An adaptive structural plane shear box device

A shear box and structural surface technology, applied in the field of rock mechanics, can solve problems such as excessive frictional resistance on the side of the test piece and the shear box, shear surface breaking or twisting, and test piece lateral shaking, etc., to achieve Reduce the normal direction, reduce the frictional resistance, and avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

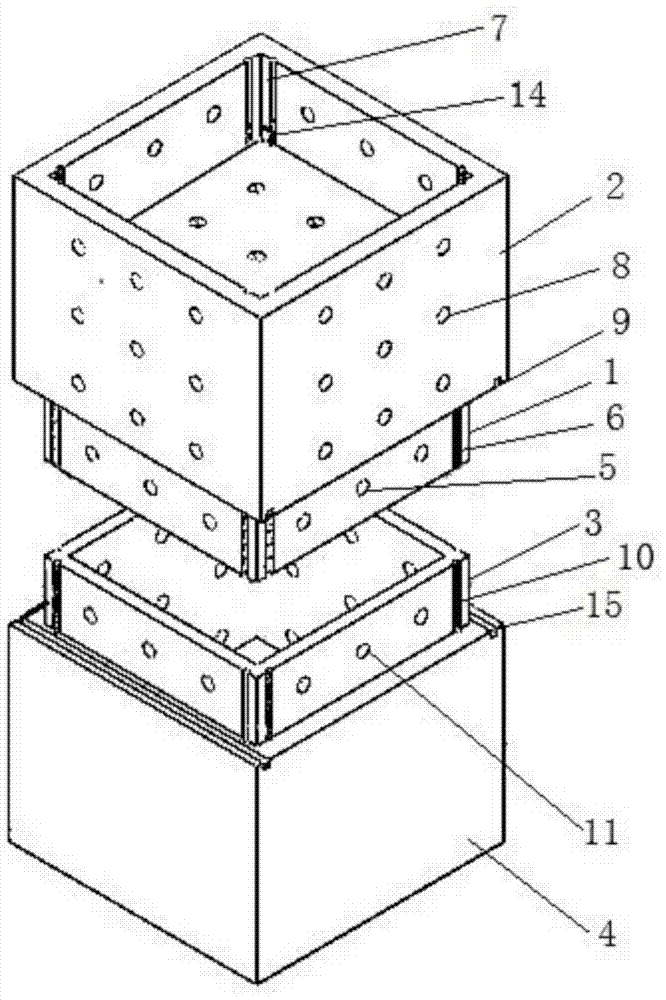

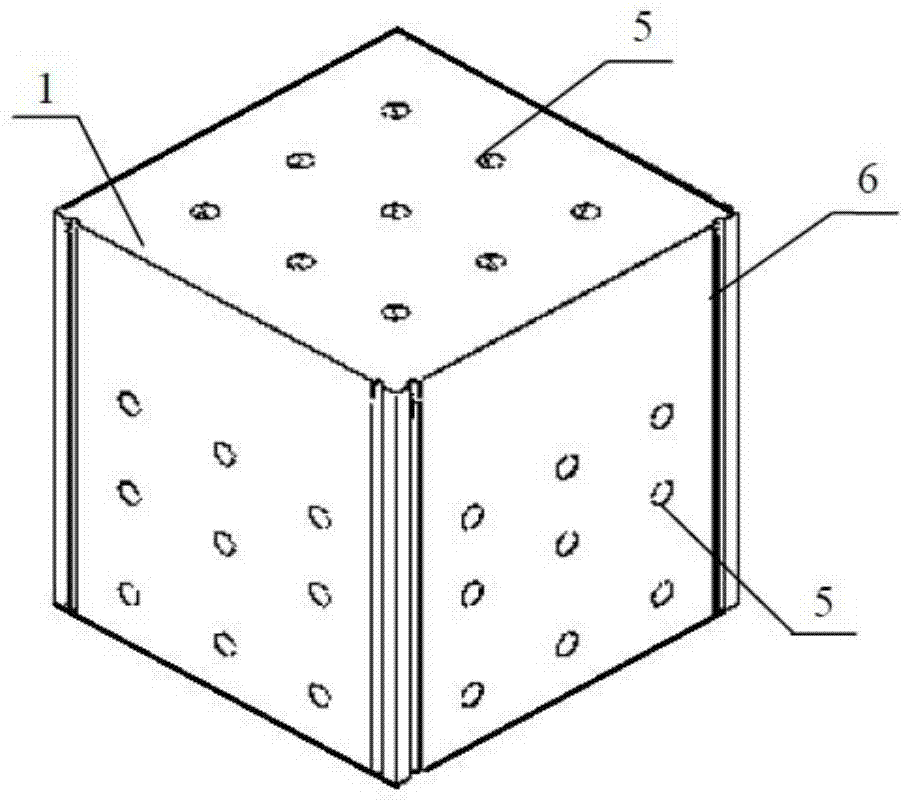

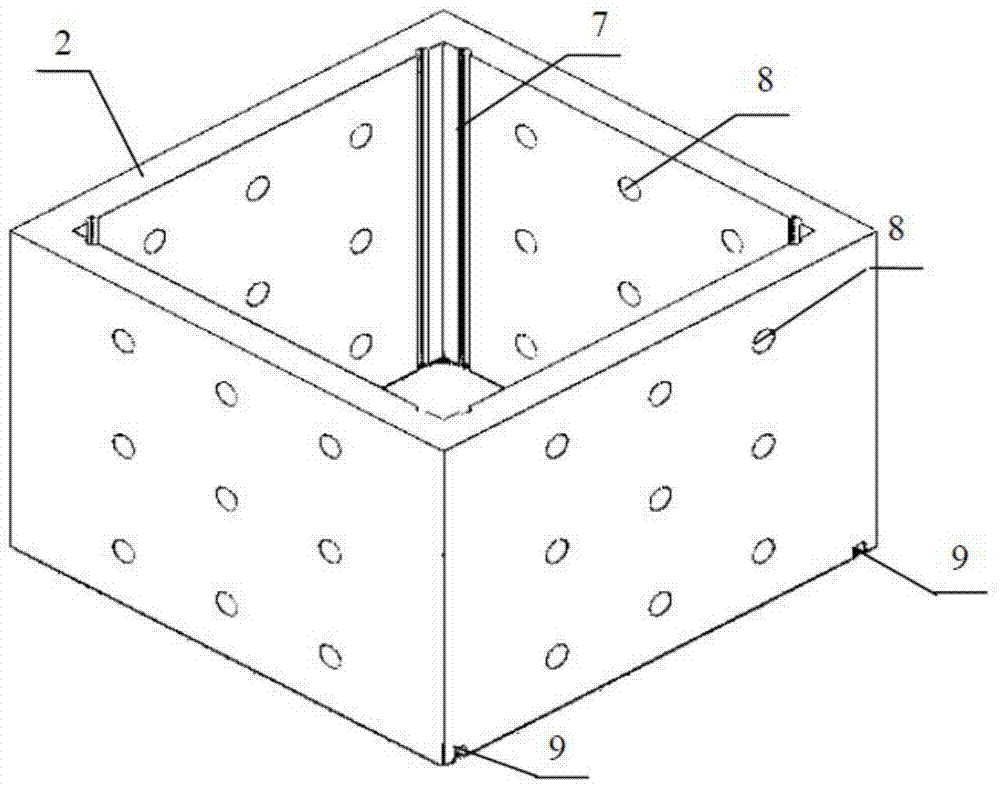

[0026] like Figures 1 to 9 As shown, the self-adaptive structural surface shearing box device of the present invention includes an upper shearing box and a lower shearing box, and the upper shearing box includes an upper shearing box inner box 1 and an upper shearing box outer box 2, and the upper shearing box The inner box 1 is set in the outer box 2 of the upper shear box. The cutting box inner box 3 is set in the lower cutting box outer box 4, and the lower cutting box inner box 3 is provided with a bottom cover. The inner box 1 of the upper shear box is flush with the bottom surface of the outer box 2 of the upper shear box, and the inner box 3 of the lower shear box is flush with the top surfaces of the outer box 4 of the lower shear box. The distance between the outer wall of the inner box 1 of the upper shear box and the inner wall of the outer box 2 of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com