Liquid storage tank material level indicating device with signal long-distance transmission as well as design method and liquid level calculating method of device

A technology for indicating devices and liquid storage tanks, which is applied in the direction of buoy liquid level indicators, etc., can solve the problems of inconvenient all-weather on-site observation, discontinuous signals, and unintuitive indications, and achieve good energy-saving effects, intuitive indications, and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

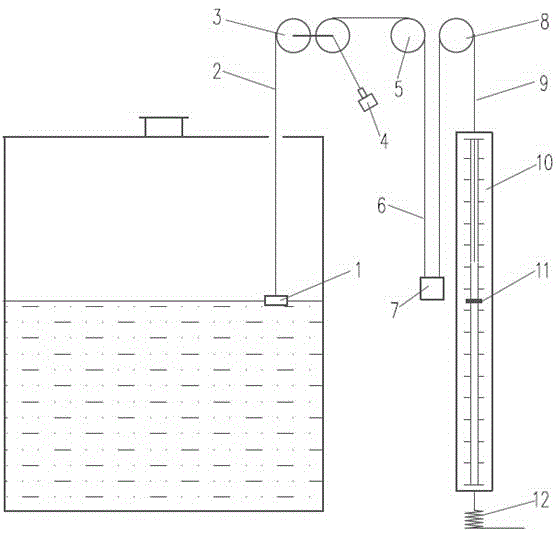

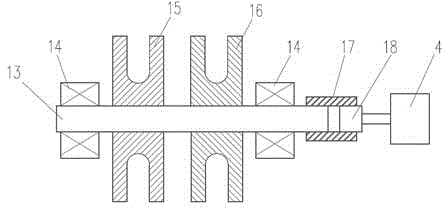

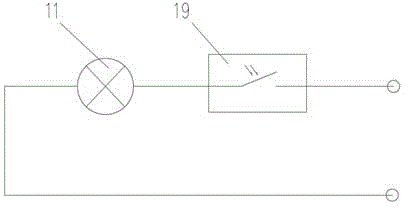

[0036] Embodiment 1: as Figure 1-3 As shown, a liquid storage tank level indicator device with signal remote transmission, including float 1, soft rope A2, double pulley 3, potentiometer 4, fixed pulley 5, soft rope B6, counterweight 7, reversing fixed Pulley 8, soft rope C9, scale 10, indicating light rod 11, flexible wire 12, pulley shaft 13, bearing 14, driving wheel 15, driven wheel 16, coupling tube 17, potentiometer bushing 18, photoelectric switch 19;

[0037] The flexible rope A2 connects the driving pulley 15 of the float 1 and the double-wheel pulley 3, and the soft rope B6 connects the driven pulley 16 and the counterweight 7 of the double-wheel pulley 3, and bridges over the fixed pulley 5 in the middle;

[0038] The driving wheel 15 and the driven wheel 16 of the double-wheel pulley 3 are fixed on the same pulley shaft 13, and the pulley shaft 13 is installed on two bearings 14, and one end of the pulley shaft 13 is connected to the potentiometer bushing 18 through...

Embodiment 2

[0053] Embodiment 2: as Figure 1-3 As shown, a liquid storage tank level indicator device with signal remote transmission, including float 1, soft rope A2, double pulley 3, potentiometer 4, fixed pulley 5, soft rope B6, counterweight 7, reversing fixed Pulley 8, soft rope C9, scale 10, indicating light rod 11, flexible wire 12, pulley shaft 13, bearing 14, driving wheel 15, driven wheel 16, coupling tube 17, potentiometer bushing 18, photoelectric switch 19;

[0054] The flexible rope A2 connects the driving pulley 15 of the float 1 and the double-wheel pulley 3, and the soft rope B6 connects the driven pulley 16 and the counterweight 7 of the double-wheel pulley 3, and bridges over the fixed pulley 5 in the middle;

[0055] The driving wheel 15 and the driven wheel 16 of the double-wheel pulley 3 are fixed on the same pulley shaft 13, and the pulley shaft 13 is installed on two bearings 14, and one end of the pulley shaft 13 is connected to the potentiometer bushing 18 throu...

Embodiment 3

[0068] Embodiment 3: as Figure 1-3 As shown, a liquid storage tank level indicator device with signal remote transmission, including float 1, soft rope A2, double pulley 3, potentiometer 4, fixed pulley 5, soft rope B6, counterweight 7, reversing fixed Pulley 8, soft rope C9, scale 10, indicating light rod 11, flexible wire 12, pulley shaft 13, bearing 14, driving wheel 15, driven wheel 16, coupling tube 17, potentiometer bushing 18, photoelectric switch 19;

[0069] The flexible rope A2 connects the driving pulley 15 of the float 1 and the double-wheel pulley 3, and the soft rope B6 connects the driven pulley 16 and the counterweight 7 of the double-wheel pulley 3, and bridges over the fixed pulley 5 in the middle;

[0070] The driving wheel 15 and the driven wheel 16 of the double-wheel pulley 3 are fixed on the same pulley shaft 13, and the pulley shaft 13 is installed on two bearings 14, and one end of the pulley shaft 13 is connected to the potentiometer bushing 18 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com