Electromagnetic valve

A solenoid valve and valve body technology, applied in the field of solenoid valves, can solve the problems of increased number of parts and assembly man-hours, cost reduction, difficulties, etc., and achieve the effect of reducing the number of parts and assembly man-hours, cost, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

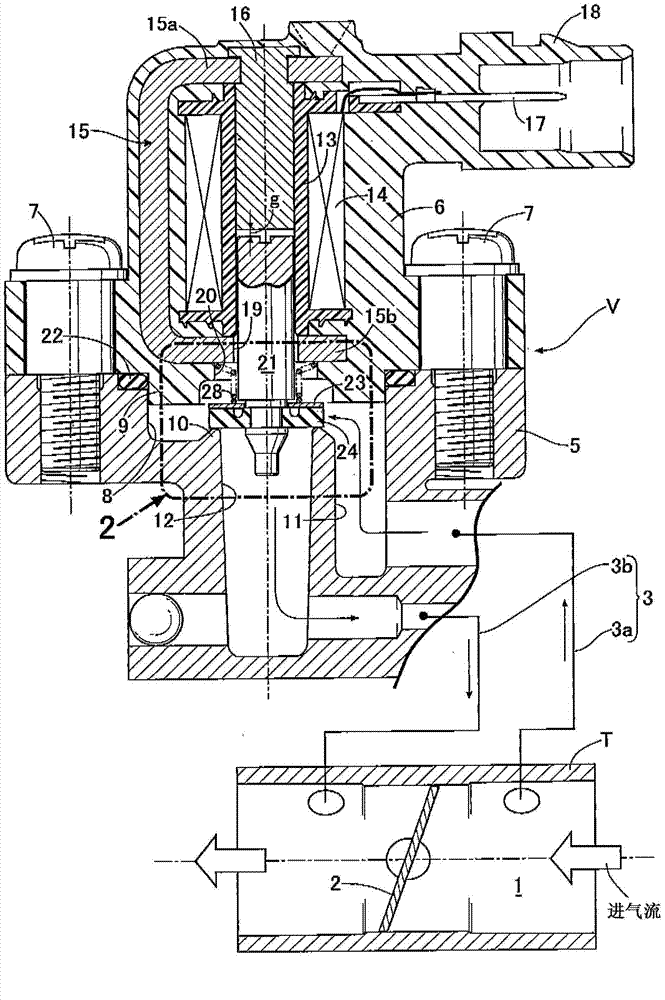

[0034] Embodiments of the present invention will be described below based on the drawings.

[0035] first in figure 1 Among them, a throttle body T installed on an unillustrated engine has an intake port 1 connected to the intake port of the engine, and a butterfly throttle valve that opens and closes the intake port 1 to control the amount of the intake port of the engine. The 2 shafts are supported on the throttle body T. And a bypass 3 is connected to the throttle body T, and the bypass 3 bypasses the throttle body T to communicate between the upstream and downstream parts of the intake passage 1, and the electromagnetic valve of the present invention is installed in the middle of the bypass 3. valve V. This electromagnetic valve V is a normally closed type, and the bypass 3 can be conducted by opening the valve.

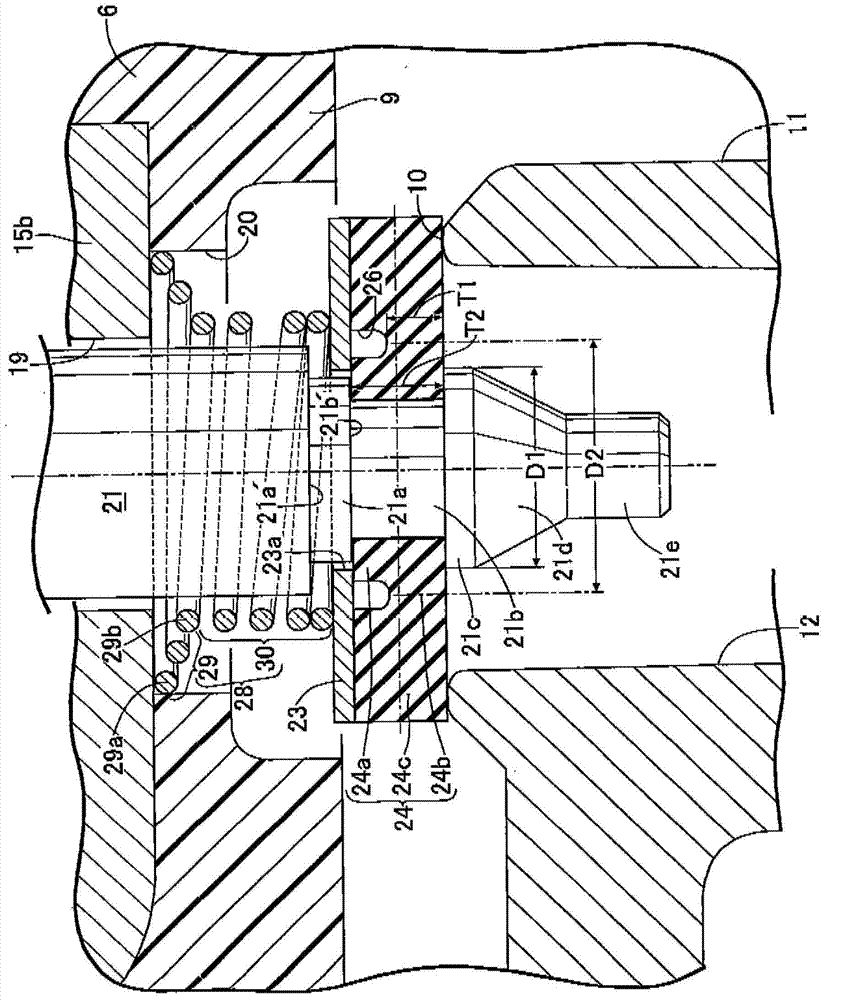

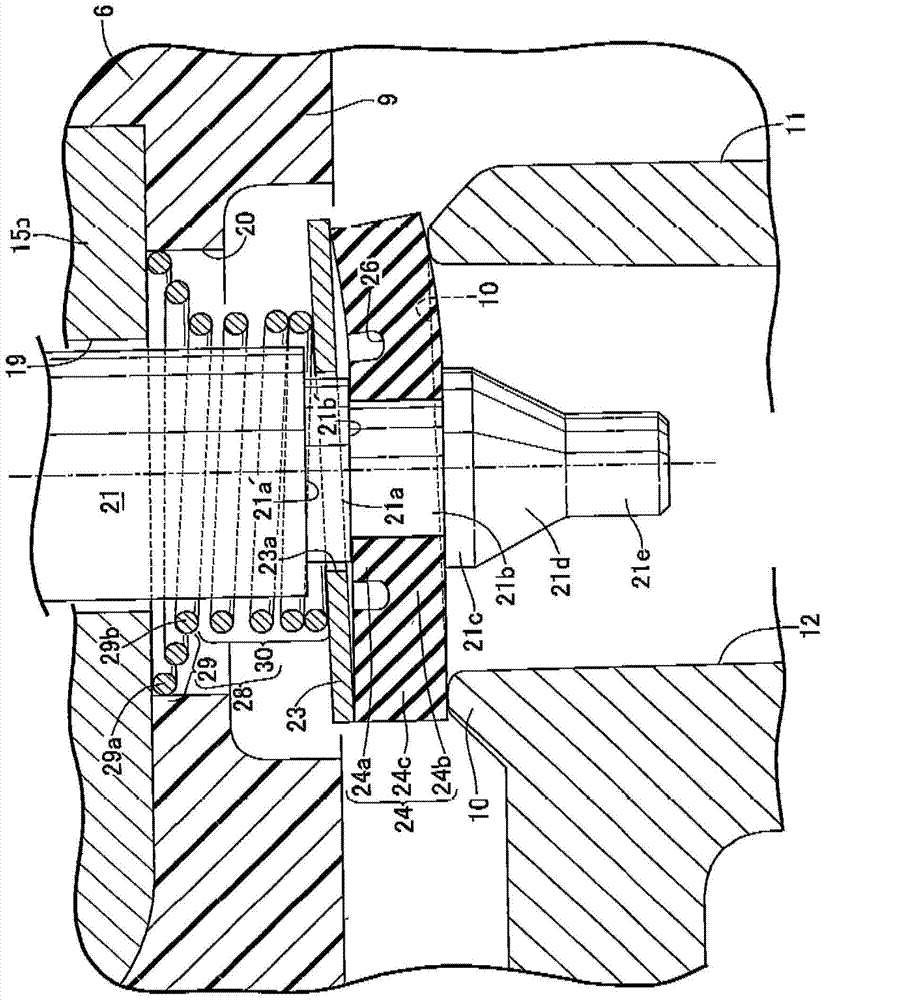

[0036] For the solenoid valve V, use the figure 1 and figure 2 Detailed description.

[0037] The solenoid valve V includes: a valve body 5 supported by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com