Binding devices for steel pipes

A steel pipe and binding belt technology, applied in the field of steel pipe binding devices, can solve the problems of time required for replacement of tightening ropes, increased production costs, and easy dispersal of long strips, and achieves simple structure, extended service life, and clamping operation. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

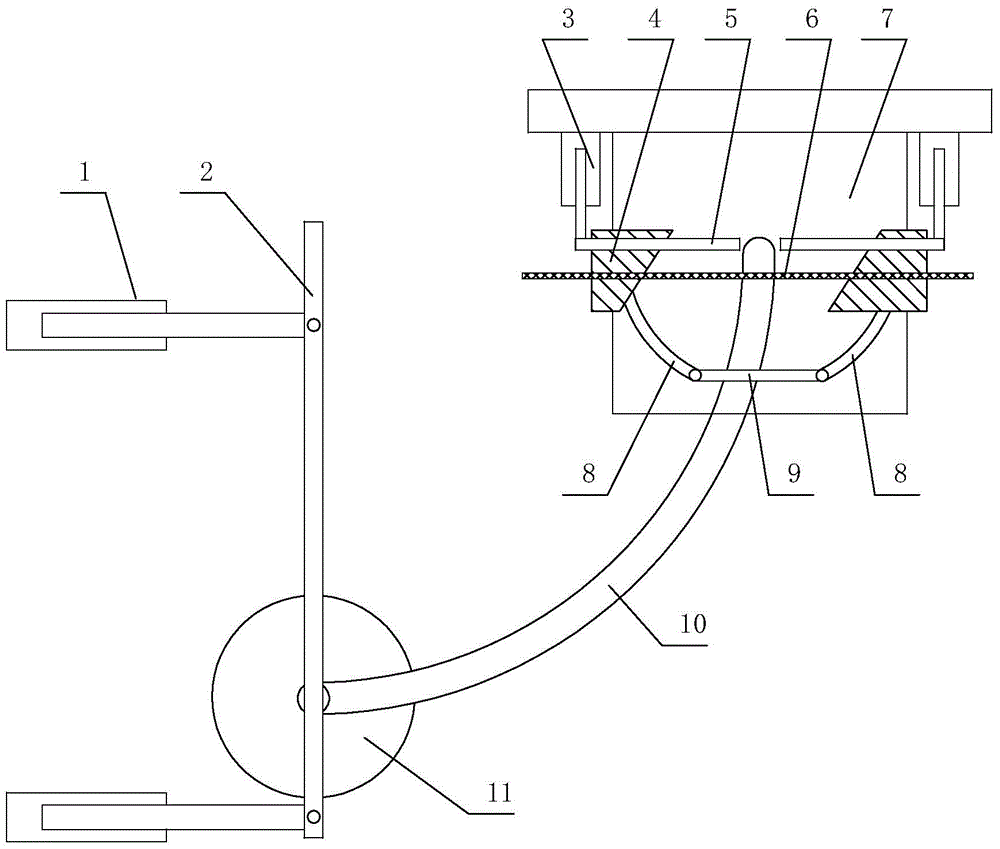

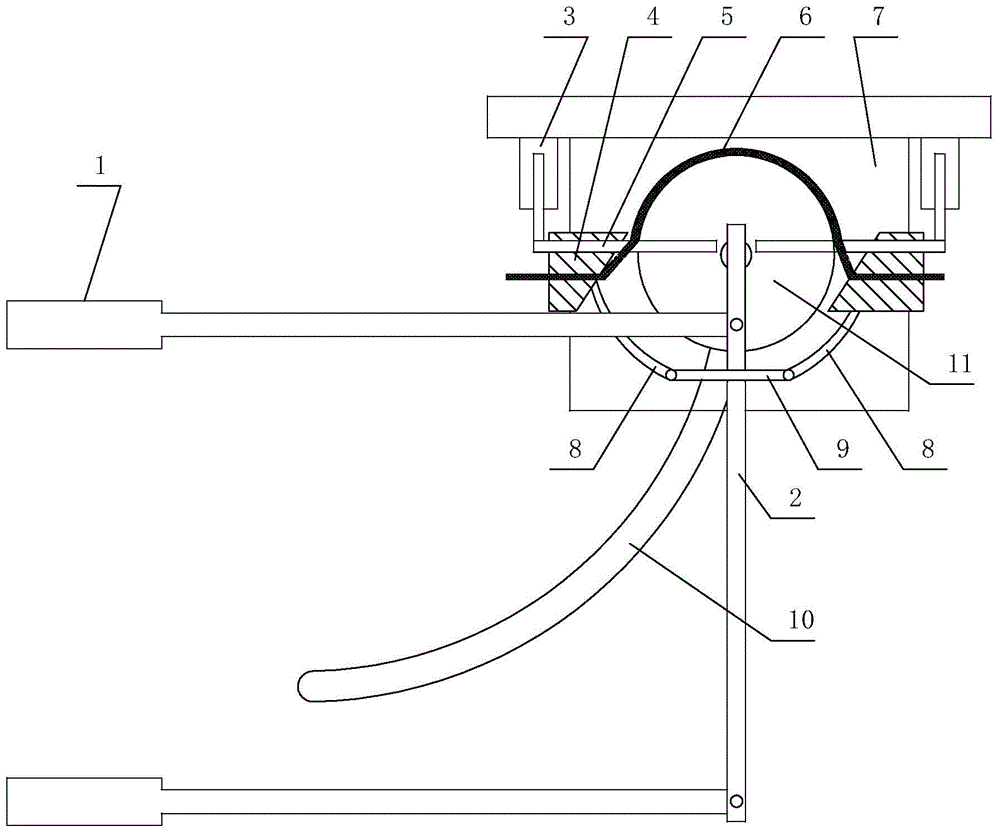

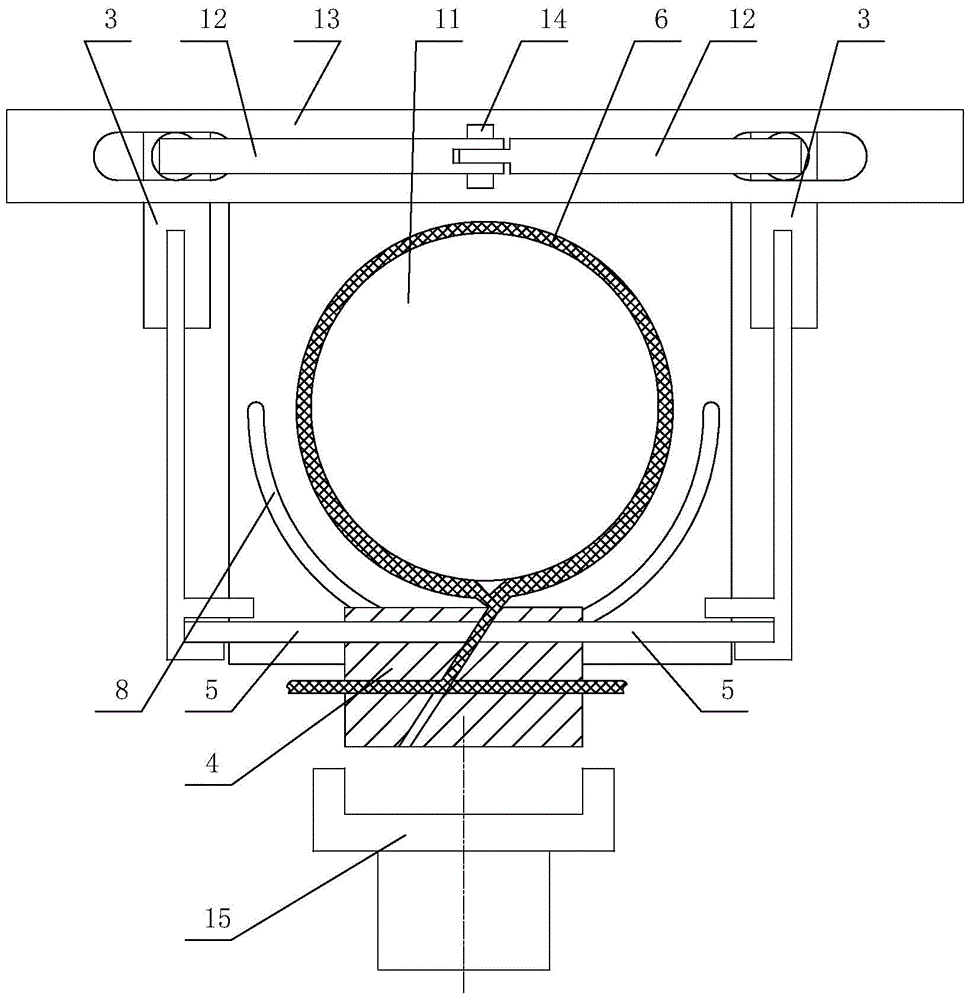

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Depend on Figure 1 to Figure 8 It can be seen from the structural schematic diagram of the binding device of the present invention for steel pipes that it includes a clamping device 11, a conveying device, a binding device and a rope twisting device, the clamping device 11 is slidingly connected with the conveying device, and the binding device passes through The track is connected with the conveying device, and the rope twisting device is disconnected or connected with the binding device. The binding device includes a bottom plate 7, two sets of binding assemblies located on both sides of the steel pipe, and a driving assembly that drives the two sets of binding assemblies to approach or move away from each other at the same time.

[0034]Each group of binding components includes a binding cylinder 3, a binding block 4 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com