Clutch unit

A clutch and side clutch technology, applied in the direction of clutch, one-way clutch, automatic clutch, etc., can solve the problems of noise, unstable behavior of the outer center spring 119, etc., and achieve the effect of preventing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

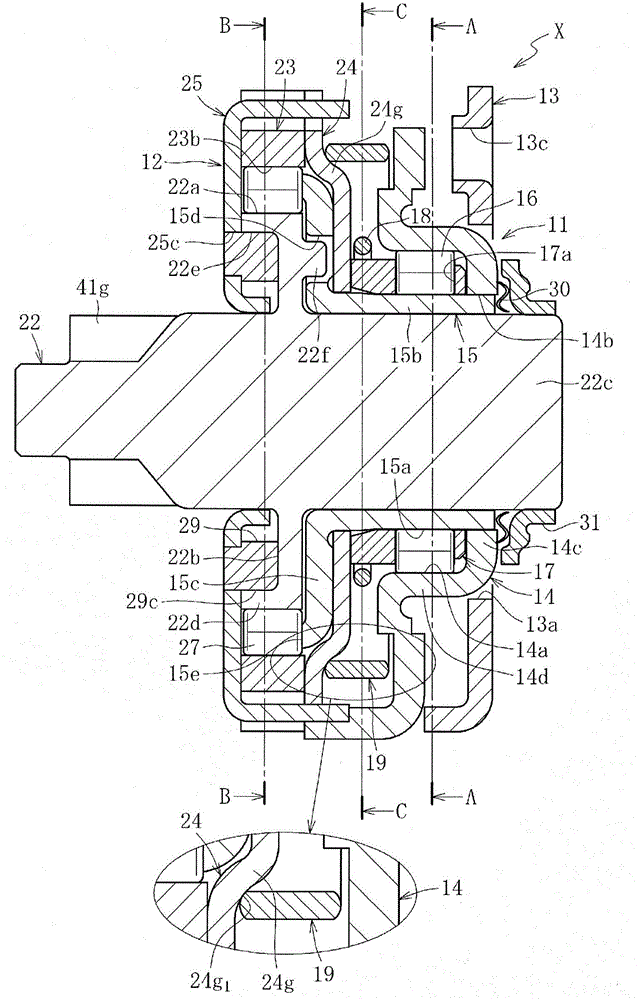

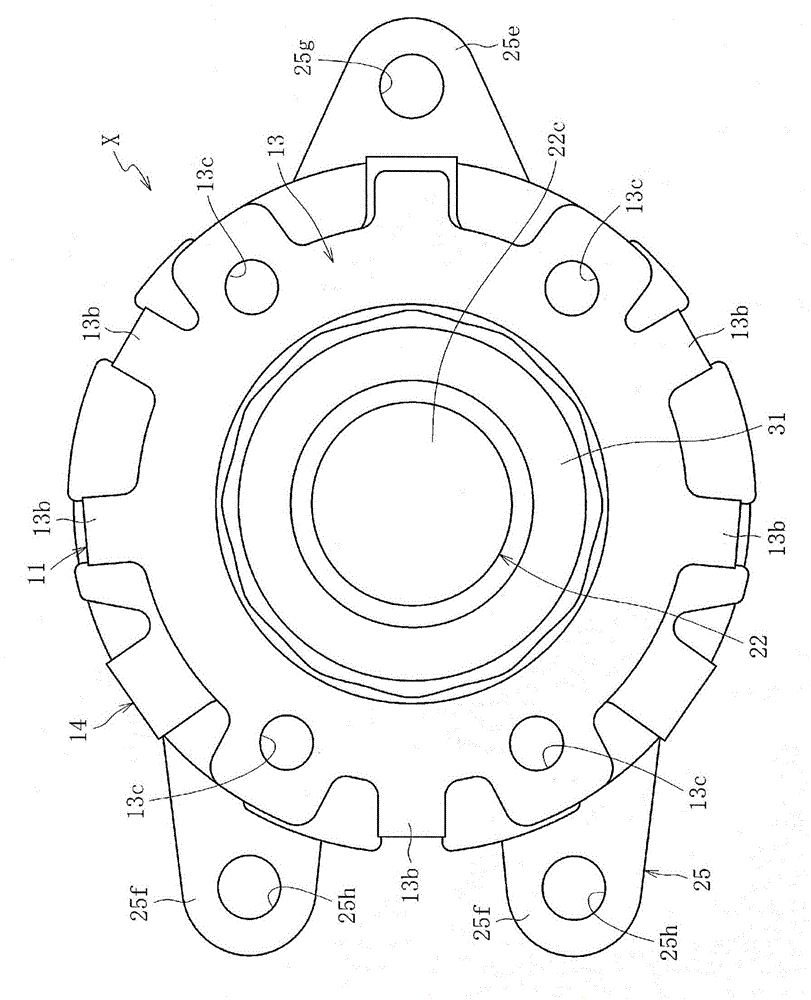

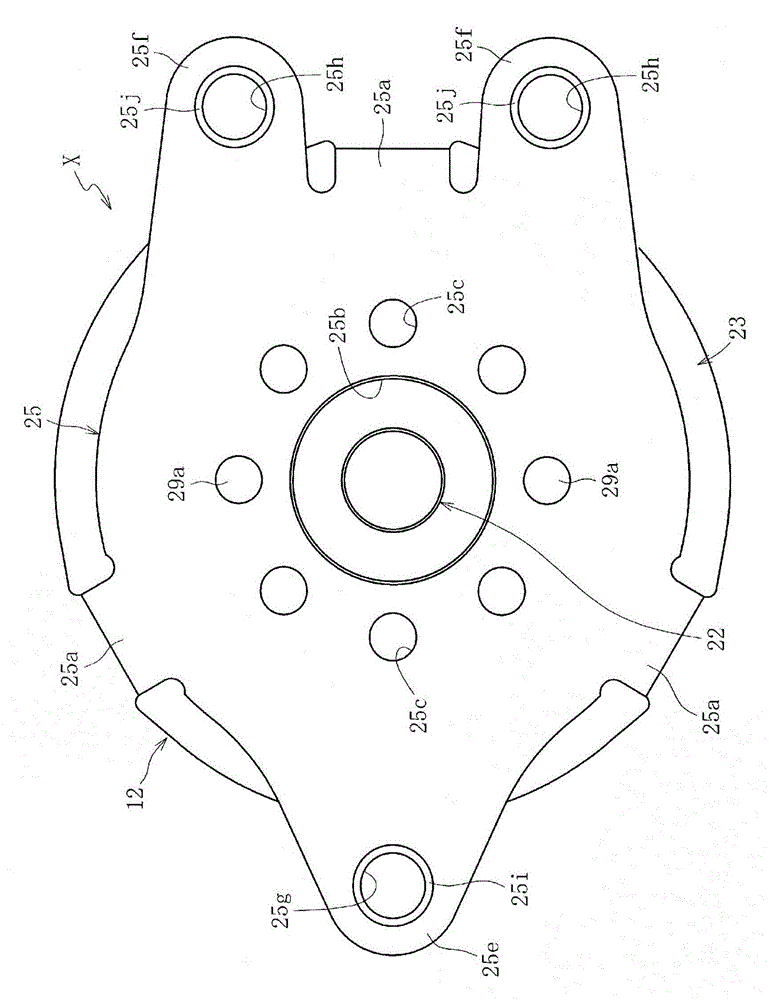

[0099] figure 1 is a longitudinal sectional view showing the overall structure of the clutch unit X in the embodiment of the present invention, figure 2 Yes figure 1 Right side view of clutch unit X shown, image 3 Yes figure 1 Left side view of clutch unit X shown, Figure 4 is along figure 1 Transverse sectional view of A-A, Figure 5 is along figure 1 Lateral cut view of the B-B line. In addition, FIGS. 6 to 18 are diagrams showing main components of the clutch unit X. As shown in FIG. Figure 19~ Figure 31 It is a figure which shows the assembly state of the main structural components of the clutch unit X.

[0100] The clutch unit X is incorporated in, for example, an automotive seat lifter that performs height adjustment of the seat by lever operation (refer to Figure 38 , Figure 39a and Figure 39b )middle. like Figure 1 to Figure 5 As shown, the clutch unit X has a structure in which a lever-side clutch portion 11 provided on the input side and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com