Vertical type enameled flat wire production line

A technology of enameled flat wire and production line, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve the problems of inconvenient production, incompatibility, complex process, etc., to facilitate maintenance, reduce maintenance costs, and reduce operation difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

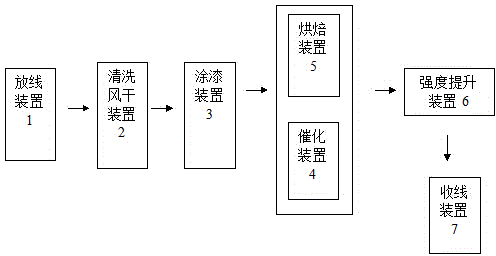

[0014] A vertical enamelled flat wire production line, the production line includes a pay-off device 1, a cleaning and air-drying device 2, a painting device 3, a catalytic device 4, a baking device 5, a strength raising device 6 and a wire take-up device 7, and the pay-off device passes through The cleaning and air-drying device is connected with the painting device, and a catalytic device and a baking device independent of each other are arranged on the rear side of the painting device, and the rear side of the catalytic device and the baking device is connected with the wire take-up device through a strength raising device.

[0015] The catalytic device and the baking device are arranged above the factory building to facilitate the treatment of exhaust gas and reduce the impact on the interior of the factory building; the catalytic device and the baking device are arranged in a vertical stacking manner, and the baking device is located above the catalytic device. According t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap