Structure for end part of vehicle

A vehicle end and vehicle technology, applied to vehicle parts, vehicle safety arrangements, bumpers, etc., can solve the problem of not having to increase the load, achieve the effect of improving shock absorption performance and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]

[0055] A vehicle front portion using a vehicle end structure according to an embodiment of the present invention will be described. In addition, arrow UP shown in each figure indicates the upper side in the vehicle vertical direction, arrow FR indicates the front side in the vehicle front-rear direction, and arrow OUT indicates the outer side in the vehicle width direction.

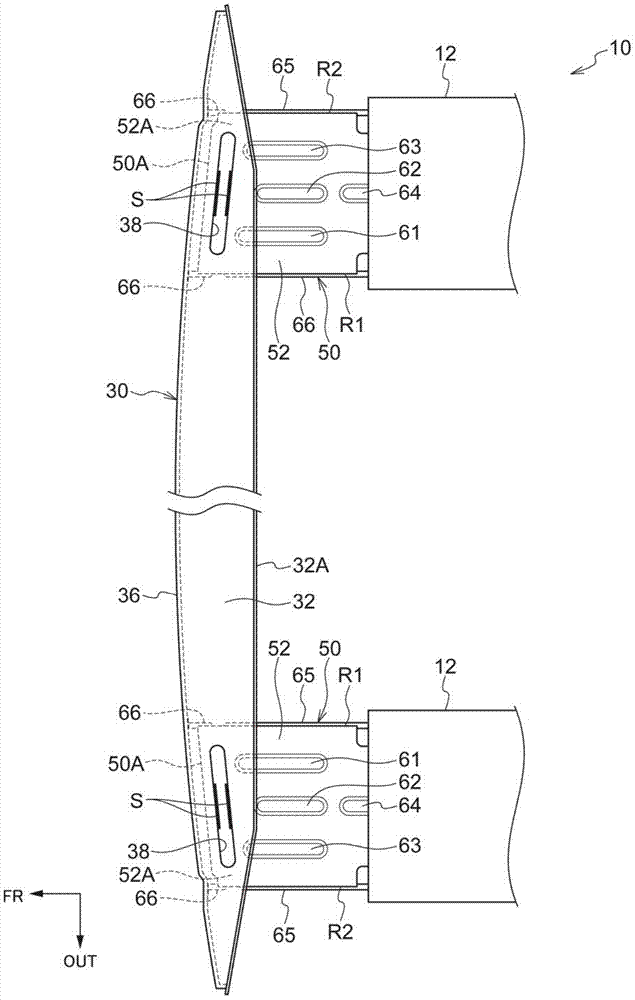

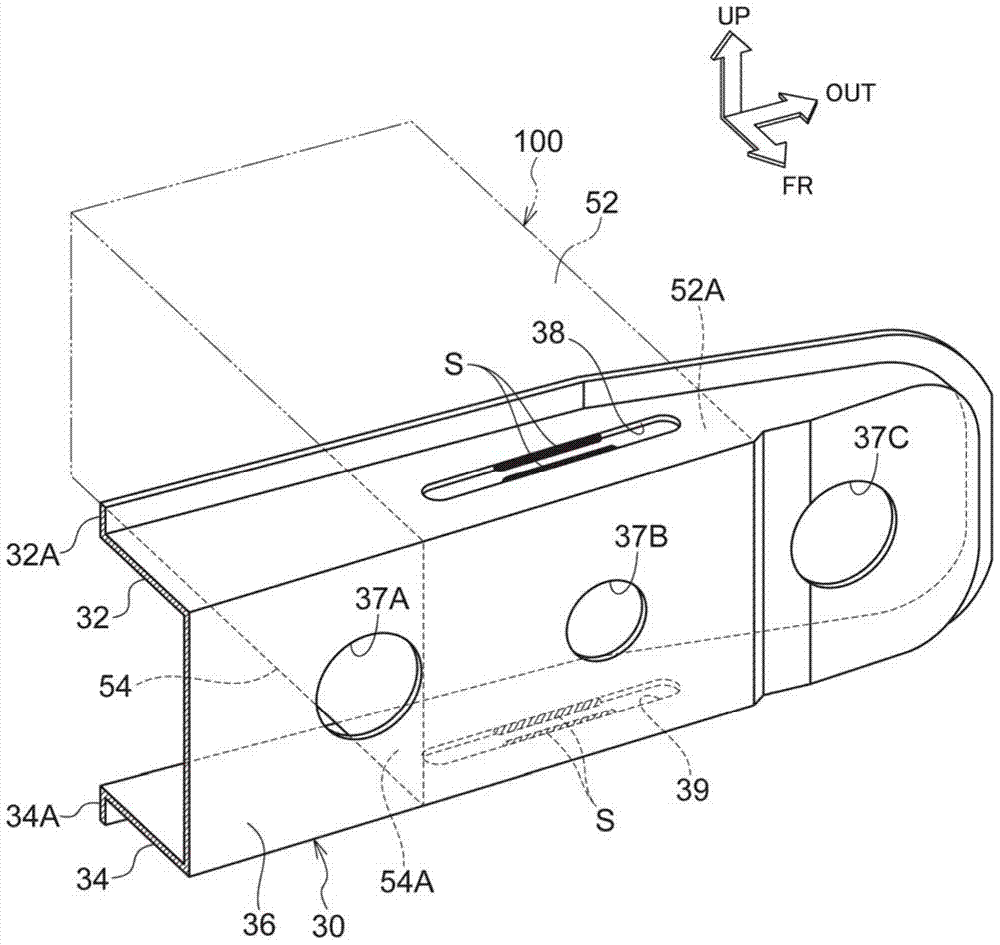

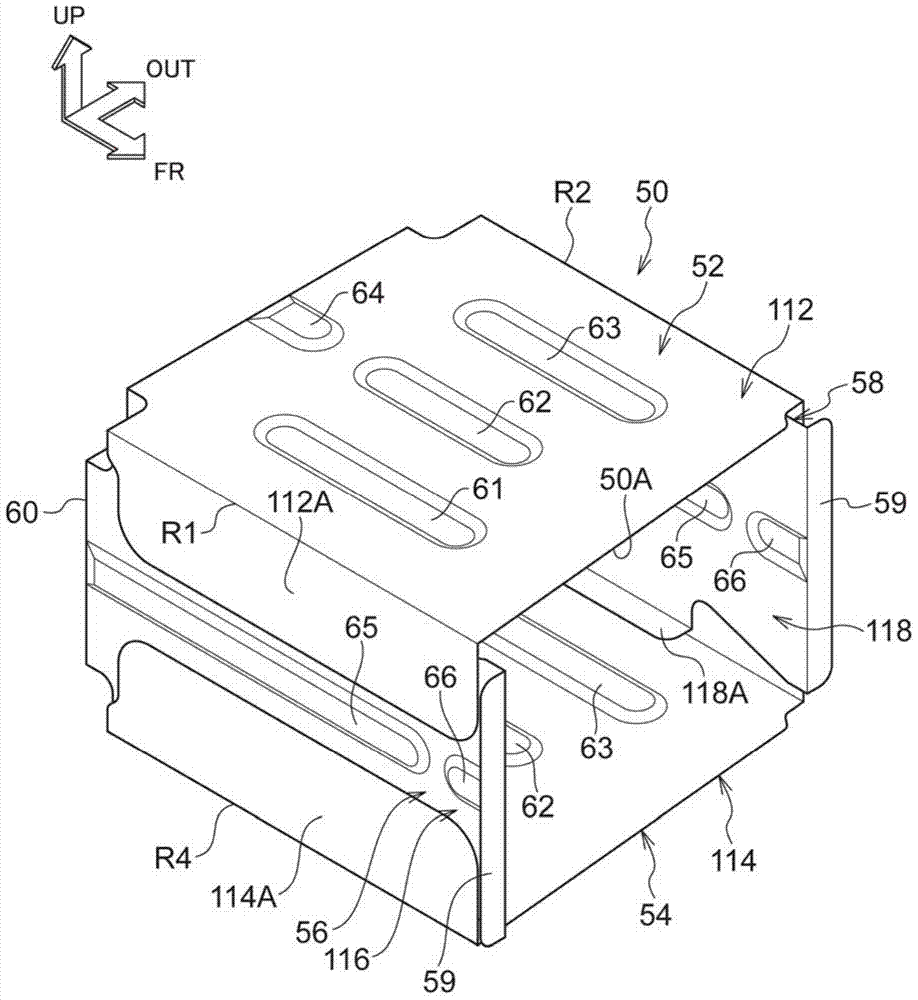

[0056] Such as figure 1 as well as figure 2 As shown, a long bumper reinforcement (front bumper reinforcement) 30 is arranged on the front end portion of the vehicle 10 such that the vehicle width direction is defined as the longitudinal direction. The bumper reinforcement 30 is a high-strength member, and a bumper guard (not shown) is attached to the front surface thereof. Further, elongated side members (front side members) 12 of high-strength components are arranged at lower portions on both sides in the vehicle width direction of the vehicle 10 with the vehicle front-rear direction as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com