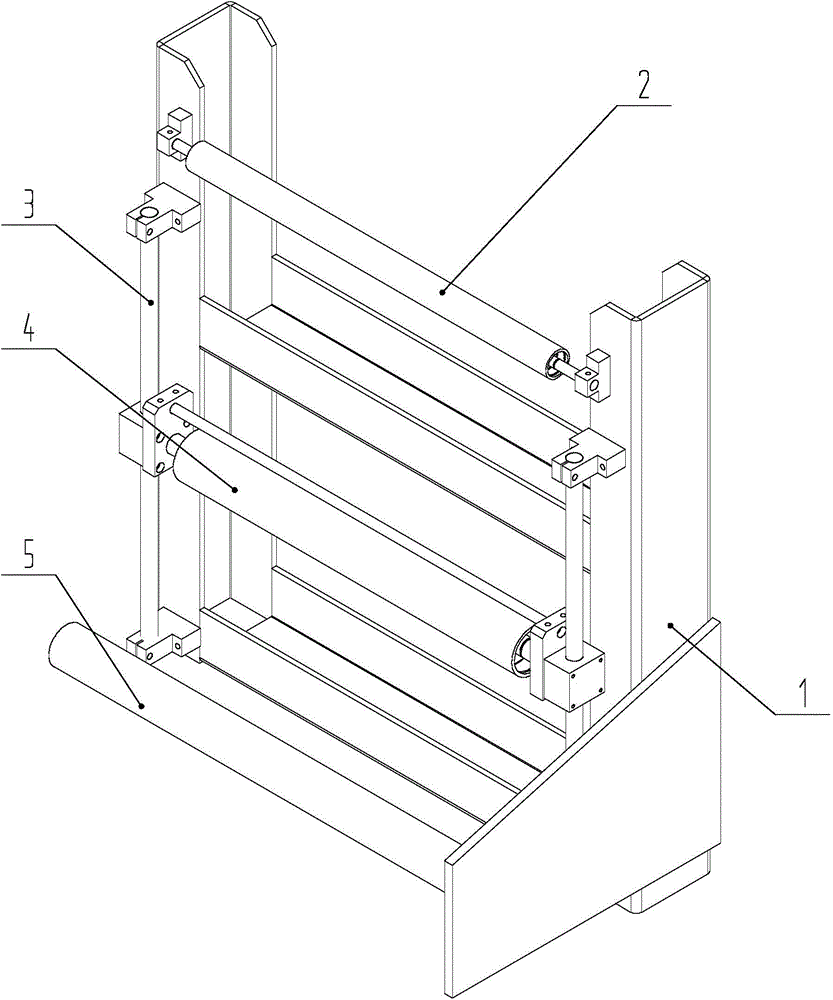

[0009] Such as figure 1 As shown, the present invention includes a frame 1, a film guide roller 2, a guide frame 3, a gravity pretensioning roller 4, and an inflatable shaft 5. It is characterized in that a film guide roller 2 is provided on the upper part of the front side of the frame 1, so A guide frame 3 is provided below the film guide roller 2, and a gravity pretension roller 4 is provided between the guide frames 3, and the guide frame 3 penetrates both ends of the gravity pretension roller 4, and the lower end of the guide frame 3 is provided with The air expansion shaft 5, the film guide roller 2, the guide frame 3, the gravity pre-tensioning roller 4, and the air expansion shaft 5 are located on the same side of the frame 1.

[0010] The working principle of the present invention: the stretched film is placed on the inflatable shaft 5, passes through the underside of the gravity pre-tensioning roller 4, and after being drawn out by the film guide roller 2, the stretched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com