Cord fabric rubber dam bag and processing technique thereof

A processing technology and cord fabric technology, applied in the field of rubber dam dam bags and their processing technology, can solve the problems of poor water-retaining effect at discounted positions, easy aging and damage of dam bags, stress concentration points of dam bags, etc., and achieve the effect of increasing aesthetics. , The effect of improving the water retaining function and improving the life of the dam bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The cord fabric rubber dam bag of this embodiment is suitable for water-filled rubber dams. The dam height is 1.5m, the dam bottom length is 16.9m, the internal pressure ratio is 1.25, and the slope ratio is 1:0.5. The size of the dam bag in this embodiment is: 6.084m×21.3m, dam bag thickness is 10mm; among them, according to the dam bag size 6.084m×21.3m, width plus 1%-2% shrinkage, length plus 5%-10% shrinkage, the design size is: 6.2m×22.3m.

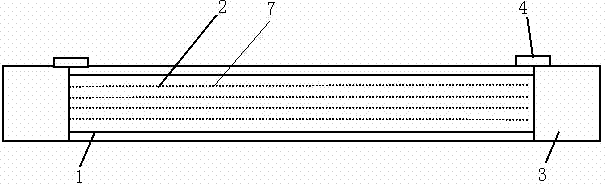

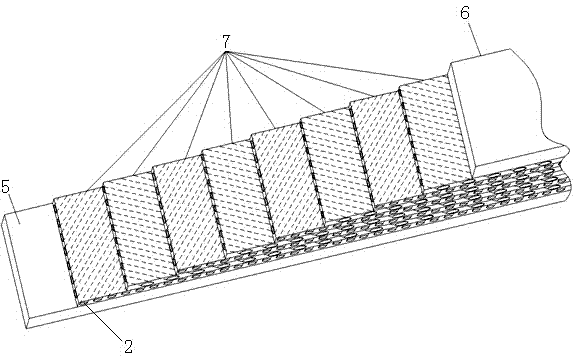

[0032] The cord fabric rubber dam bag includes a dam bag body 1, and the inside of the dam bag body 1 is provided with a multi-layer skeleton layer 7, and each skeleton layer 7 is composed of a plurality of cords 2 spaced apart and arranged obliquely. The cords 2 of the adjacent skeleton layers are symmetrical in slanting directions. The dam bag body 1 and the skeleton layer are combined into one body through a vulcanization process. Both sides of the dam bag body 1 are provided with side glue 3, and the dam bag body 1 and the sid...

Embodiment 2

[0047] The cord fabric rubber dam bag of this embodiment includes a dam bag body 1, and the inside of the dam bag body 1 is provided with a multi-layer skeleton layer 7, and each layer of skeleton layer 7 is composed of a plurality of spaced and inclined curtains. The cord 2 of the adjacent skeleton layer is symmetrical in the direction of the cord 2, the dam bag body 1 and the skeleton layer are combined into one body through a vulcanization process. Both sides of the dam bag body 1 are provided with side glue 3, and the dam bag bag A reinforcing layer 4 is provided between the body 1 and the side glue 3 to combine the two into one body; the inclination angle of the cord 2 is 45 degrees;

[0048] The processing technology of the cord cloth rubber dam bag of this embodiment includes the following processing steps:

[0049] 1). Lay a plurality of cords 2 at intervals and obliquely on the bottom rubber surface 5. After laying the first layer, lay the second layer in a direction symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com