Steel damping limiting unidirectional moving pot type rubber support seat

A rubber bearing and steel damping technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of not being able to fully exert the seismic capacity of bridge piers, low horizontal seismic force, and large internal seismic force, so as to improve the seismic capacity and improve efficiency , the effect of easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

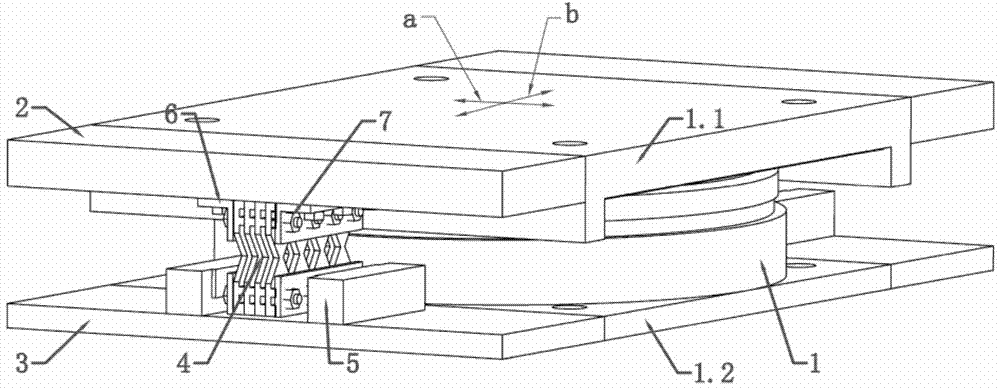

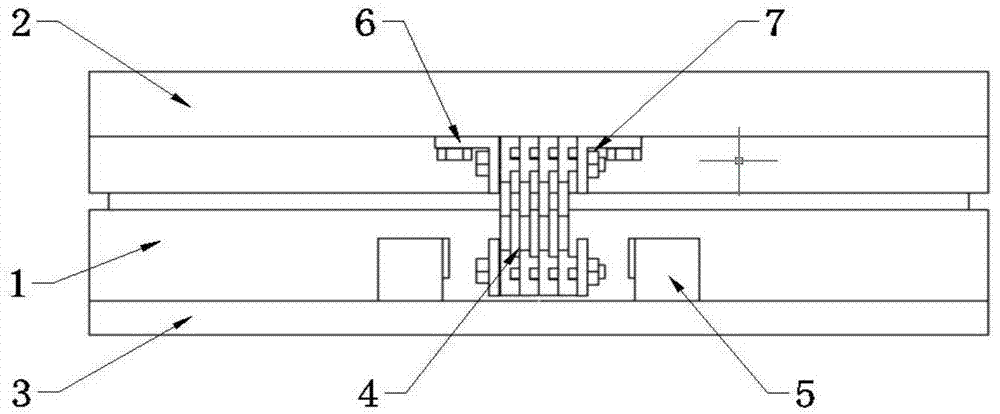

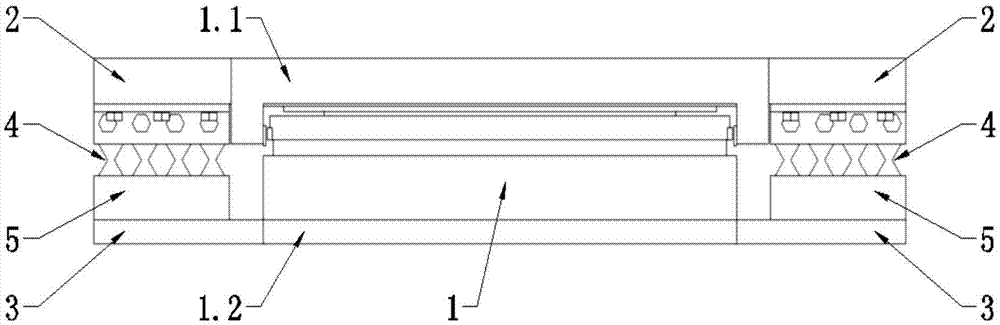

[0029] figure 1 , figure 2 and 3 As shown, a specific embodiment of the present invention is: a steel damping limit one-way movable pot rubber bearing, including a one-way movable pot rubber bearing 1, characterized in that: the one-way movable pot rubber The two inactive sides of the top plate 1.1 of the support 1 are fixedly connected to the top plate extension plate 2, and the bottom surface of the top plate extension plate 2 hangs an X-shaped steel plate damper 4; the two inactive sides of the bottom basin 1.2 of the one-way movable basin rubber support 1 The bottom basin extension plate 3 is fixedly connected, and the upper surface of the bottom basin extension plate 3 is welded with two stoppers 5; the X-shaped steel plate damper 4 is located between the two stoppers 5, and between the stopper 5 and the X-shaped steel plate damper 4 The interval between them is 50-300mm (the allowable displacement of the corresponding specification bearing stipulated in the traffic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com