Conveying mechanism of powder coating booth

A technology of transmission mechanism and powder booth, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of uneven paint powder, stuck conveying chain, etc., and achieve uniform paint powder, guaranteed quality, and easy spraying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

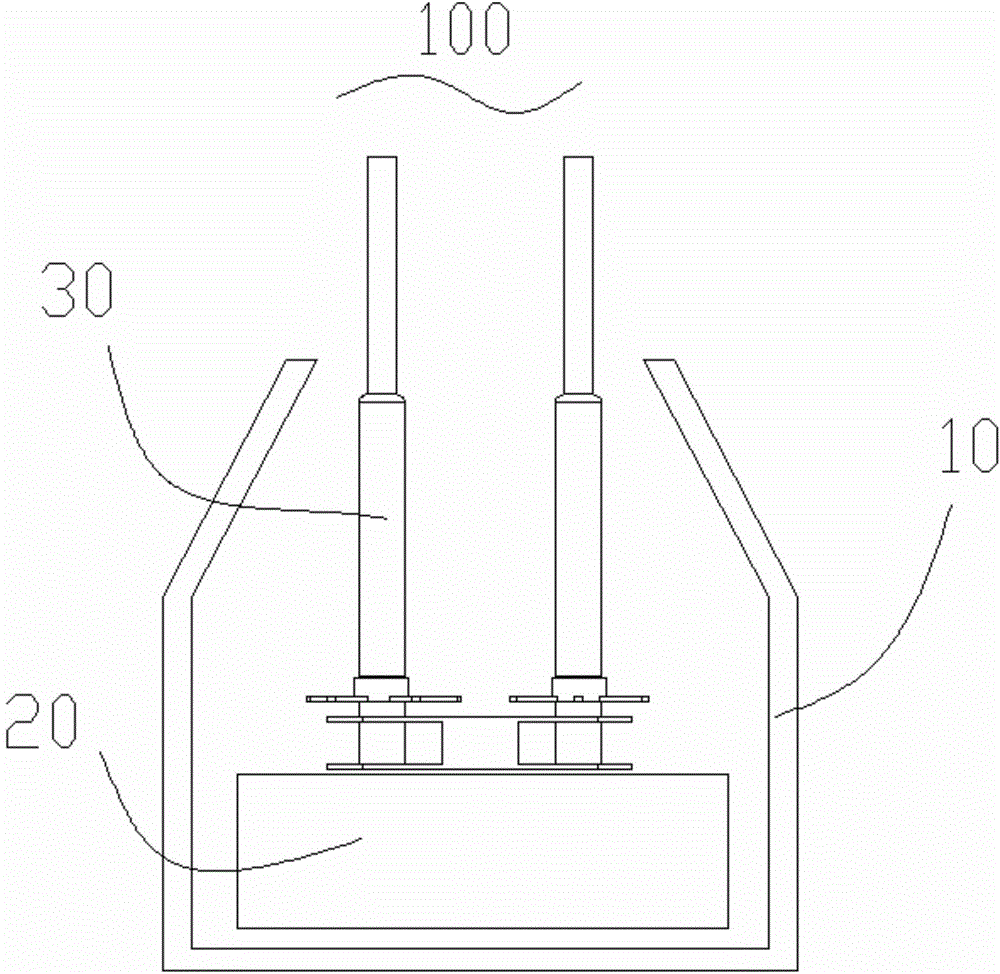

[0022] see figure 1 , The powder room transmission mechanism 100 provided by the preferred embodiment of the present invention includes a protective cover 10 and a conveying chain 20 and a rotating bracket 30 arranged in the protective cover 10 .

[0023] The protective cover 10 is applied in the conveying mechanism 100 of the powder room, and is used to protect the conveying chain 20 and the rotating support 30, so as to prevent the paint powder sprayed on the glass bottle from being embedded in the conveying chain 20 and the rotating support 30. As a result, the conveying chain 20 and the rotating bracket 30 are stuck. Further, the protective cover 10 of this embodiment is bent inwardly relative to the conveying chain 20 from the direction away from the conveying chain 20 .

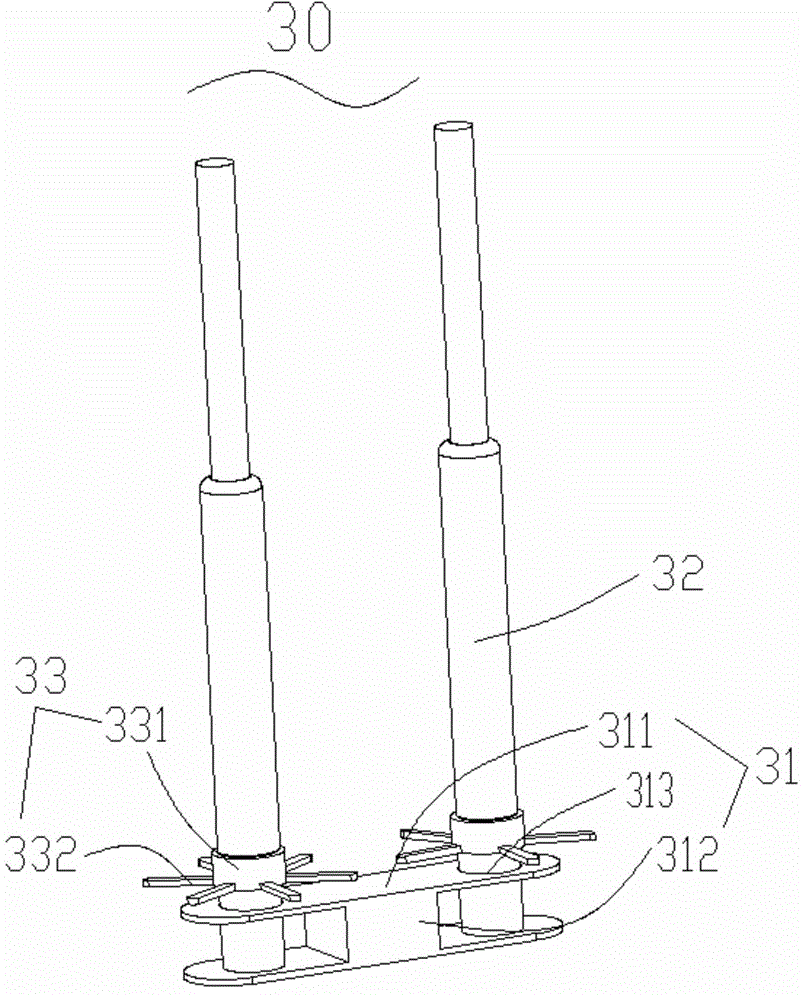

[0024] see figure 2 , the rotating bracket 30 include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap