Rubber dam bag and installation technology thereof

A dam bag and dam technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of short service life, unsightly, poor water retaining effect, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

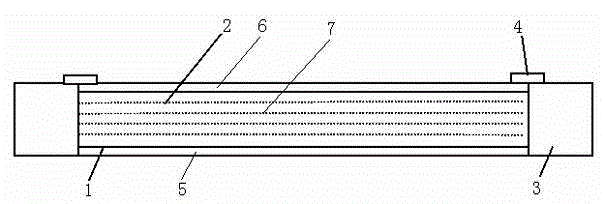

[0049] For the rubber dam bag of this embodiment, refer to the attachment Figure 1-3 The rubber dam bag of this embodiment is suitable for water-filled rubber dams. The dam bag has a height of 1.5m, a bottom length of 16.9m, an internal pressure ratio of 1.25, a slope ratio of 1:0.5, and a dam bag size: 6.084m× 21.3m, dam bag thickness 10mm;

[0050] When designing, according to the dam bag size 6.084m×21.3m, width plus 1%-2% shrinkage, length plus 5%-10% shrinkage, the design size is 6.2m×22.3m.

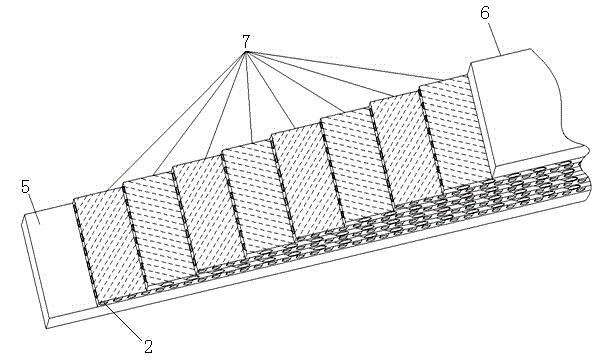

[0051] The rubber dam bag of this embodiment includes a dam bag body 1 composed of a lower rubber surface 5 and an upper rubber surface 6. The special feature is that a multi-layer skeleton layer is provided between the lower rubber surface 5 and the upper rubber surface 6. 7. The skeleton layer 7 includes a plurality of cords 2 spaced apart and arranged obliquely. The cords of the adjacent skeleton layers 7 have symmetrical cords. The lower rubber surface 5, the upper rubber surface 6 ...

Embodiment 2

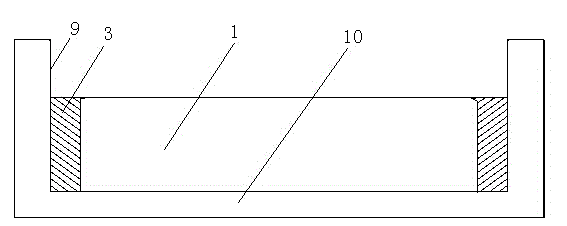

[0071] This embodiment refers to the attached Figure 4-5 The difference between this embodiment and embodiment 1 is that the rubber dam bag includes a dam bag body 1 composed of a lower rubber surface 5 and an upper rubber surface 6. There are multiple rubber dam bags between the lower rubber surface 5 and the upper rubber surface 6. The skeleton layer 7 includes a plurality of cords 2 spaced apart and arranged obliquely. The cords of adjacent skeleton layers 7 have symmetrical cords. The lower rubber surface 5, the upper rubber surface 6 and the skeleton layer 7 are vulcanized Combined as a whole; both sides of the dam bag body 1 are provided with vulcanized airbags 11 integrated with it;

[0072] The installation process is different, the installation process of this embodiment is as follows:

[0073] 1), supplement vulcanization side airbag

[0074] Vulcanize the pre-vulcanized airbag 11 to both sides of the rim of the dam bag body 1;

[0075] 2), installation

[0076] The ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com