Garbage disposal device with heat dissipation function

A waste disposal device and functional technology, applied in the field of waste disposal devices with heat dissipation function, can solve the problems of reducing work efficiency and wasting manpower, and achieve the effects of improving production efficiency, reliable operation of equipment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below through specific examples.

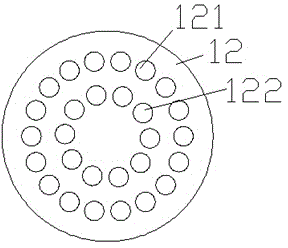

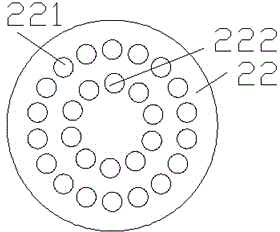

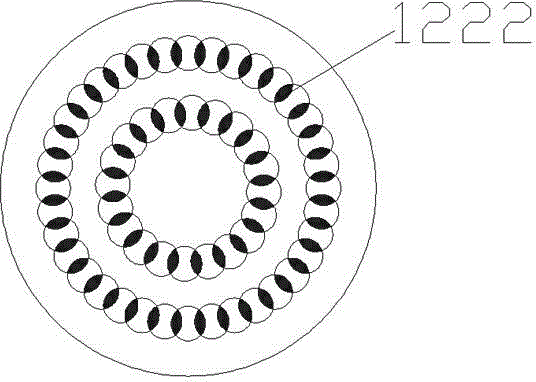

[0019] refer to Figure 1-4 , according to an embodiment, a garbage disposal device with a heat dissipation function is used to pulverize garbage, including a housing 1 with an internal protruding point 10 for breaking the garbage during movement, and the housing 1 The upper sieve plate 12 is fixedly arranged at the bottom, and a central bearing part 13 is arranged at the central part of the upper sieve plate 12. The upper part of the central bearing part 13 is rotatably loaded with a crushing tooth part 2, and the lower part of the central bearing part 13 is rotatably loaded. There is a lower sieve plate 22, a drive motor 4 is provided at the middle of the top of the housing 1, and the surface of the drive motor 4 is coated with cooling fins for absorbing and dissipating the heat generated by the drive motor 4 during operation 3. The bottom of the driving motor 4 is rotationally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com