Inner gearing type gear rack power transmission mechanism

A power transmission mechanism, rack and pinion technology, applied in gear vibration/noise attenuation, gear lubrication/cooling, belt/chain/gear, etc., can solve the dead point of crank slider mechanism, difficult to overcome transmission efficiency, dynamic imbalance and other problems, to achieve the effect of saving space, safe and stable transmission, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

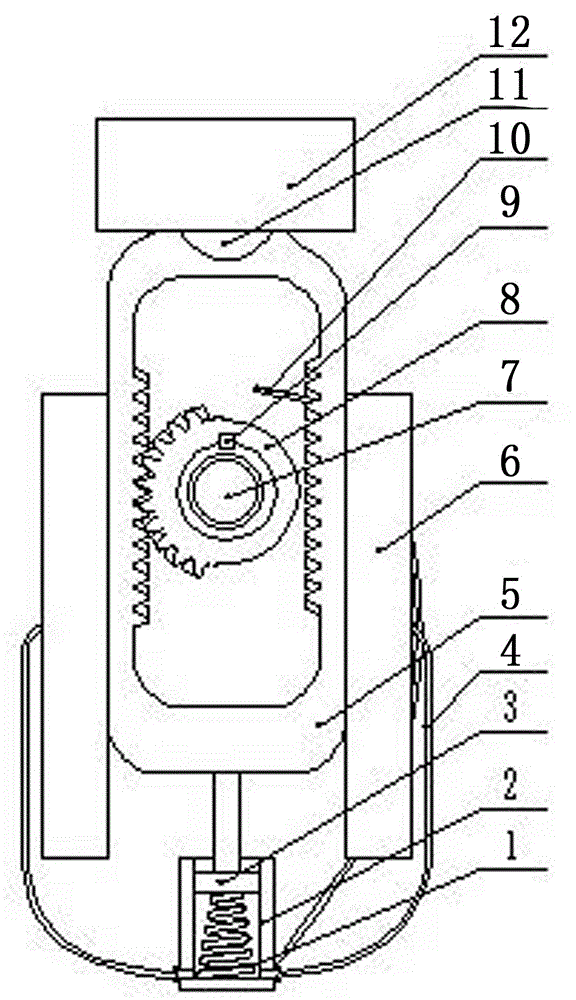

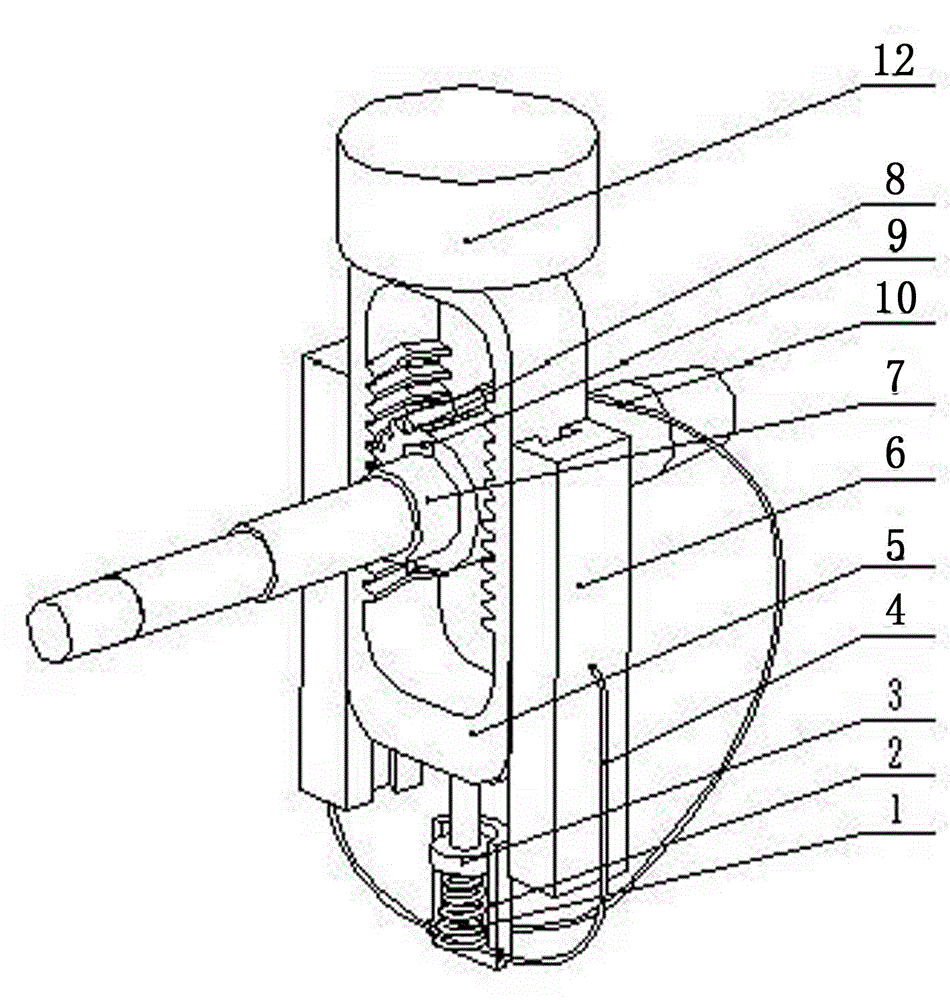

[0012] according to Figure 1~2 The specific structure of the present invention will be described in detail. The internally meshing rack and pinion power transmission mechanism includes a half-gear frame 5, a top piston 12 arranged on the half-gear frame 5, a half-pinion shaft 7 located in the half-gear frame 5, and assembled on the half-pinion shaft 7 through a key 9 The half gear 8 is respectively provided with a rack on the inner wall of the half gear frame 5 left and right sides, and the half gear 8 meshes with the left or right rack in the half gear frame 5. The outer walls of the left and right sides of the half-gear frame 5 are limited in the guide groove of the guide rail 6, the top piston is installed on the half-gear frame 5 through the piston pin 11 through 12, and the bottom piston 3 is arranged coaxially with the top piston 12 on the bottom of the half-gear frame 5 , the bottom piston 3 is limited in the damper cylinder 2 directly below the half-gear frame 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com