Bending machine for round tube of scooter

A technology of pipe bending machine and scooter, which is applied in metal processing equipment, feeding device, positioning device, etc., can solve the problems of low pipe bending accuracy, increase shaping process, increase production cost, etc., so as to improve production efficiency and reduce production. The effect of cost and production man-hour reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing:

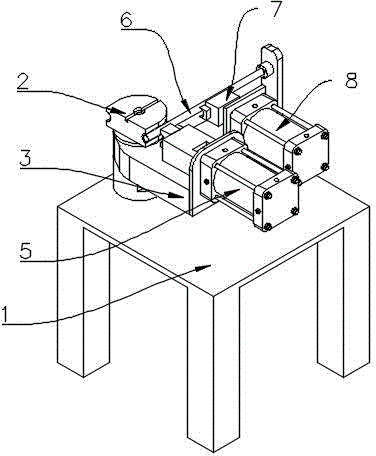

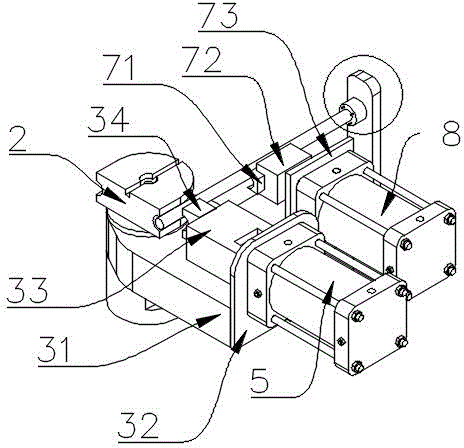

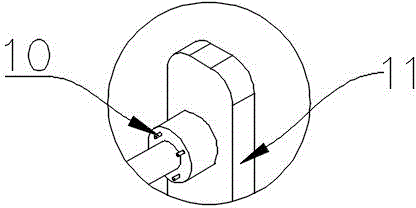

[0017] A round pipe bending machine for a scooter, including a frame 1, characterized in that it also includes a rotating base 2 for rotating the round pipe, a pipe bending mechanism 3 for bending the round pipe, and a compression mechanism for pressing the round pipe 7 and the circular pipe positioning mechanism for positioning the circular pipe; the rotating base 2 is connected with the frame 1, and the rotating base 2 is driven by a motor and gears; the pipe bending mechanism 3 includes a rotating block 31, a pipe bending cylinder fixing seat 32, connecting Seat 33, bent pipe fixed head 34 and bent pipe cylinder 5, bent pipe mechanism 3 is driven by gear rack, rotating block 31 cooperates with rotating base 2, bent pipe cylinder fixing seat 32 is connected with rotating block 31, connecting seat 33 is connected with bent pipe The pipe cylinder 5 is connected, and the elbow fixed head...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap