Light conduction column capable of conducting multiple LED light sources

A technology of LED light source and light guide column, which is applied in the field of light guide column, and can solve problems such as too dark, uneven light brightness on the light-emitting surface, and excessively bright light-emitting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

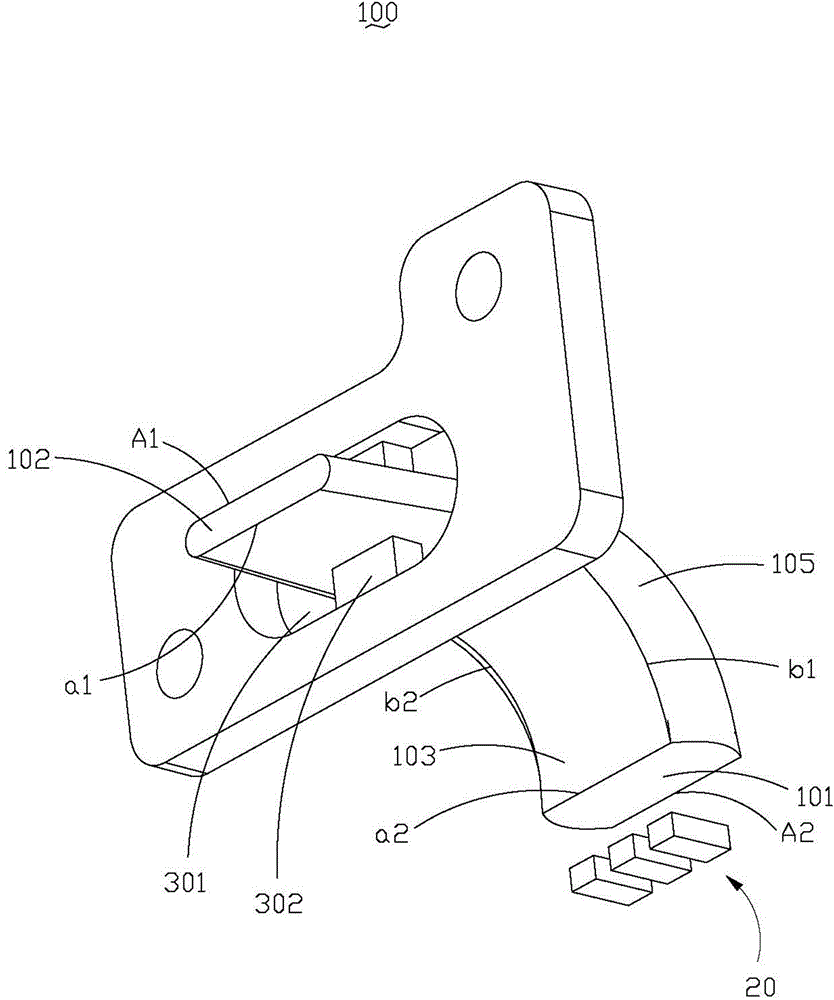

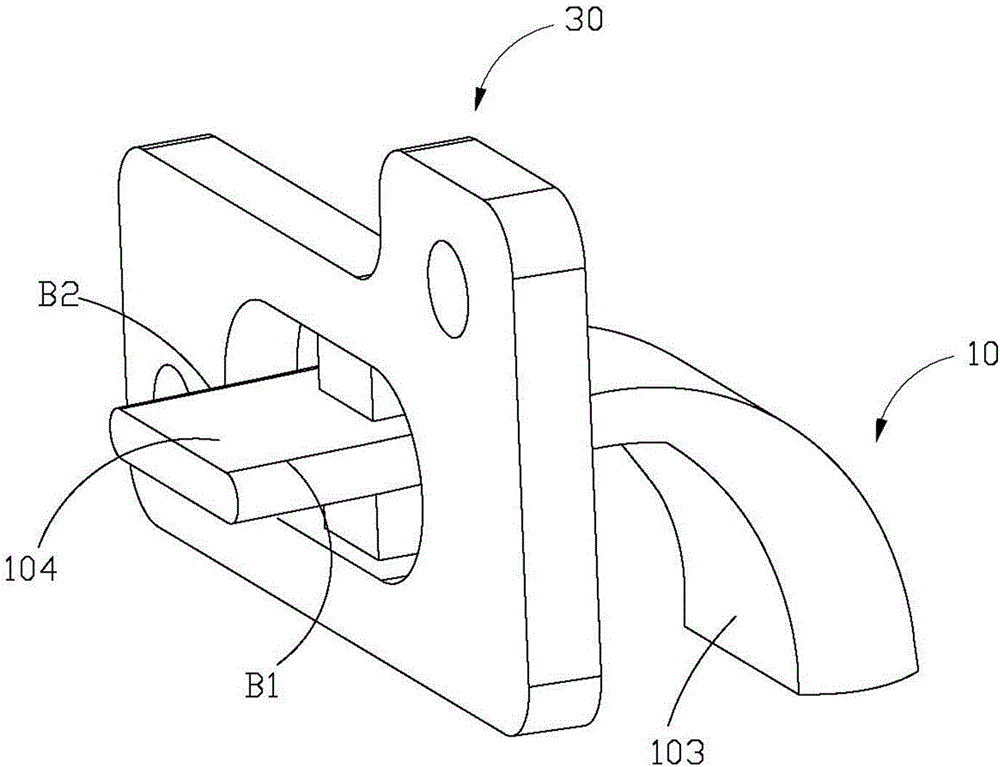

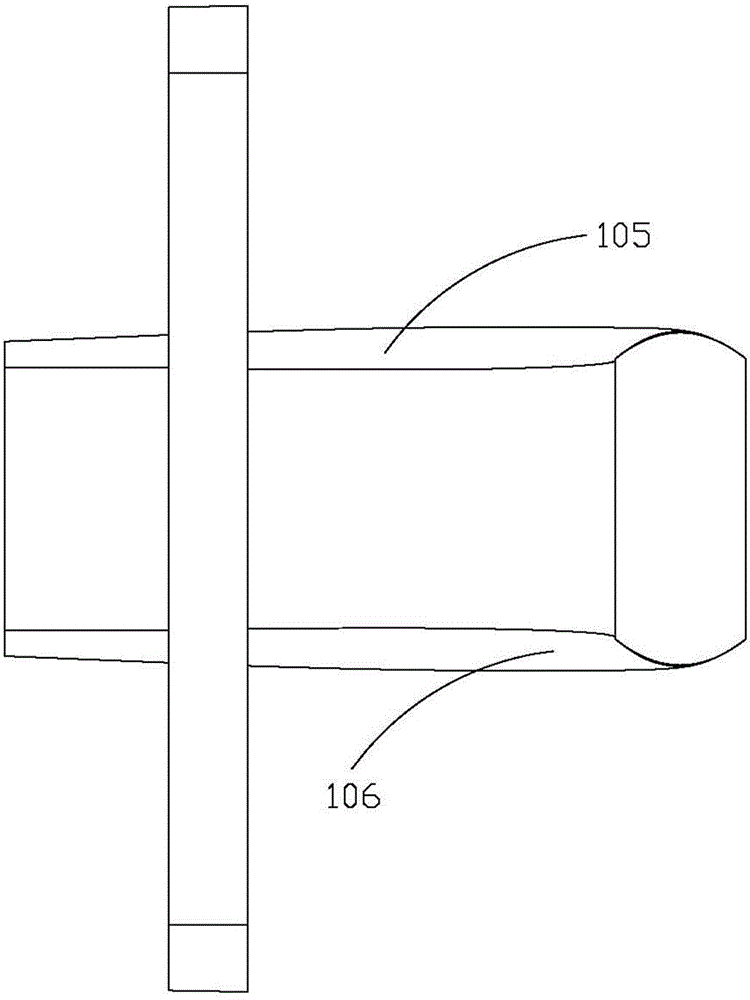

[0026] Such as figure 1 , figure 2 with image 3 As shown, a light source device 100 provided by the present invention includes a light guide rod 10 that can conduct multiple LED light sources, a plurality of LED light sources 20, and a connecting plate 30. The light guide rod 10 is connected to the connecting plate 30, and the light guide rod 10 passes through The connecting plate 30 and the product shell are connected to each other. The light guide rod 10 includes a light incident surface 101, a light exit surface 102, a first surface 103, a second surface 104, a first parabolic side wall 105 and a second parabolic side wall 106. The first surface 103 and the second surface 104 are arranged opposite to each other. parallel. The first parabolic sidewall 105 and the second parabolic sidewall 106 are oppositely disposed and located between the first surface 103 and the second surface 104. The first surface 103, the second surface 104, the first parabolic sidewall 105 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com