Optical fiber cutting method and sandpaper cutter

A cutting method and cutting knife technology, applied in the direction of optical waveguide coupling, etc., can solve a lot of manpower, material resources and other problems, and achieve the effect of saving equipment costs and cutting costs of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

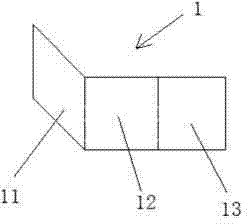

[0017] The present invention will be further described below in conjunction with accompanying drawing.

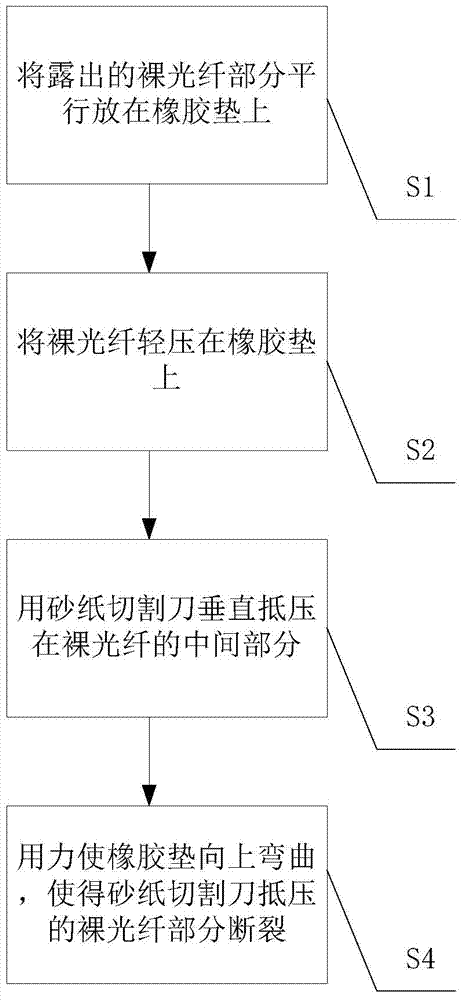

[0018] see figure 1 , one of the optical fiber cutting method of the present invention, comprises the following steps:

[0019] Step S1, placing the exposed bare optical fiber part parallel on the rubber pad, so that both sides of the bare optical fiber and the rubber pad are parallel to each other. In this embodiment, the hardness of the rubber pad is 70 degrees, and the size is 60mm*20mm*4mm.

[0020] Step S2, lightly press the bare optical fiber on the rubber pad with the thumb of the left hand, and press the index finger and middle finger against the bottom of the rubber pad.

[0021] In step S3, the middle part of the bare optical fiber is selected, and the right hand is gently cut vertically with a sandpaper cutter, so as to press against the middle part of the bare optical fiber.

[0022] In step S4, the right hand presses the other side of the bare optical fiber ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap