Uniform heating large microwave oven

A large-scale, microwave technology, used in heating methods, electric heating fuels, lighting and heating equipment, etc., can solve the problems of limited utilization of microwave ovens, decline in product and qualified rate, affecting product production efficiency, etc., to improve space utilization. rate, improve quality, novel and unique effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

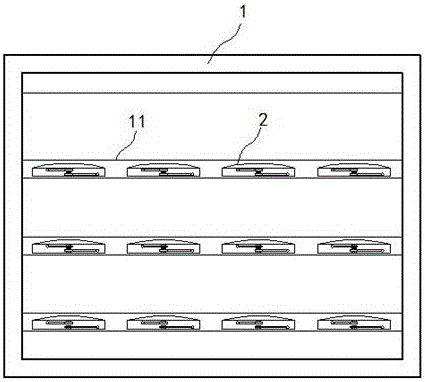

[0017] exist figure 1 , figure 2 In the shown embodiment, the large-scale microwave oven with uniform heating includes a furnace body 1 and a closed door;

[0018] In the furnace body 1, horizontal liners 11 are equidistantly clamped, and each liner 11 includes an upper plate and a lower plate, and a reflector 2 is movably placed between the upper plate and the lower plate; The outer surface of disc 2 is coated with a reflective coating;

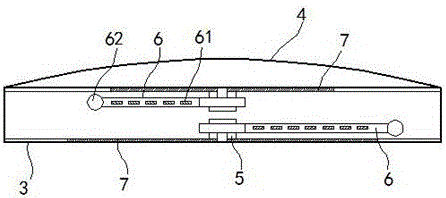

[0019] The reflective disk 2 includes a reflective shell 3 and a reflective mirror 4, the reflective mirror 4 is installed on the upper surface of the reflective shell 3, and the reflective mirror 4 is in a convex arc shape; the top plate and the bottom plate inside the reflective shell 3 A clockwork disc 5 is installed, and the two clockwork discs 5 are coaxially opposite, and the central axis of the clockwork disc 5 is perpendicular to the bottom plate of the reflective shell 3; the tightening ends of the two clockwork discs 5 expose th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com