Method for synthesizing silicon nitride powder by using high-temperature rotary furnace

A technology of silicon nitride powder and silicon nitride powder, which is applied in the field of synthesizing silicon nitride powder and synthesizing silicon nitride powder by using a high-temperature rotary furnace, can solve the problem of difficulty in realizing large-scale industrial production, complicated process control and poor sintering quality. Stability and other issues, to achieve the effect of reducing the milling process, less process flow, and shortening the nitriding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

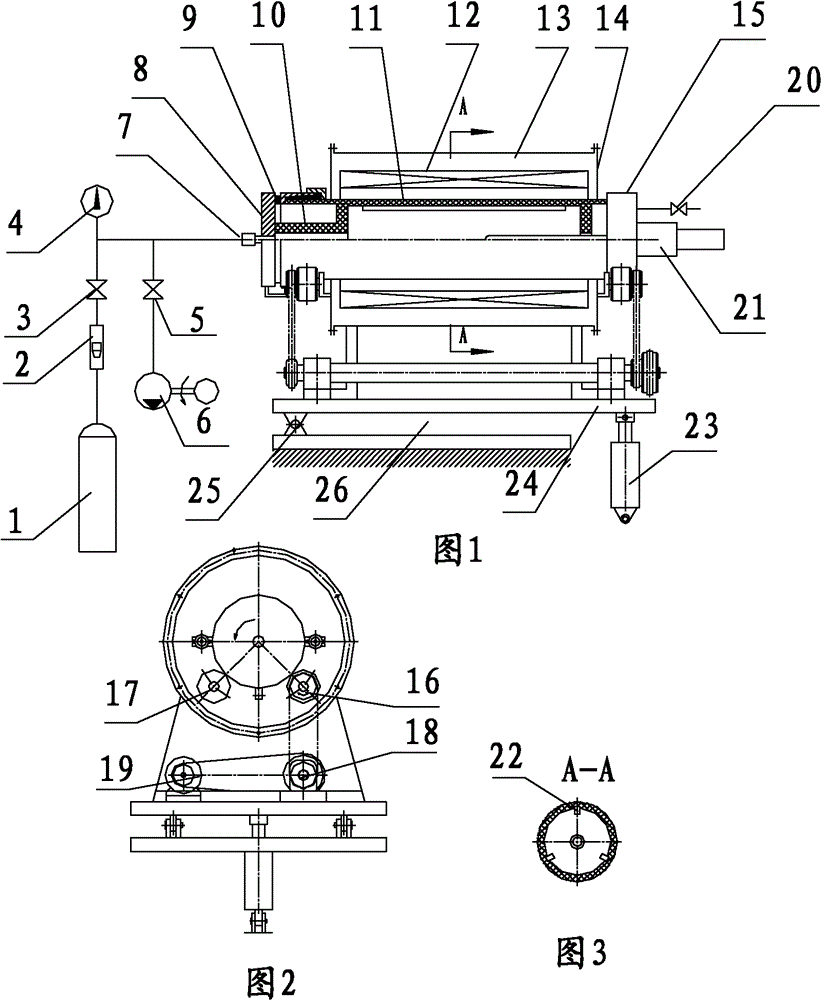

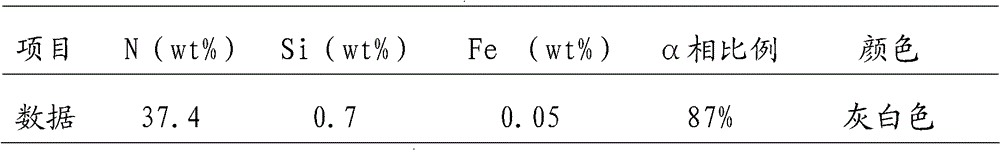

[0054] Mix high-purity silicon powder and silicon nitride powder as a diluent at a ratio of 100:20, put it into the nitriding zone of the rotary furnace, put it into the furnace door baffle plate 10, and close the furnace door 8.

[0055] Turn on the power supply of the furnace body, start the rotary switch of the furnace body, and the rotation speed is 1 revolution / min; heat up, the temperature rise rate is controlled at 3°C / min, and when the temperature reaches 350°C, close the exhaust valve 20, start the vacuum pump 6, and open the vacuum valve 5. Keep the vacuum in the furnace up to 100Pa, continue to heat up to 650°C with the same heating system, close the vacuum valve 5, open the nitrogen valve 3, and feed nitrogen into the furnace, and at the same time adjust the exhaust valve 20 to keep the furnace The nitrogen pressure is 0.03MPa, and the temperature is continuously raised to 1050°C at a heating rate of 3°C / min. When the temperature is above 850°C, vacuuming is carried...

Embodiment 2

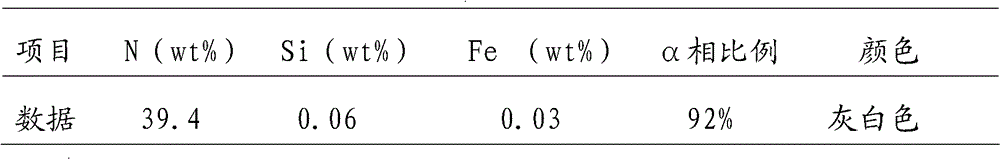

[0062] Mix high-purity silicon powder and silicon nitride powder as a diluent at a ratio of 100:20, put it into the nitriding zone of the rotary furnace, put it into the furnace door baffle plate 10, and close the furnace door 8.

[0063] Turn on the power supply of the furnace body, start the rotary switch of the furnace body, and the rotation speed is 1 revolution / min; heat up, the temperature rise rate is controlled at 3°C / min, and when the temperature reaches 450°C, close the exhaust valve 20, start the vacuum pump 6, and open the vacuum valve 5. Keep the vacuum in the furnace up to 300Pa, continue to heat up to 750°C with the same heating system, close the vacuum valve 5, open the nitrogen valve 3, and feed nitrogen into the furnace, and at the same time adjust the exhaust valve 20 to keep the furnace The nitrogen pressure is 0.05MPa, and the temperature is continued to rise to 1150°C at a heating rate of 3°C / min. When the temperature is above 950°C, vacuuming is carried o...

Embodiment 3

[0070] Mix high-purity silicon powder and silicon nitride powder as a diluent at a ratio of 100:50, put it into the nitriding zone of the rotary furnace, put it into the furnace door baffle plate 10, and close the furnace door 8.

[0071] Turn on the power supply of the furnace body, start the rotary switch of the furnace body, and the rotation speed is 10 revolutions / min; heat up, the temperature rise rate is controlled at 3°C / min, and when the temperature reaches 350°C, close the exhaust valve 20, start the vacuum pump 6, and open the vacuum valve 5. Keep the vacuum in the furnace up to 100Pa, continue to heat up to 650°C with the same heating system, close the vacuum valve 5, open the nitrogen valve 3, and feed nitrogen into the furnace, and at the same time adjust the exhaust valve 20 to keep the furnace The nitrogen pressure is 0.03MPa, and the temperature is continuously raised to 1050°C at a heating rate of 3°C / min. When the temperature is above 850°C, vacuuming is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com