Engine

A technology for engines and hoods, which is applied in the field of auto parts, and can solve the problems of shedding and engine edge glue peeling off, etc., to achieve the effects of preventing movement, facilitating processing, and avoiding glue peeling or peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

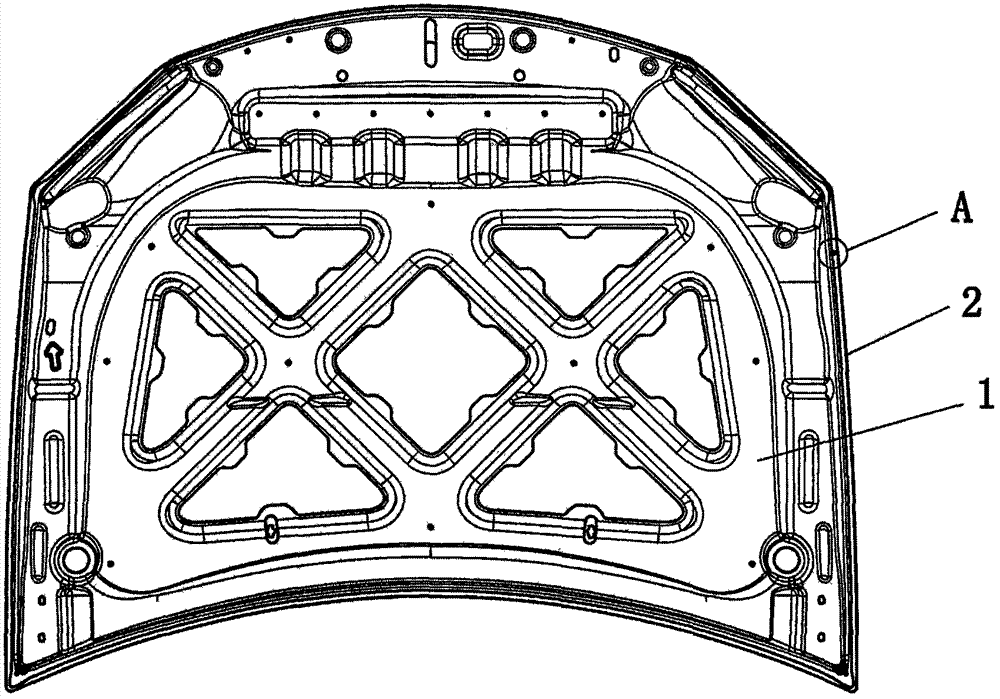

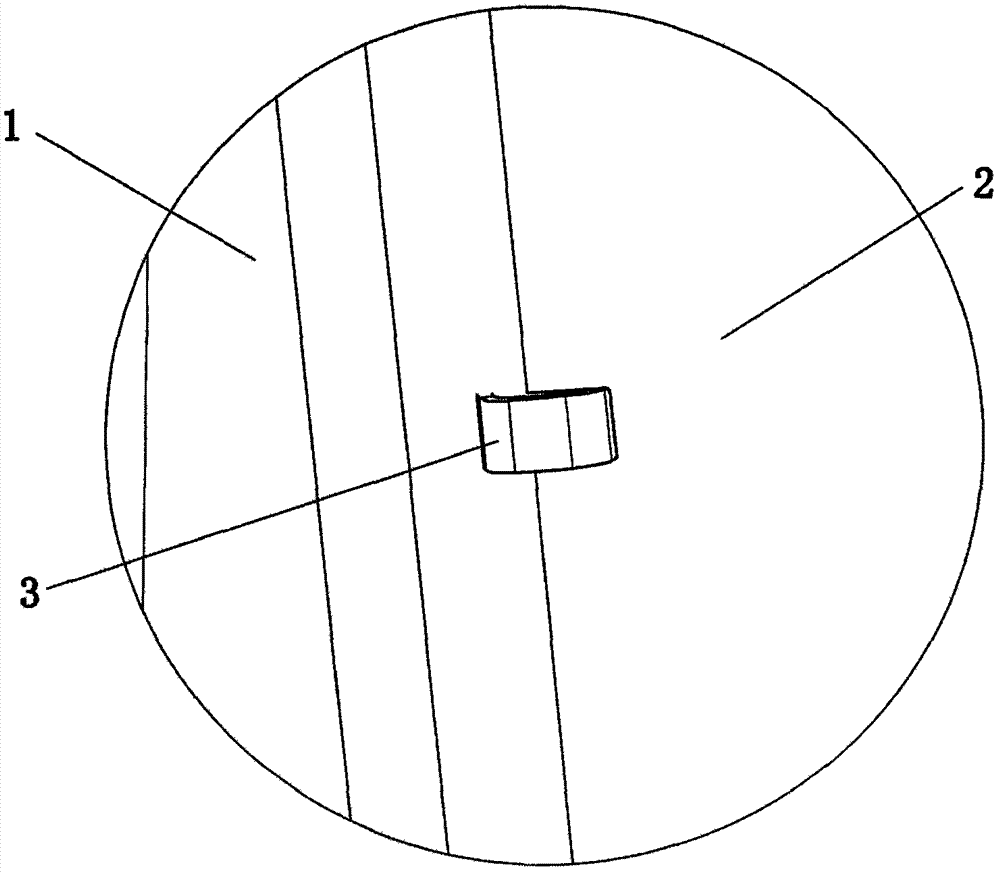

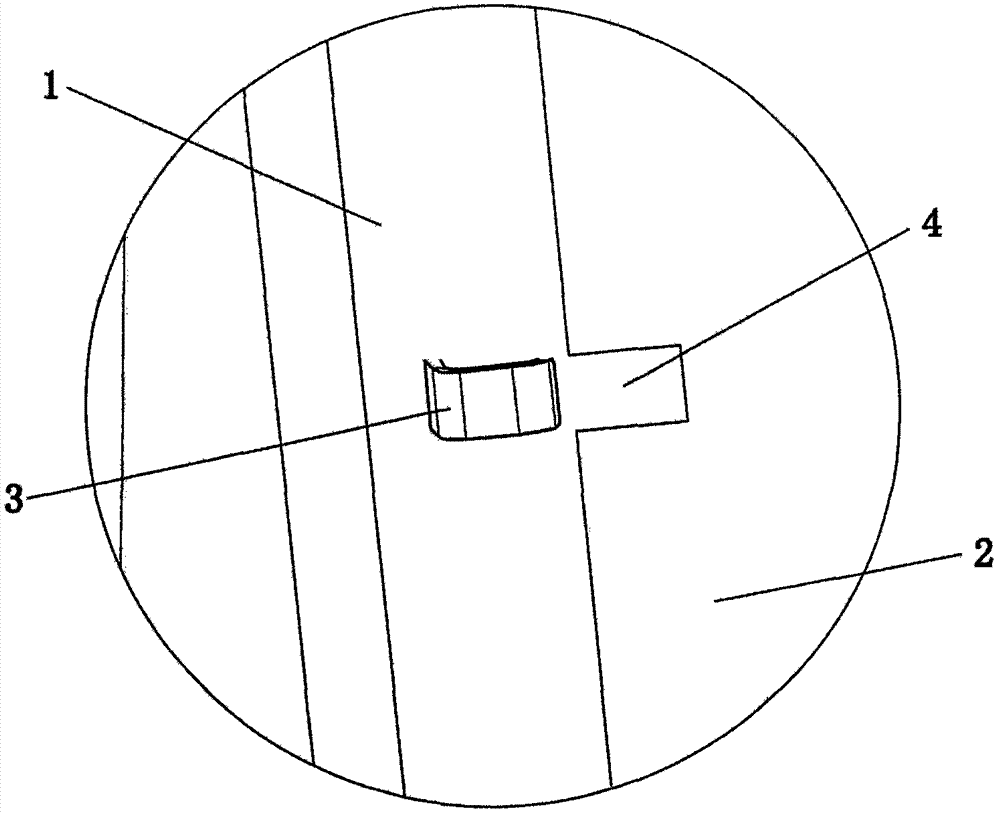

[0017] Embodiment 1: as figure 1 , 2 , Shown in 3,4, engine comprises hood inner panel 1 and hood outer panel 2, and hood inner panel 1 and hood outer panel 2 are axisymmetric structures. The edge of the hood inner panel 1 is processed with six position-limiting bosses 3 , and the six position-limiting bosses 3 are axisymmetrically distributed with respect to the axis of symmetry of the hood inner panel 1 . The cross-sectional thickness of the limiting boss 3 is the same as that of the hood inner panel 1, that is, the limiting boss 3 can be integrally formed with the hood inner panel 1 through a stamping process, and the stamping height of the limiting boss 3 is 1 twice the thickness and a width of 4mm. Process six limit grooves 4 matching the width of the limit boss 3 on the edge of the hood outer panel 2 .

[0018] When the hood inner panel 1 overlaps with the hood outer panel 2, insert the limiting boss 3 on the hood inner panel 1 into the limiting groove 4 on the hood o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com