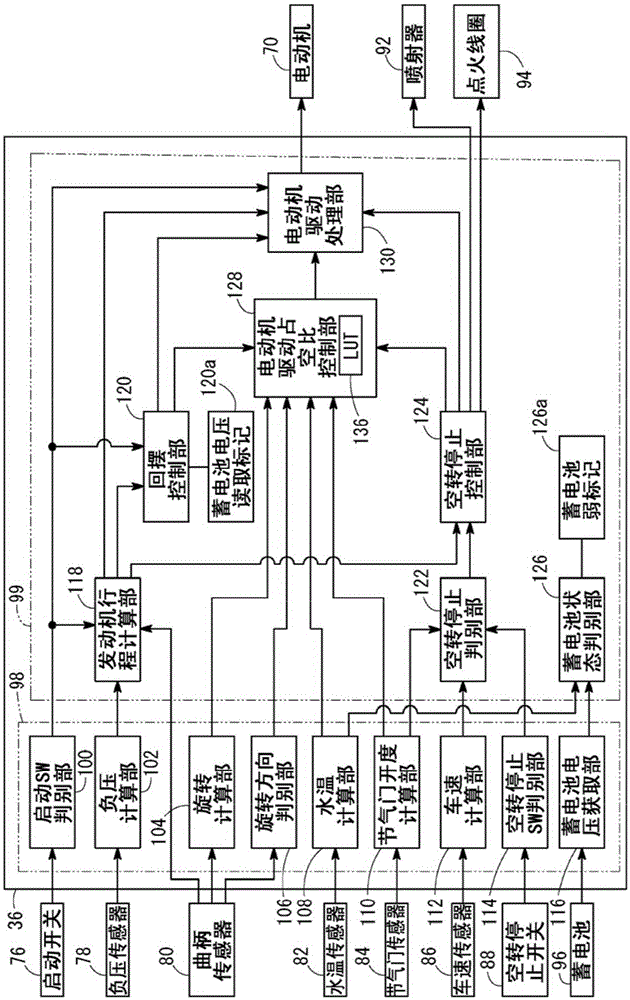

engine control unit

A control device and engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as engine drive and stop, and achieve the effects of restraining power consumption, restraining capacity reduction, and restraining pistons from crossing top dead center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the engine control device according to the present invention will be described in detail with reference to the drawings according to preferred embodiments.

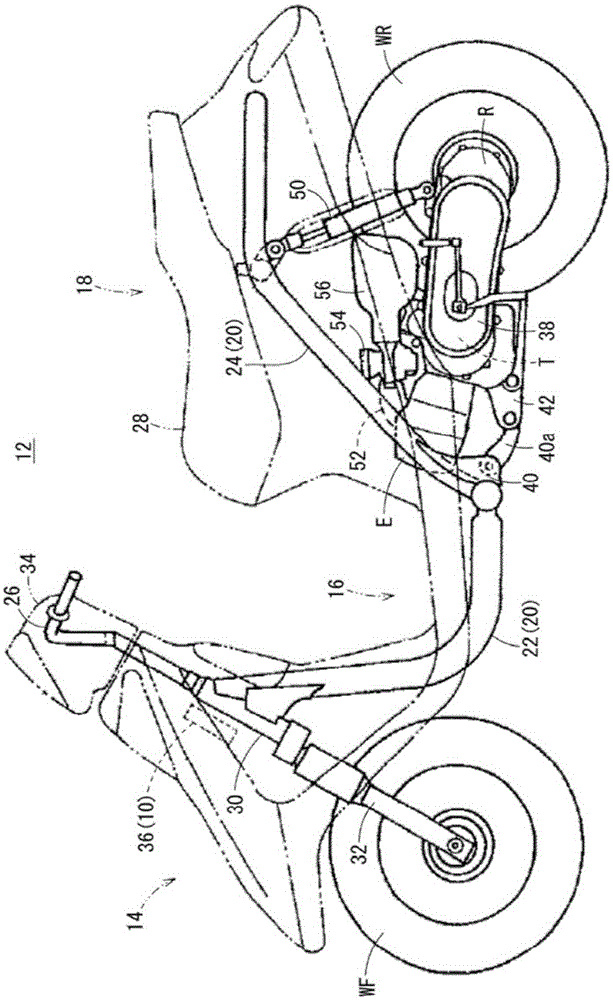

[0034] Such as figure 1 As shown, the engine control device 10 according to one embodiment of the present invention is mounted on a scooter-type motorcycle 12 (hereinafter also simply referred to as a scooter 12 ). In addition, the engine control device 10 of the present invention is not limited to being mounted on the scooter 12, but can also be applied to other types of motorcycles or automobiles.

[0035] A front body 14 and a rear body 16 of the scooter 12 are connected via a low-floor floor 18 . The body frame 20 of the scooter 12 is composed of a down tube 22 bent and extended to the front body part 14 and the low-floor bottom 18, and a main pipe connected to the rear part of the down tube 22 so that the body rear part 16 extends rearward and obliquely upward. 24 and constituted. Furthermore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com