Conveyor comprising two helical tracks connected by a bridging track

A screw conveyor and conveyor technology, applied in the field of conveyors, can solve problems such as instability and achieve the effect of reducing the possibility of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

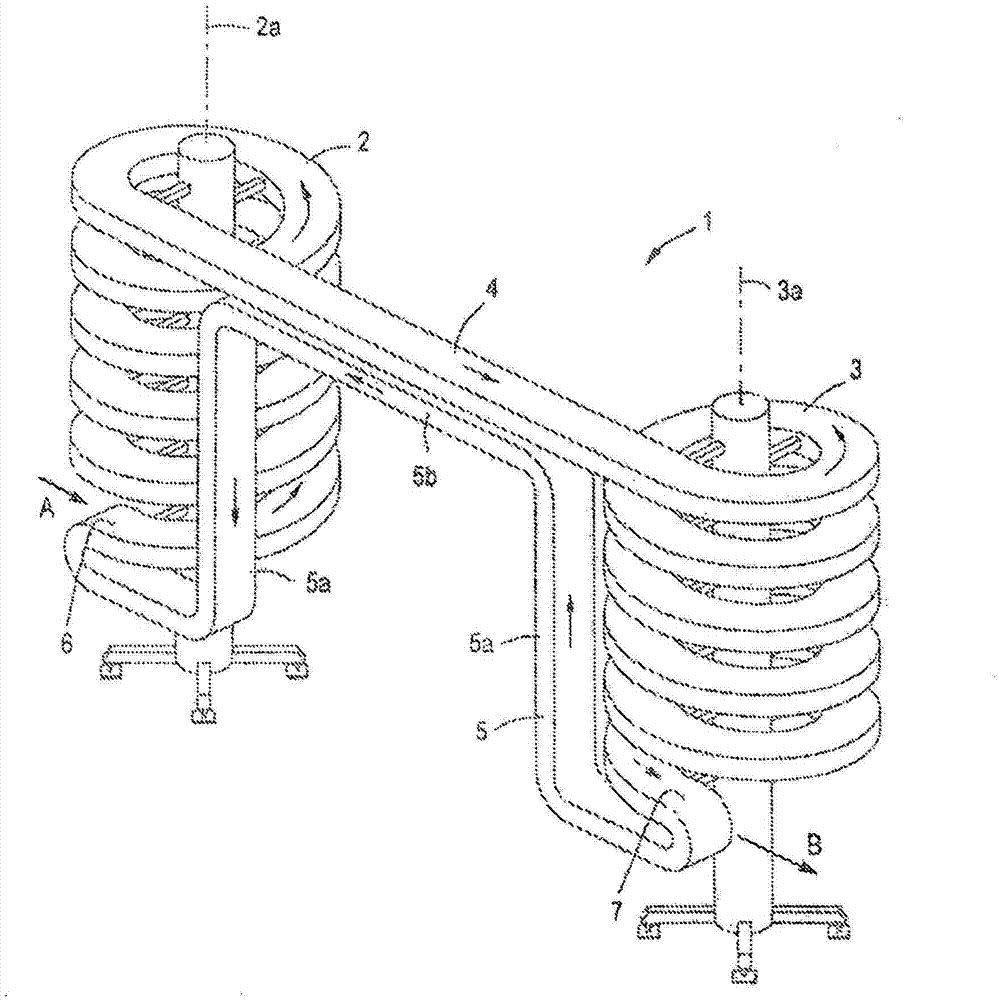

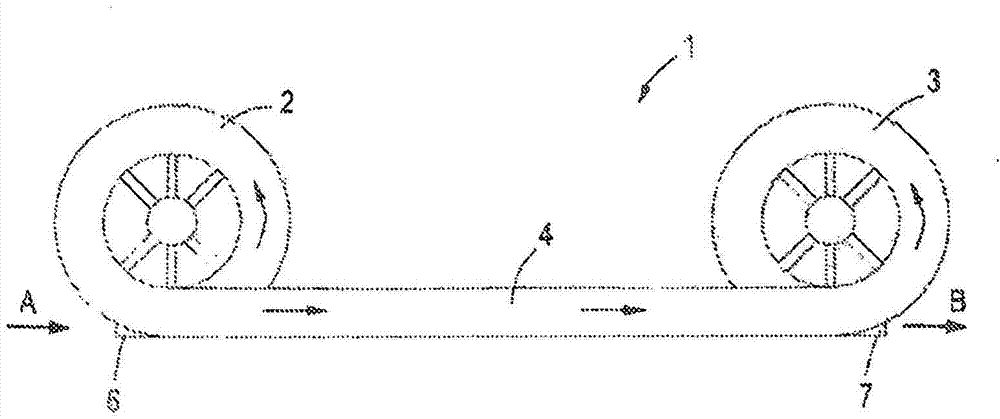

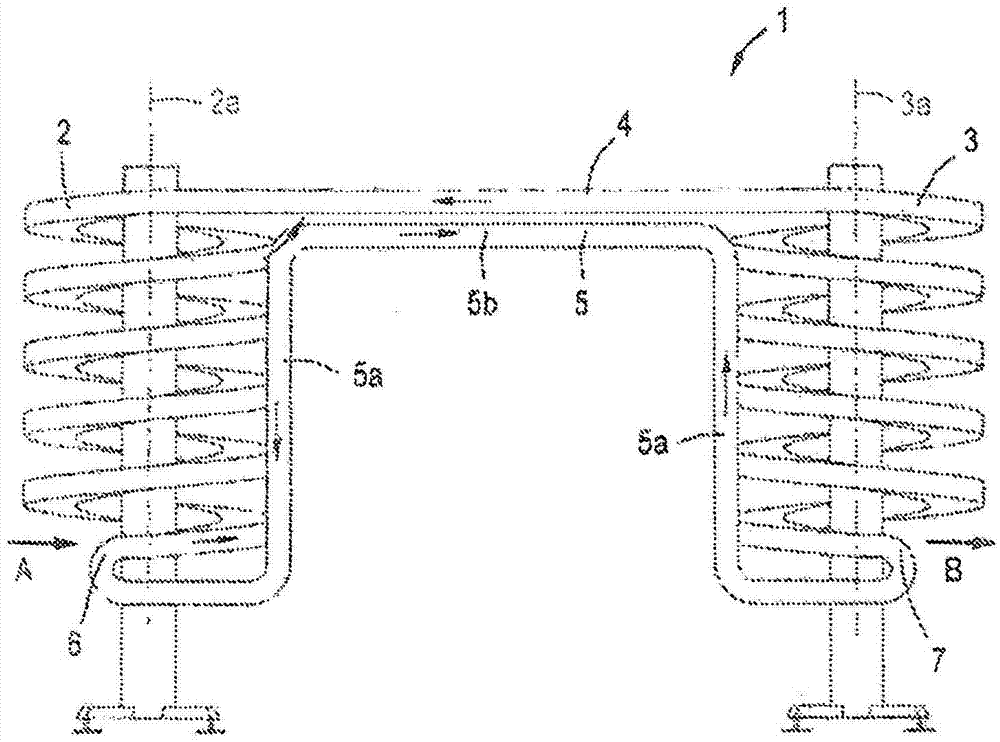

[0027] Figure 1 to Figure 3 A first embodiment of a conveyor 1 according to the invention is shown. The conveyor 1 comprises a first spiral conveyor rail 2 and a second spiral conveyor rail 3 . Both the first and the second spiral conveyor rails 2, 3 have respective vertical center lines 2a, 3a, which in this embodiment extend vertically in parallel. The first and second conveying helical rails 2 , 3 are arranged at a distance from each other such that a channel exists between the first and second conveying helical rails 2 , 3 .

[0028] The conveyor 1 also includes a bridge rail 4 connecting the first spiral conveyor rail 2 and the second spiral conveyor rail 3 . The bridge rail 4 extends between the first and second spiral conveyor rails 2 , 3 . according to Figure 1 to Figure 3 The embodiment of the conveyor has a drivable conveying endless belt, and the conveyor belt follows the first spiral conveying rail 2 upwards, passes the bridge rail 4 from the first spiral con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com