Adsorption decoloring method for vegetable oil

A technology for adsorption and decolorization and vegetable oil, which is applied in the field of adsorption and decolorization of vegetable oil and can solve problems such as affecting the appearance of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

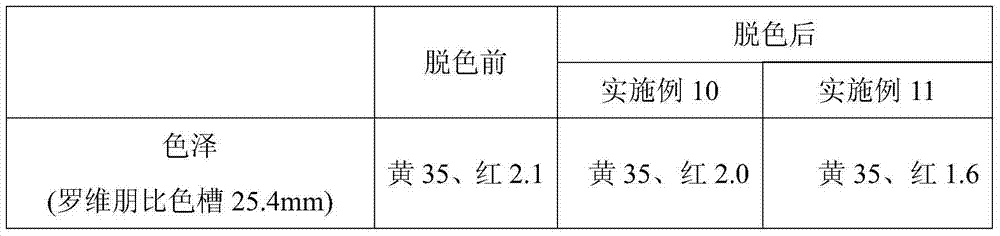

Examples

Embodiment 1

[0019] An adsorption decolorization method for vegetable oil, comprising the following steps: first micronizing the vegetable oil so that the average particle diameter of the oil droplets of the vegetable oil is less than 200nm;

Embodiment 2

[0021] A method for adsorption and decolorization of vegetable oil, comprising the following steps: firstly, the vegetable oil is micronized with an ultra-high pressure homogenizer, so that the average particle diameter of the oil droplets of the vegetable oil is less than 200nm, and then transferred to a decolorization tank for adsorption and decolorization, after the decolorization is completed filter.

Embodiment 3

[0023] A method for adsorption and decolorization of vegetable oil, comprising the following steps: firstly, the vegetable oil is micronized with a nano collider so that the average particle size of oil droplets of the vegetable oil is less than 200nm, and then transferred to a decolorization tank for adsorption and decolorization, and then filtered after the decolorization is completed .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com