Small-diameter hollow blank transverse rolling precision forming method of mandril control

A hollow billet and cross wedge rolling technology, which is applied to engine components, cylinders, mechanical equipment, etc., can solve the problems of large machining allowance, high scrap rate, and poor quality of target products, and achieve the goal of expanding the scope of application and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

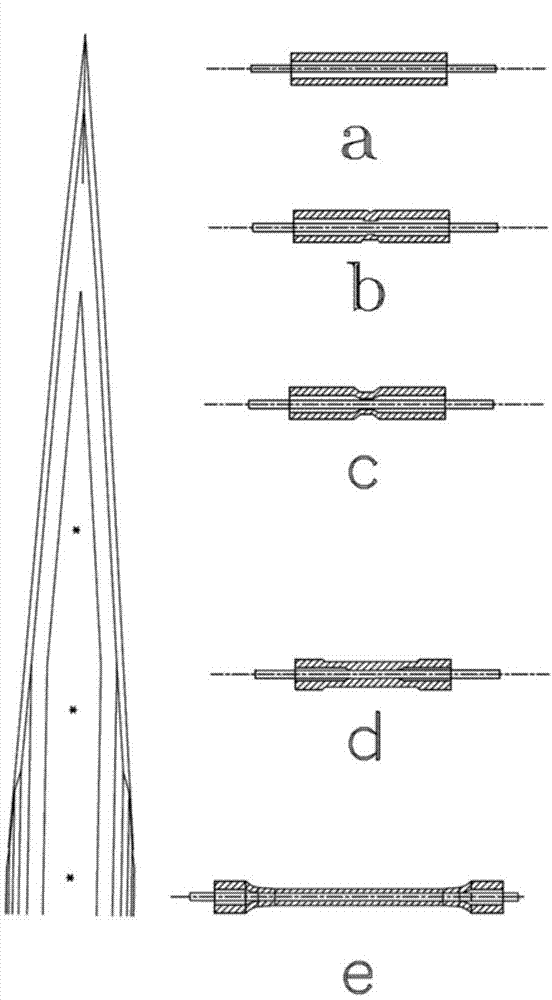

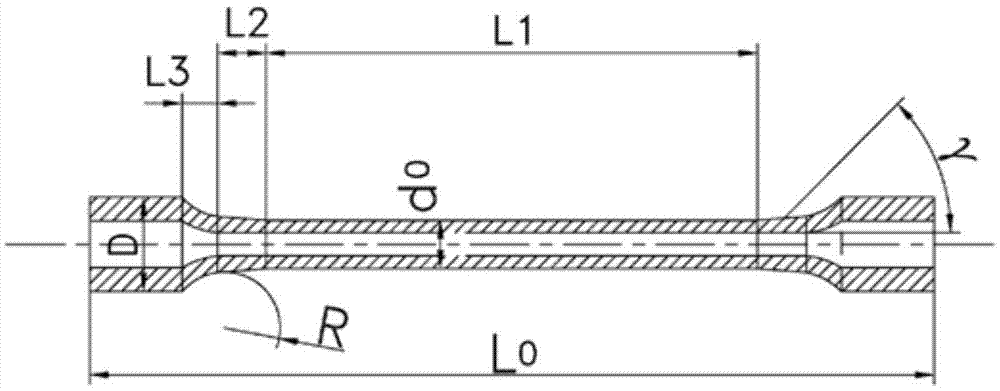

[0033] Such as figure 1 , figure 2 , image 3 Shown is an example of precise forming of a small-diameter hollow billet cross-wedge rolling controlled by a mandrel.

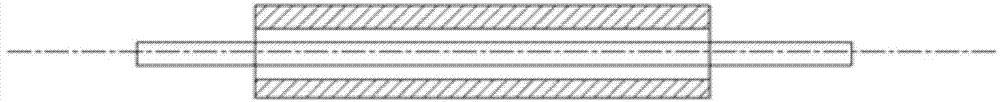

[0034] Install the mold with forming angle α=35° and widening angle β=5° on the cross-wedge rolling mill, and adjust the corresponding positional relationship of the cross-wedge rolling mill. The mold diagram is as follows figure 1 As shown, the hollow bar with a diameter of Ф20mm and a length of 120mm is heated to 1100°C by an electromagnetic induction furnace, and then a heat-treated mandrel is loaded into it, and the feeding device is placed between the upper and lower molds to start the rolling mill. After the roll rotates one revolution, it is obtained as image 3 The hollow billet (length L = 125mm, outer diameter D = 10.5mm, inner diameter d = 4.6mm, uniform wall thickness) is shown, and the precise forming of the hollow billet cross wedge rolling billet has been completed so far.

Embodiment 2

[0036] With forming angle α=32 °, the mold ( figure 1 As shown) installed on the cross wedge rolling mill, adjust the corresponding positional relationship of the cross wedge rolling mill, heat the hollow valve bar with a diameter of Ф18mm and a length of 90mm through an electromagnetic induction furnace to 1000°C, and then put it into the mandrel after heat treatment , put the feeding device between the upper and lower molds, start the rolling mill, and get the following after the roll rotates one week Figure 4 The hollow blank that meets the requirements is shown (length L=116mm, outer diameter D=11mm, inner diameter d=3.2mm, uniform wall thickness).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com