Testing device for measuring hydrodynamic gap pressure of bottom plates of plunge pool

A test device and hydrodynamic pressure technology, which is applied in the direction of measuring devices, instruments, suspension and porous material analysis, etc., can solve the problems of not considering the influence of gap hydrodynamic pressure, not being able to simulate the deformation of the concrete floor, and being unable to consider it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

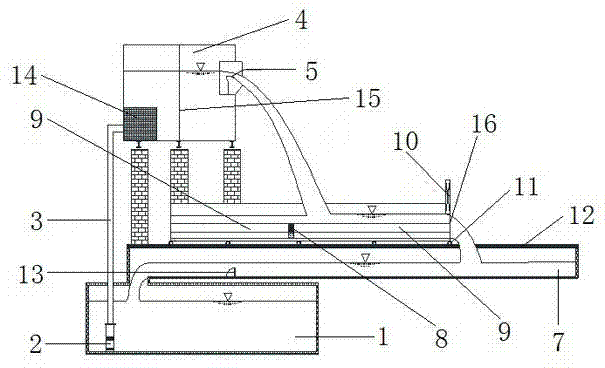

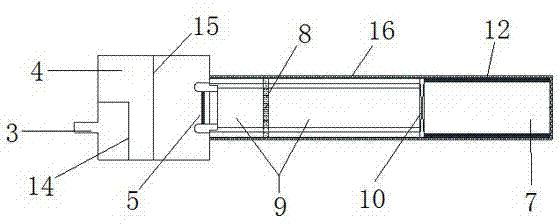

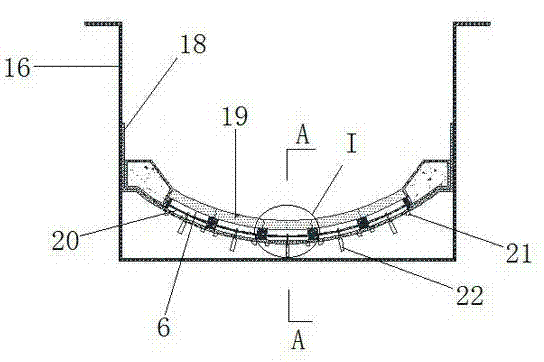

[0038] Such as Figure 1 to Figure 5 As shown, an embodiment of the present invention comprises water cushion pond and five pressure sensors 22, and described water cushion pond comprises casing 16 movable along water flow direction, test section 8 at bottom of casing 16, bottom of casing 16 and Two non-test sections 9 of transverse seams 26 are respectively formed between the upstream and downstream ends of the test section 8, and a liner 18 is provided between the test section 8 and the bottom of the box body 16, and a liner 18 is formed between the liner 18 and the test section 8. The bottom seam 6, the pressure sensor 22 passes through the liner 18 and enters the bottom seam 6, and the five pressure sensors 22 are arranged in the transverse direction. It includes a track 12 arranged along the water flow direction, a pulley 11 is installed at the bottom of the box body 16, and the box body 16 moves on the track 12 through the pulley 11. In order to meet the strength and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com