Colored filter, manufacturing method thereof and LCD screen containing the optical filter

A color filter, liquid crystal display technology, used in optics, optical components, nonlinear optics, etc., can solve problems such as poor contrast characteristics and color characteristics, and achieve balanced transmission and reflection, low cost, and display. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

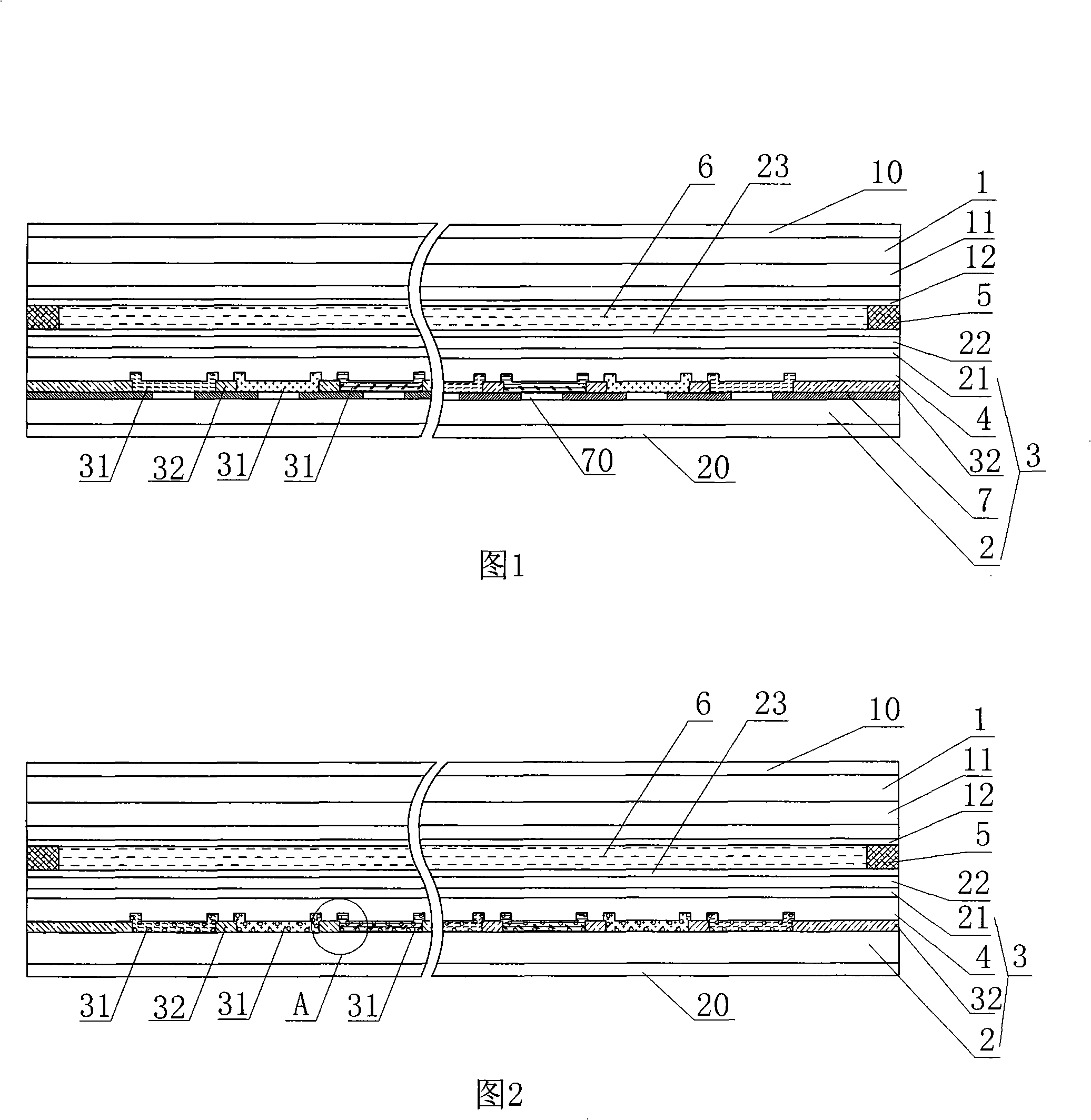

[0036] See Figure 2 and image 3 , a transflective color liquid crystal display of the present invention, an upper polarizer 10, an upper glass substrate 1, an upper transparent conductive film 11, an upper liquid crystal alignment layer 12, a liquid crystal 6, a lower liquid crystal alignment layer 22, a color filter 3, Lower polarizer 20.

[0037] The upper polarizer 10 is pasted on the upper surface of the upper glass substrate 1, and the lower surface of the upper glass substrate 1 is plated with an upper transparent conductive film 11, and the upper transparent conductive film 11 is etched with images to be displayed. The upper transparent conductive film 11 is coated with an upper liquid crystal alignment layer 12;

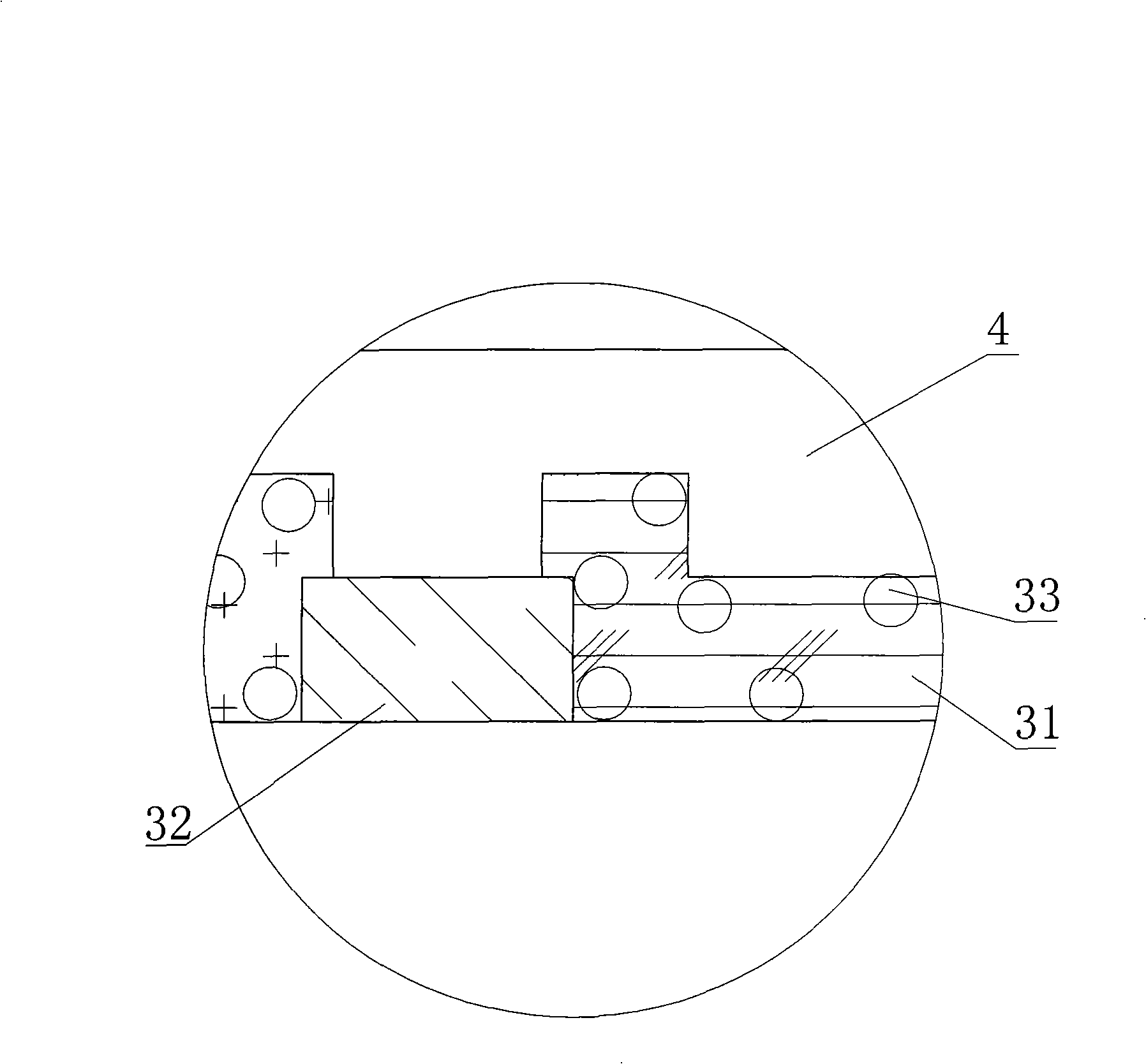

[0038]The color filter 3 includes a lower transparent conductive film 21 , a transparent insulating layer 4 , a color filter film 31 , a black matrix 32 , and a lower glass substrate 2 . The lower polarizer 20 is pasted on the lower surface of the lower gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com