Back board mold

A mold and backplane technology, applied in the field of backplane molds, can solve the problems of product quality degradation, low service life, low processing accuracy, etc., and achieve the effects of convenient disassembly and maintenance, low manufacturing cost, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

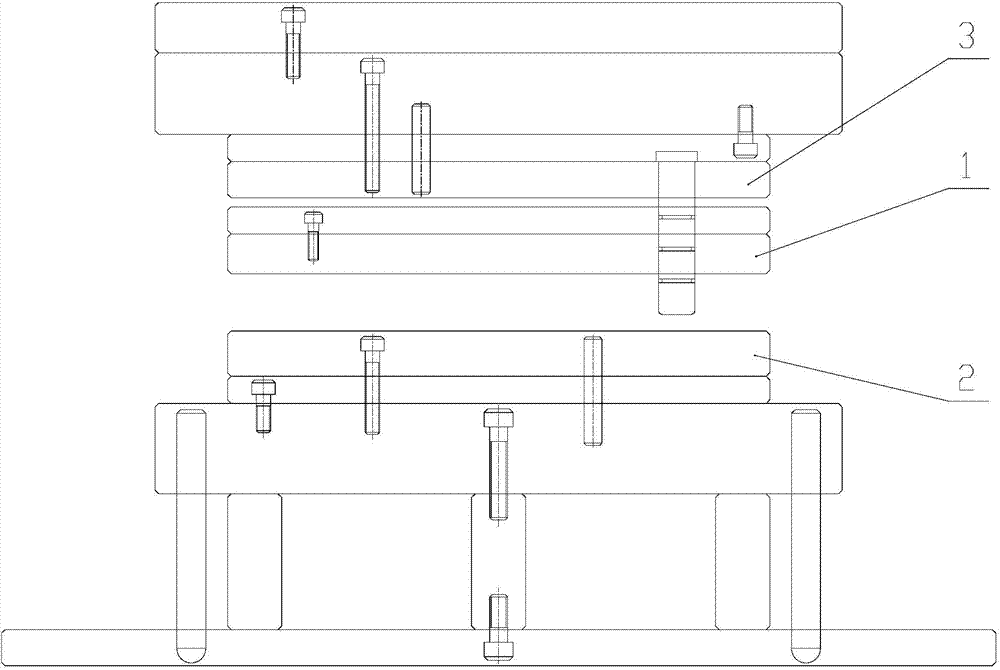

[0020] figure 1 It is a structural schematic diagram of the backplane mold provided by this preferred embodiment. A kind of backboard mould, comprises upper formwork 1, the lower formwork 2 that forms mold cavity with upper formwork 1, and the upper supporting plate 3 that is provided with on upper formwork 1, wherein, set between upper formwork 1 and upper supporting plate 3 There is a buffer element, which can buffer the impact of pressing the template to improve the uniformity of the back plate, and at the same time avoid the problem that the thickness of the back plate changes and cause the mold to be unsuitable. The upper template 1 is connected to the stamping device; the upper template 1 There is an air vent connected with the mold cavity, and an air extraction device is also provided at the air vent; each side of the upper template 1 is provided with a first sealing strip, and each side of the lower template 2 is provided with a The second sealing strip, the first sea...

Embodiment 2

[0024] This preferred embodiment provides a back plate mold, the structure of which is basically the same as that of the preferred embodiment 1. The back plate mold includes an upper template, a lower template forming a mold cavity with the upper template, and an upper supporting plate provided on the upper template , wherein, a buffer element is provided between the upper template and the upper supporting plate, and the upper template is connected with a stamping device; the upper template is provided with a vent hole connected with the mold cavity, and an air extraction device is also provided at the vent hole; the upper template Each side of the lower formwork is provided with a first sealing strip, each side of the lower formwork is provided with a second sealing strip, and the first sealing strip can abut against the second sealing strip to make the mold cavity in a closed state.

[0025] The difference is that the buffer element is not limited to the spring, but can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com