Smoke density test device

A technology for testing device and smoke density, which is applied in measurement devices, specific gravity measurement, instruments, etc., can solve the problems that the combustion test method cannot fully describe the combustion performance and the combustion behavior of flame retardant materials is complicated, and achieves low cost, good combustion behavior, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing.

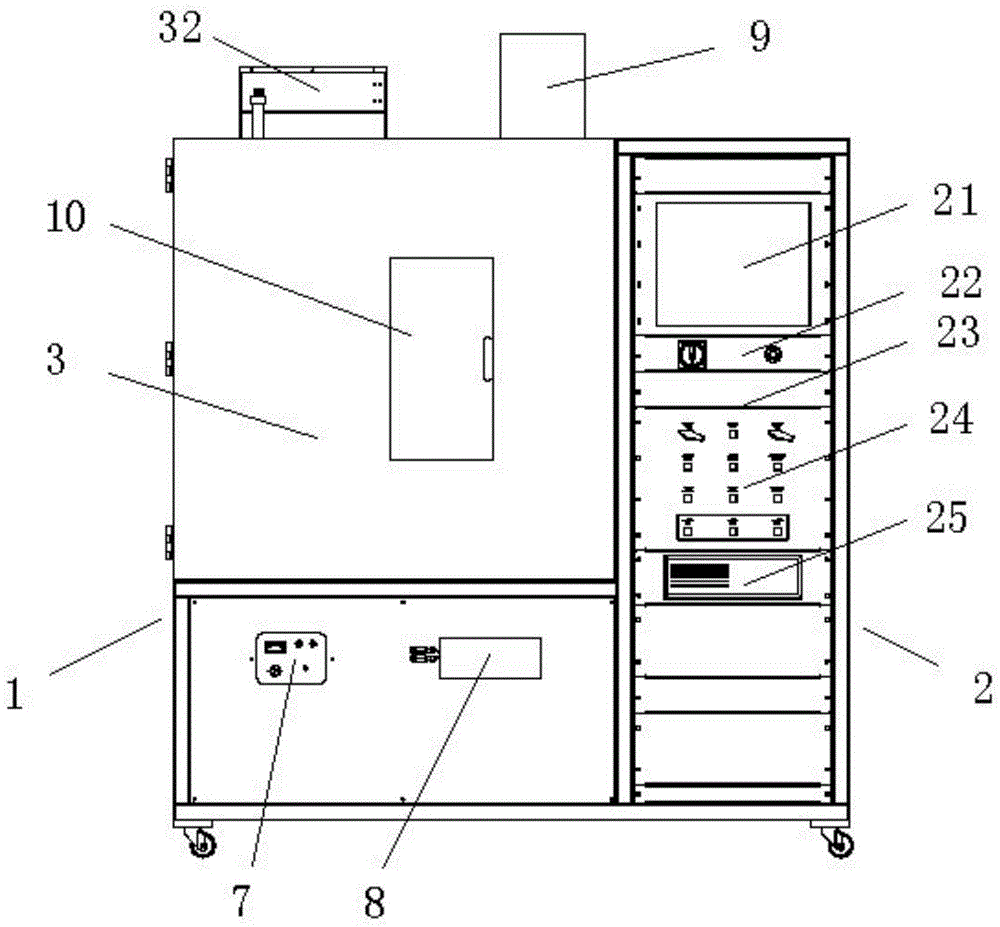

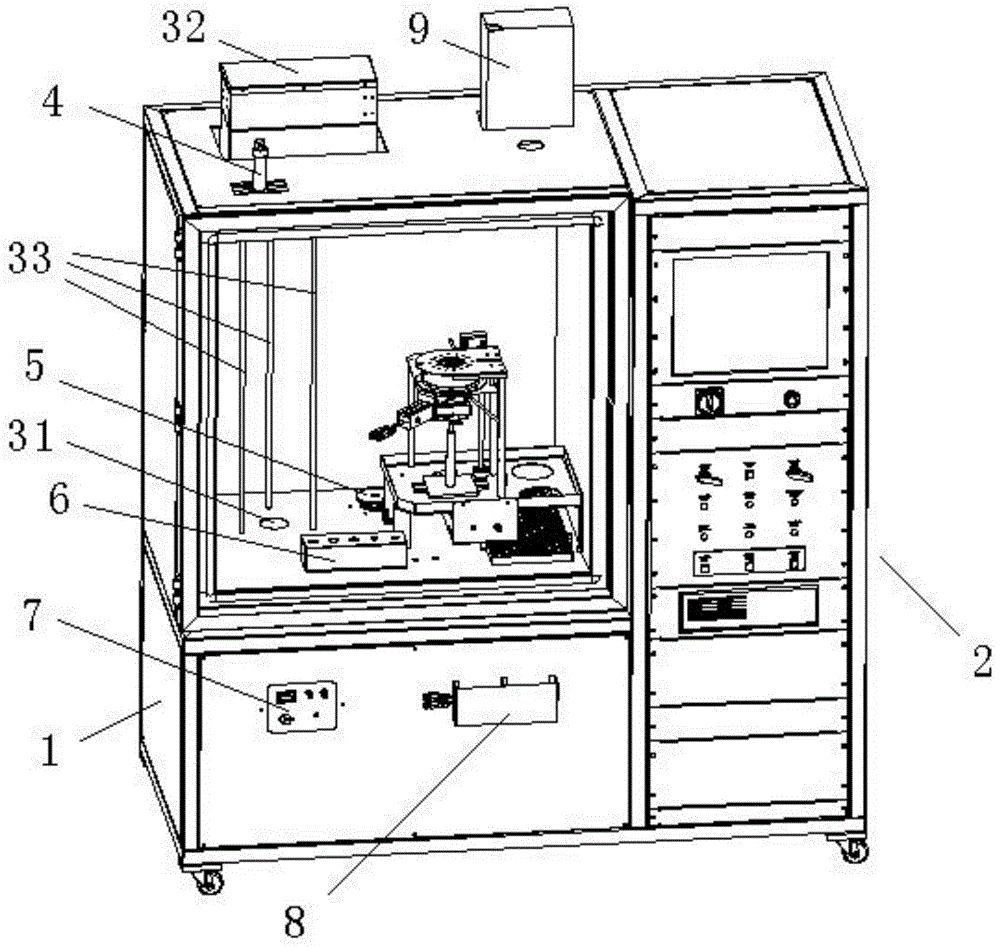

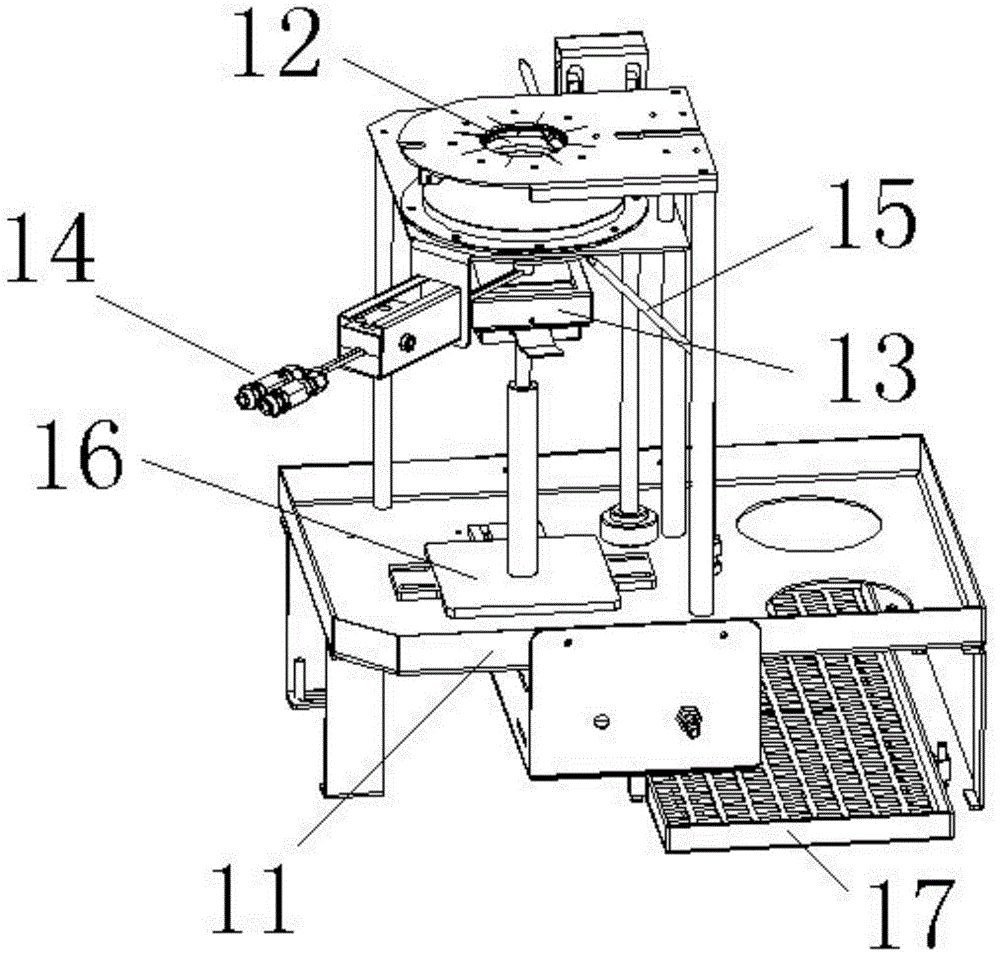

[0021] as attached Figure 1-3 As shown, a kind of smoke density testing device described in the present invention comprises a combustion cabinet 1 and a control cabinet 2; the control cabinet 2 is provided with a display screen 21, a main control board 22, a keyboard case 23, an operation panel 24 and a computer The main engine 25; the combustion cabinet 1 is provided with a sealing door 3, an upper sealing part 4, a lower sealing part 5, a junction sealing box 6, a heat flow meter bracket 7, a heat flow meter water tank 8, a pressure relief assembly 9, a combustion assembly and an optical path assembly ; The sealed door 3 is provided with an observation window 10, and when the sealed door 3 is closed, an airtight space is formed on the combustion cabinet 1; the upper sealing member 4 is positioned at the upper side of the airtight space, and the lower sealing member 5 is positioned at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com