One-way valve

A technology of one-way valves and valve bodies, which is applied in the direction of control valves, valve devices, and functional valve types, etc., can solve the problems of cost reduction and processing difficulties, and achieve the effects of cost reduction, easy processing, and leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

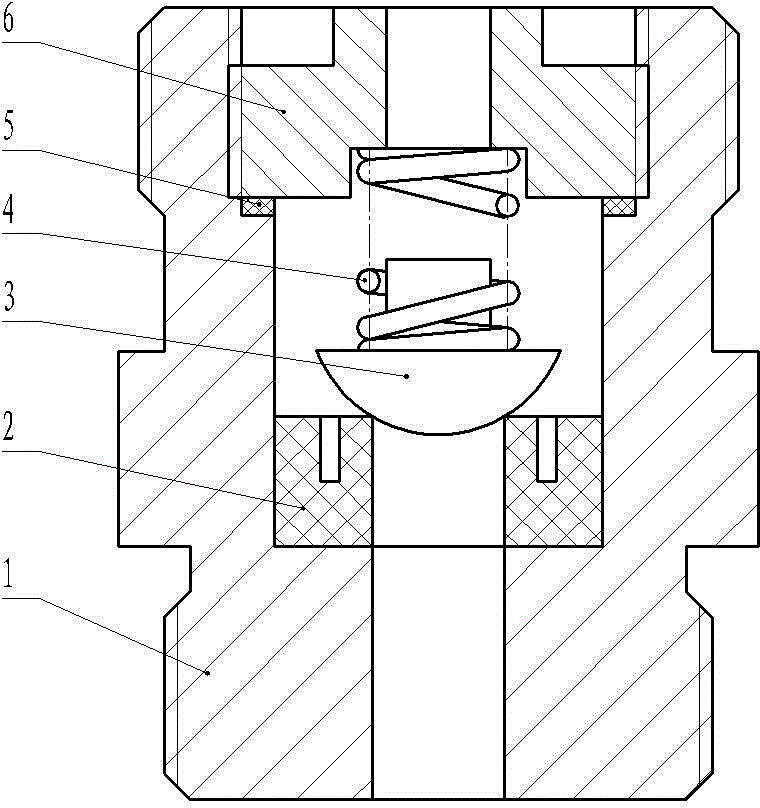

[0012] Such as figure 1 The shown one-way valve includes a valve body 1, the inner cavity of the valve body 1 is equipped with a valve plug 3, a spring 4 and a spring seat 6 sequentially from the inside to the outside, the valve plug 3 has a spherical sealing surface, and the valve plug 3 A spring guide rod is connected, and a rubber sealing block 2 embedded in the valve body is installed between the valve plug 3 and the valve body 1. The rubber sealing block 2 has a fluid passage, and one end of the rubber sealing block 2 near the valve plug 3 is provided with a fluid The ring groove on the outside of the channel mouth; the spring seat 6 is provided with a fluid channel and a spring limit groove, the spring seat 6 is installed on the valve body 1 through threads, and a gasket 5 is installed at the contact end surface of the valve body 1 and the spring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap