Batch pipe orifice deburring method

A technology for deburring and pipe fittings, which is applied to workpieces, accessories of tool holders, turning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

[0017] A kind of deburring method of pipe nozzles in batches of the present invention comprises the following steps,

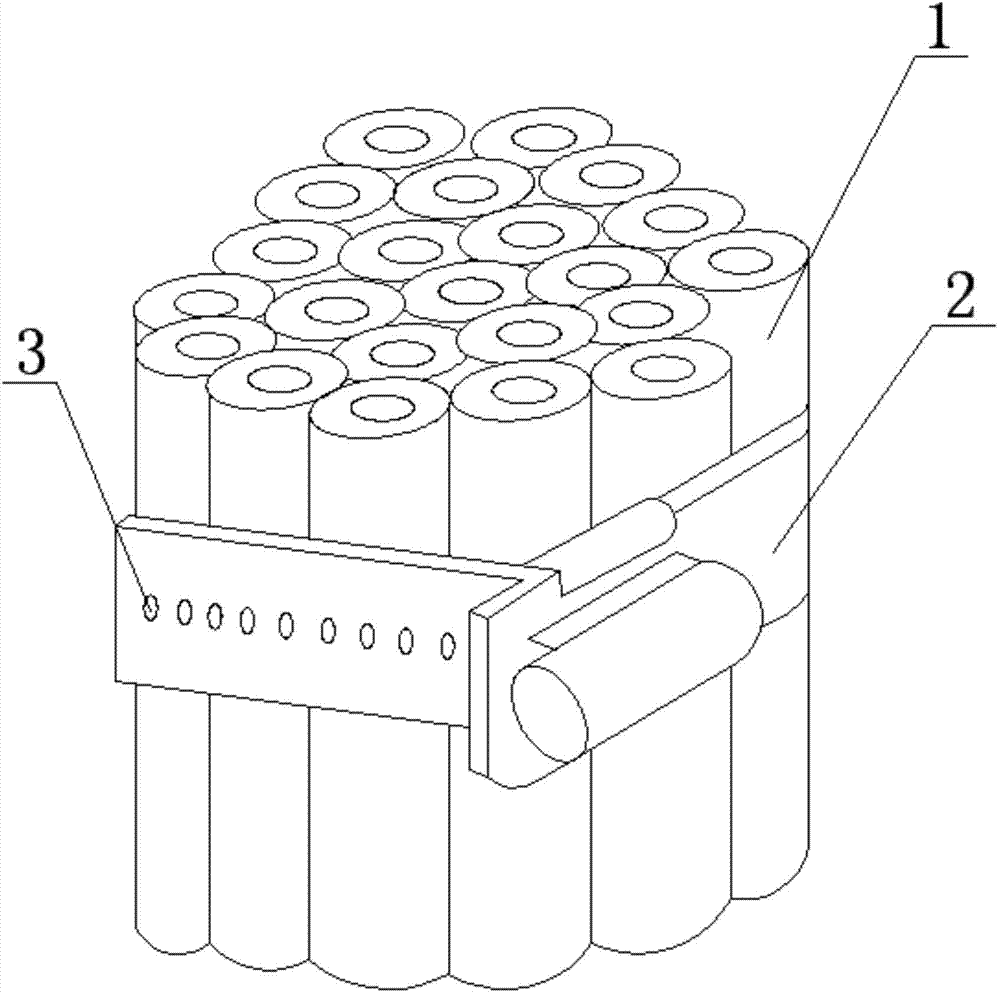

[0018] 1). Neatly stack batches of pipe fittings 1 together;

[0019] 2). Bundle the batches of pipe fittings 1 together with pipe clamps 2;

[0020] 3). Replace the drill bit on the drilling machine with a dimple drill bit;

[0021] 4). Turn on the drilling machine, and align the nozzle at one end of the bundled pipe fitting 1 with the dimple bit in turn to deburr the nozzle. After completion, align the nozzle at the other end of the pipe fitting 1 with the dimple bit in turn, and repeat the above operations. Deburring;

[0022] 5). Untie the pipe clamp 2, arrange the batch of pipe fittings 1 that have been deburred, and then repeat steps 1 to 5.

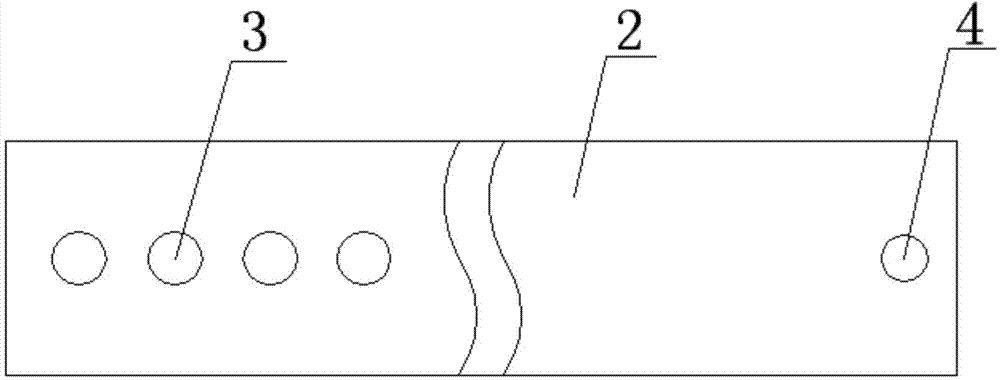

[0023] In order to facilitate bundling, a number of small holes 3 are opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com