A combined light-cutting structure, led lamp and led lamp tube

A combined, LED light source technology, applied in the field of lighting, can solve problems such as high cost and limit the choice of manufacturers, and achieve the effects of suppressing glare, improving lighting comfort, and improving light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

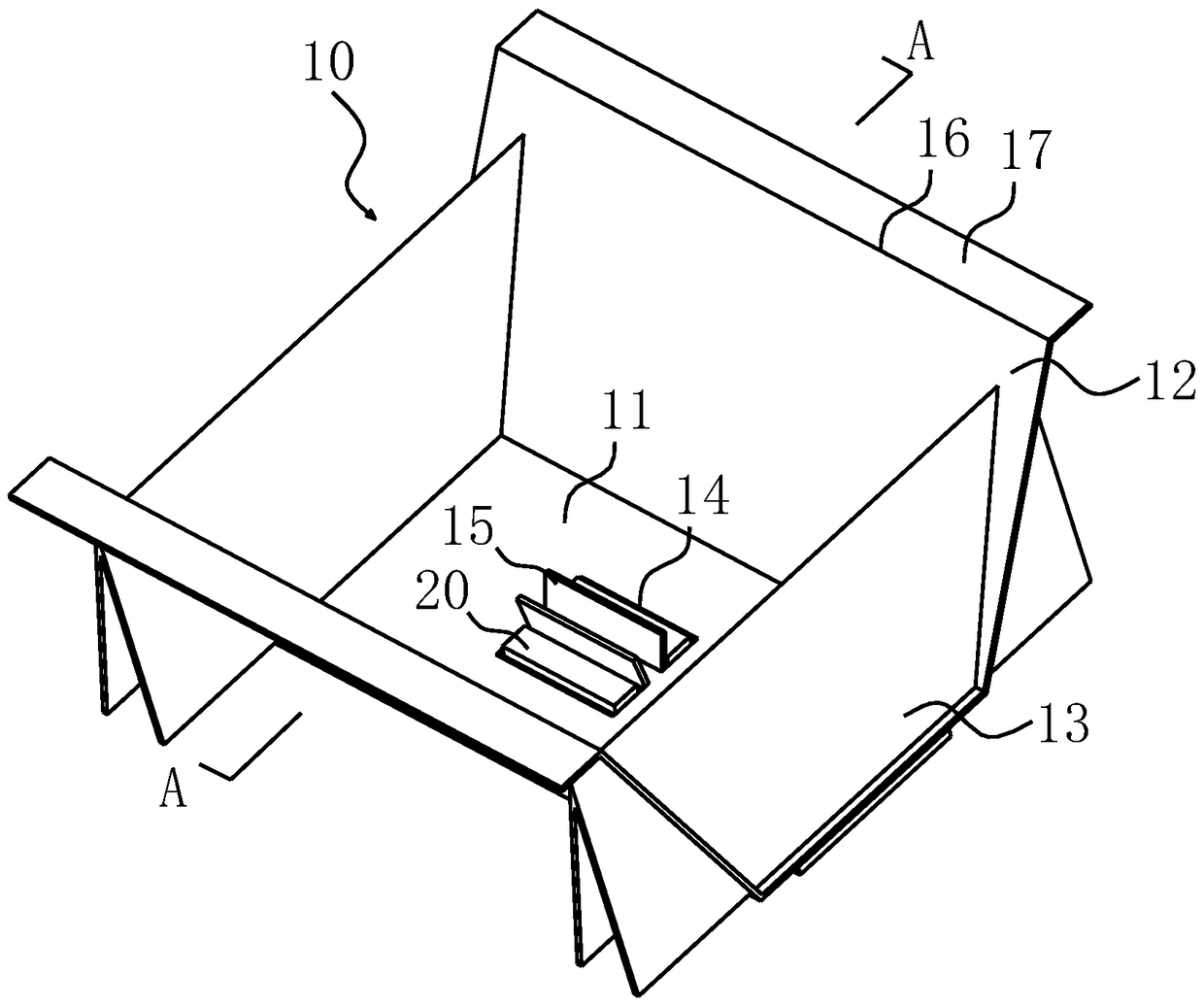

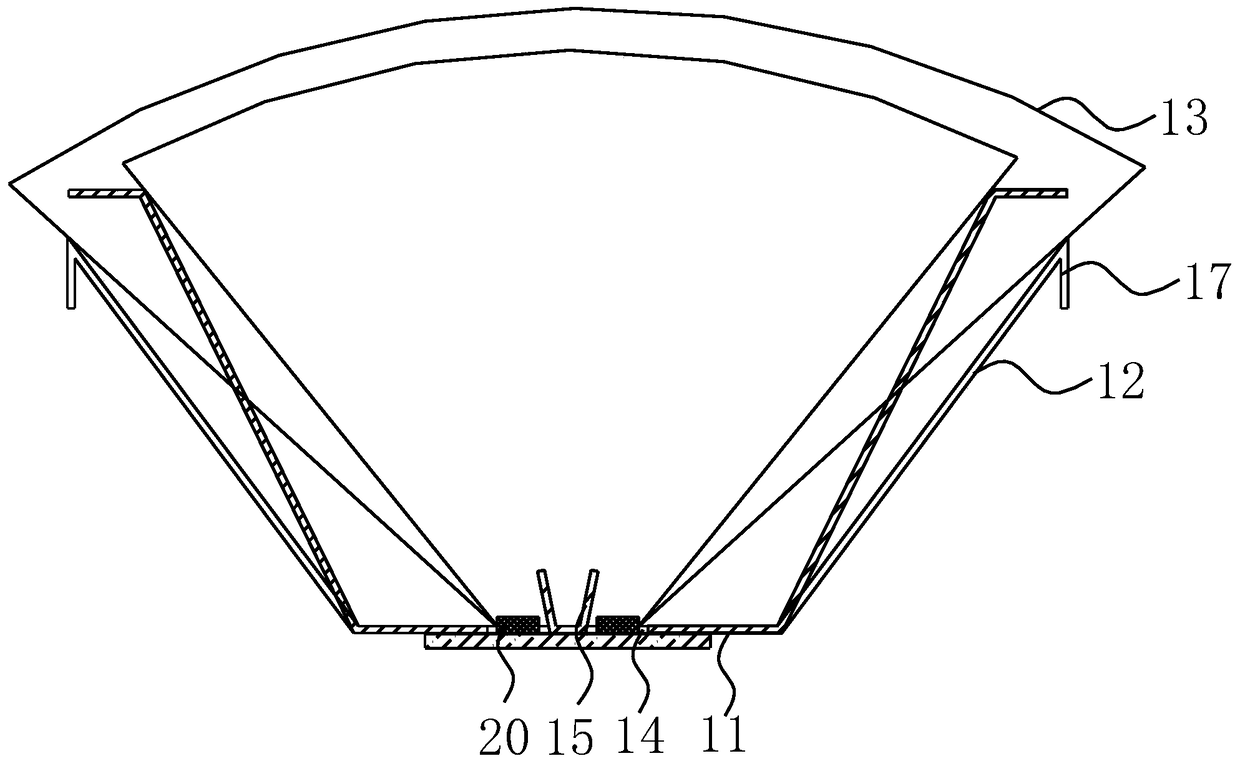

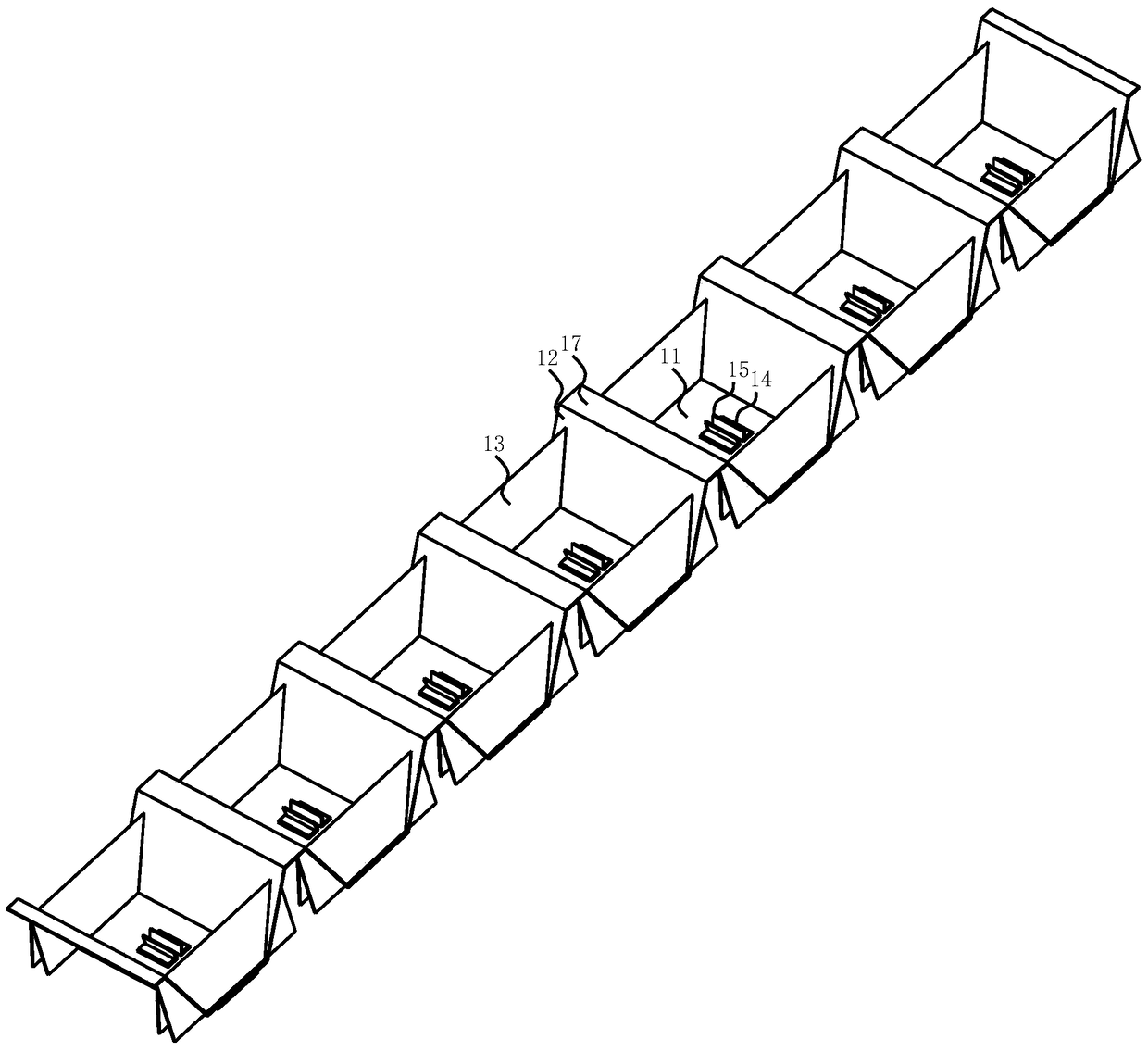

[0047] Such as figure 1 , 2 As shown, the combined light-cutting structure of this embodiment may generally include a light source cavity 10, the light source cavity 10 is composed of a bottom plate 11 and two holes respectively arranged on opposite sides of the bottom plate 11 for controlling the direct light angle of the LED light source. The side plate 12 and the partition plate 13 are formed; the side plate 12 and the partition plate 13 are in contact with each other through adjacent sides, and their bottom edges are respectively close to or attached to or directly connected with the bottom plate 11; the bottom plate 11 is provided with LED light source The exposed light source reserved hole 14 is obliquely provided with a shading baffle 15 on the side of the light source reserved hole 14, and the shading baffle 15 is used to further adjust the direct light emitted by the LED light source in the light source reserved hole 14. Angle; the area of the shading baffle 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com