Ion nitriding tool for marine crankshaft

A technology for nitriding tools and crankshafts, applied in metal material coating process, coating, solid-state diffusion coating, etc. It does not meet the nitriding requirements and other problems, and achieves the effect of consistent nitriding effect, eliminating glow dead corners, and improving product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described:

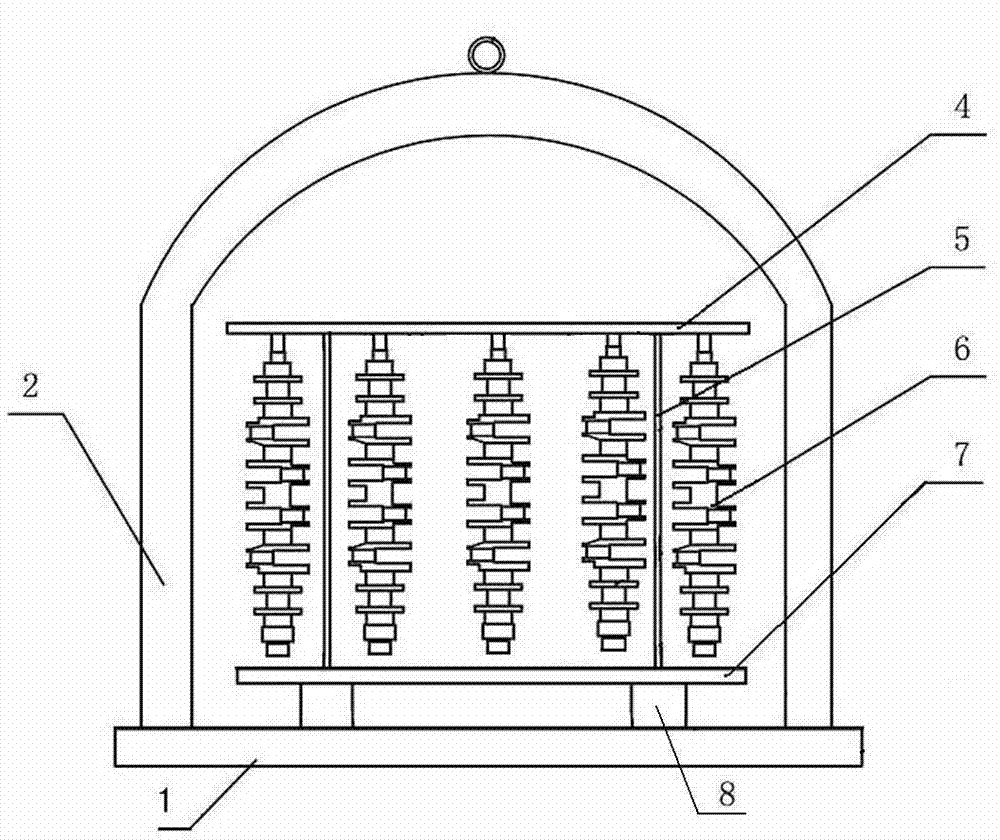

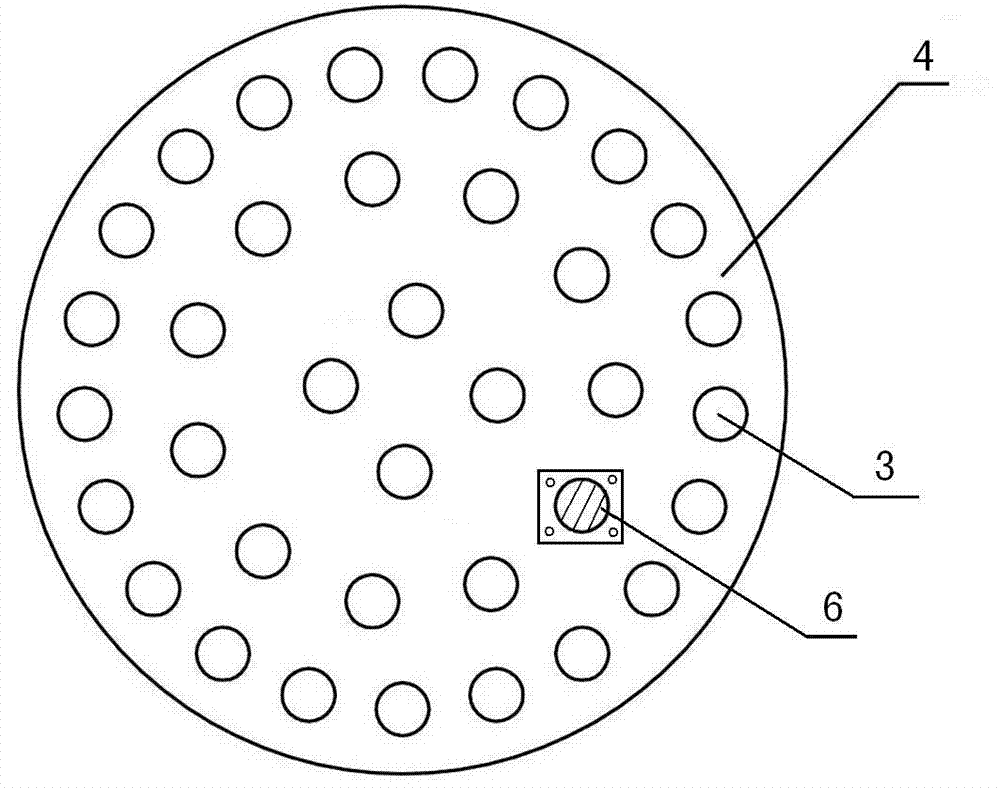

[0012] figure 1 and figure 2 The ion nitriding tool for the marine crankshaft includes a nitriding hanger arranged in the furnace cavity formed by fastening the furnace shell 2 and the furnace bottom support plate 1, and the nitriding hanger includes a cathode hanging plate 4 and a cathode support 5, The cathode hanging plate 4 is installed on the top of the cathode support 5, and the bottom of the cathode support 5 is fixed on the cathode plate 7, and the cathode plate 7 is fixed on the furnace bottom support plate 1 by an insulating support plate support 8. The cathode hanging plate 4 is provided with a crankshaft hanging hole 3 for hanging the crankshaft 6. The crankshaft hanging hole 3 is uniformly arranged in the circumferential direction from the inner ring, the middle ring and the outer ring. The distance between the inner ring and the middle ring of the crankshaft hanging hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com