A pole piece processing mechanism

A processing mechanism and pole piece technology, applied in electrode manufacturing, electrode rolling/calendering, etc., can solve problems such as easy formation of wrinkles and affect the quality of pole pieces, and achieve the effect of improving quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The pole piece processing mechanism of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

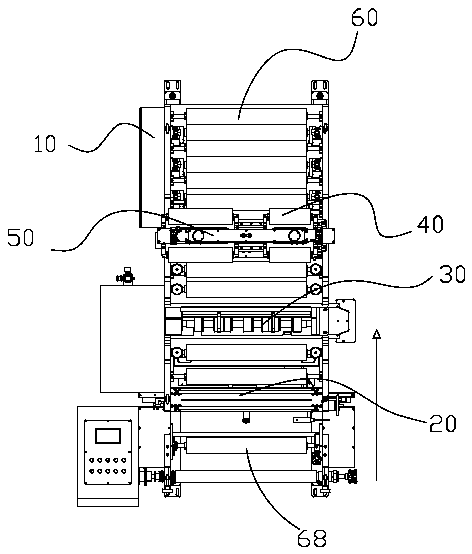

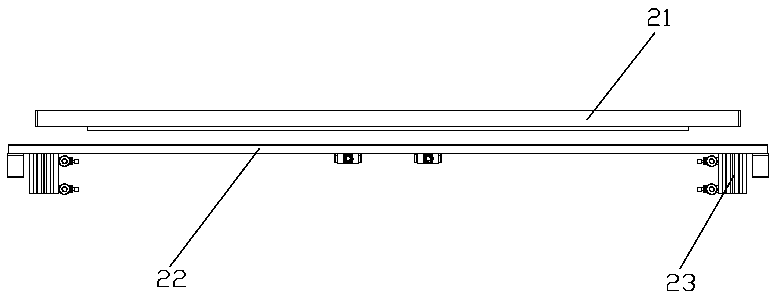

[0020] See figure 1 , a pole piece processing mechanism, which includes a frame 10, on which a beading device 20, a cutter device 30, a guide device 40, two brush devices 50 and a roller device 60 are arranged in sequence from front to back The pole piece to be processed passes through the layering device 20 and the cutter device 30 in sequence, and the cutter device 30 cuts the pole piece into multiple pieces and then sends it to the guide device 40, and the cut multi-piece pole piece passes through the guide device 40. The pole pieces are respectively sent to the brush device 50 , and the pole pieces after being flattened and rolled by the brush device 50 are output through the roller device 60 .

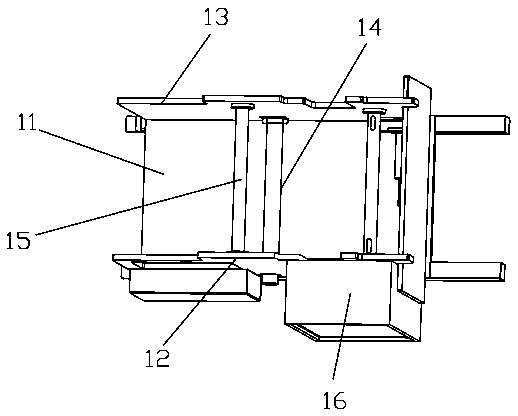

[0021] See also figure 2 , the frame 10 includes a first base plate 11 arranged parallel to the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com